I forgot to press "Post" last night. So here's yesterday's work. Today's will be a separate post.

***************************************************************************************

Thanks folks! Have a ton of images today due to doing several different things concurrently. Titebond needs a good 1/2 hour before you can de-clamp. To fill this time I started working on building the side walls and other sub-assemblies that aren't critical path sensitive. Speaking of critical path, maybe I should put together a Gantt Chart to get my sequencing down before.

It starts with finishing up gluing all the pieces of the floor put together. Straight edge and weight was used to keep it aligned. I put this one up before breakfast. I thought I had spaced the splints to clear the foundation blocks. Turns out that it did need to be trimmed in the mid area to clear, and then more taken off on the outer edges to clear the track ties. More about this shortly.

I did the remaining pieces with the next section being done after breakfast, and then parts 3 & 4 done concurrently when I started my work session later. For the outside piece I clamped it to the table with some Quickie Clamps since other weights were occupied with the next thing I did.

While the floor was drying, I glued on the foundation blocks for the engine house proper. Each had weight applied to hold it until the Titebond dried.

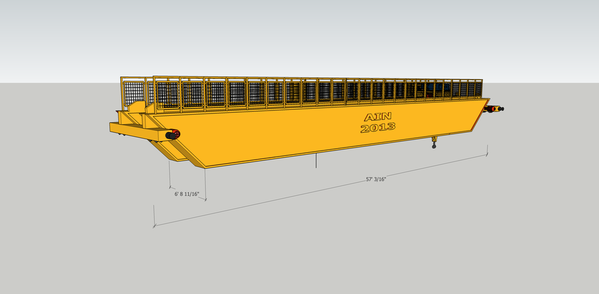

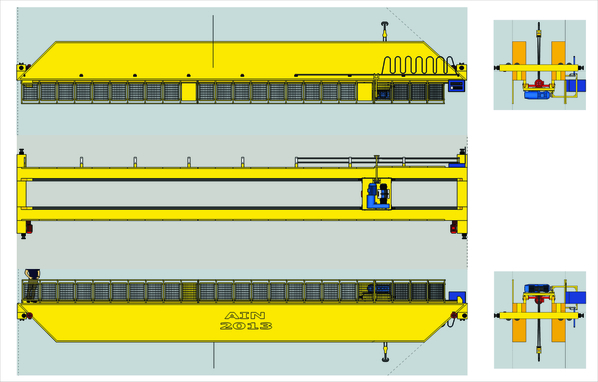

While all this was drying, I started building the gantry crane main girder and traveling rails.

I'm using 3/4" Plastruct I-beams for the crane girders. Three pieces butt glued together was more than enough to go the engine house's full length. I used 0.040" styrene cut in the Duplicutter to the I-beam's web width using Tamiya solvent cement to serve as splice plates. I may added some rivet decals or NBWs depending on hour nutty I want to get on details that will be functionally invisible.

The floor was now fully dry (although) I did bend and break the rear joint that needed regaling (this time with super-glue), and I used it to size the girders. Meanwhile, I realized that I didn't get MDF pieces cut to fill the inter-rail spaces. There wouldn't be any ballasted track visible inside a concrete engine house. I think I'm going to get Stephen to cut these for me since they're so accurate and be of the same material.

I scavenged the rail from some left over Atlas O track. I separated the track from the ties with a MicroMark details shaving chisel and a small hammer and cut the plastic "spikes" on one side thereby releasing the rail.

Using the RSU, I soldered four sections of rail together which, coincidentally, matched the girder length almost perfectly. Won one! I could only find four regular rail joiners and had to use two oxided ones for the center rails. I had to use a wire brush to get rid of most of the oxide since it's not solderable. I used the soldering block and T-pins to attempt to hold it all straight, but still had to bend and tweak it a bit so the rails were nice and straight. The front rail is soldered and the rear waiting to be soldered.

I'm using J-B Weld to glue the rail to the girder. I clamped the assembly to the work surface and it will cure overnight. Tomorrow, first thing, I'll glue up the second girder/rail assembly.

The rail fits the I-beam nicely.

Finally, I started to build the composite buttresses. I had some templates cut while cutting the pilasters. I'm using 3/4" square pine millwork laminated to the pilaster to form the gantry girder supports. Then another extension on top that will support the roof trusses. I thought I had enough material to cut all 16 crane supports and the 32 roof truss supports, but only had enough for the crane supports. I made a trip to Lowe's tonight to pick up another 8 foot piece of 3/4" stock. I did a quick chamfer on the upper edges with the 1" belt sander to dress up that end.

After the floor was removed from the work table, I glued the two halves of the left side together and the inside pilaster which starts the reinforcement process. The joint ultimately gets sandwiched with an outside pilaster so it will be a very strong joint. These pieces too were clamped directly to the table to hold while drying.

I measured the material width with the digital caliper and scribed that distance to the bottom edge of the inside walls parts. I went over this with a pencil and straightedge to highlight it. I glued one of the center and the two end pilasters in place. I figured to add a gantry support block skipping every other pilaster with one more at the center since I have an odd number of pilasters so it didn't divide evenly.

I also scribed centering lines to show where the pilaster go between each window.

The last things I got to today were gluing two gantry support blocks on the ends ensuring that they are perfectly flush with the edges and just had a terrible thought writing this…. The end pilasters need to be one thickness back from the edge since the end walls go between the outer walls. Now I'm going have to break the glue joint. Dang! That ****es me off.

Again, writing this journal clears the mind. I just went down to shop, took my plane blade and a hammer and pried the errant glue-job off. Glued joints are often stronger than the substrate. In this case, one pilaster came off, the other got wrecked. I hope I have extras.

Here's the corrected position, although not glued. I'll do that tomorrow. You know they say measure twice, cut once. Should also add a corollary: Think twice, glue once. This isn't the first time I've had this problem of forgetting which end goes inside which edge. I've done it in design and here I did it in execution.

I tried some engines on the floor and wanted to see if I wanted to put a work platform between the inner tracks would be feasible. Here's what it looks like. A walk could fit, but doubt it would have any railings. It's barely wide enough for a person to stand sideways. I'm thinking that the only work platforms will go on the outsides. Any other opinions?