Being one of the most seat of the pants, unorganized wirers around, I have been thinking about my approach (I am in the same spot you are in). Based on my prior experience with wiring a layout and trying to debug it later, here is what I am planning:

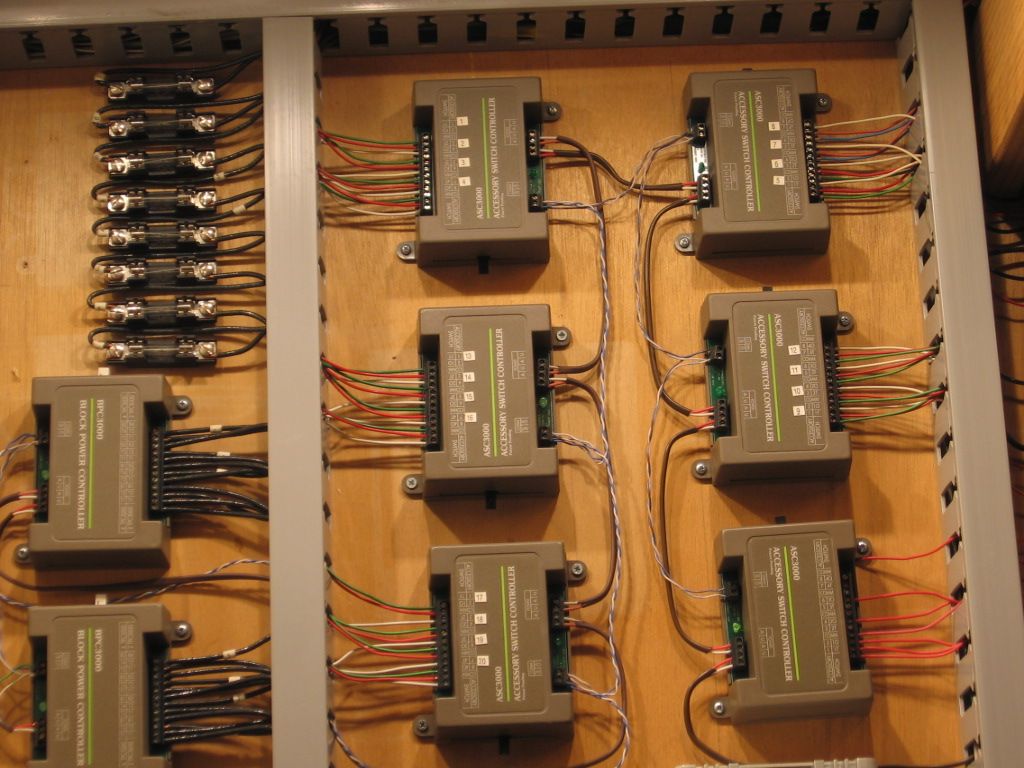

1)color coding the wire beyond white/black/red. So for example, if my blocks have 4 channels (each channel of a ZW), I am going to try and use a different color for each channel/handle. Likely will use pink/black/blue/green (or some such, you can also use wiring with stripes, etc). This is between the transformer and the block selector switch. For the output to the block, I will likely stick with a single color, like red, to the blocks. I also plan on putting labels on the wires to each block at regular intervals, so for example "1" or "block 1". I found the hardest thing was tracking the wire to the track.

2)With the ground side I am going to use a buss, so not doing point to point (I did that on my old layout, I don't know why, brought it back to a jones block near the panel..)

3)In terms of wire gauge, I plan on using 14 for the track feeds (ideally solid core, not stranded), then use 16 or 18 for the drops. Might be overkill, if the 14 looks like it is too hard to work with, I'll switch to 16 gauge for the main feed and 18 on the drops.

4)I am going to use so called suitcase connectors, 3M makes them, but I have seen them at harbor freight and other places. Lot easier than stripping and soldering, oye.

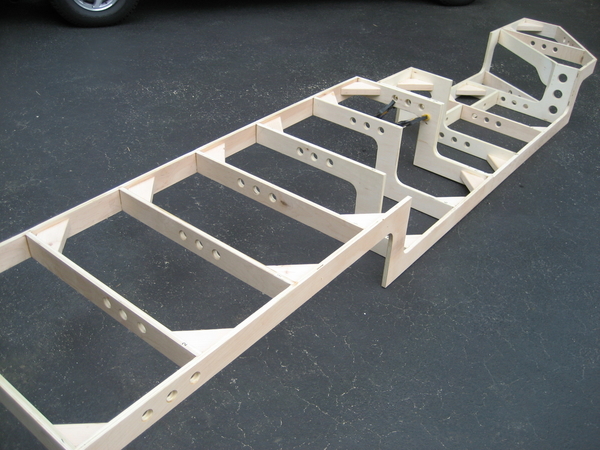

5)Rather than drill through the frame to hold the wires, I am going to use the wiring harness holders , the things with a cylindrical body with a flat leg on each side of the opening, it is screwed to the underside by a screw through the flag legs. Advantage is you can easily open it again to add wires, or pull one out to be able to work on it.

6)Even though I likely won't have command control when I first run the layout, but I plan to wire for DCS (with its own color code, like purple. Trick there is only having one of these connected to the center rail of each block, I'll wire star formation from a jones block. Legacy will be wired through the ground buss.

7)And yep, I'll make sure to order more than I thought I needed, probably order 30% more for the long run wiring. Nice part is, it is never wasted, will be lots of other projects to wire down the line.

8)Even if color coding and labeling, try and create a wiring diagram, over time you may forget the color scheme you were working with! (Kind of like NYC transit, when they built the IND line, the tile on the stations had a color scheme that supposedly could let you know all kinds of things at a glance, only problem is the scheme's meaning has been lost to time from what I recall).