I recently purchased a poor man's "laser cutter called the Cricut Maker 3 (https://inspiration.cricut.com...ate-cutting-machine/). It uses a knife blade to cut the material I am interested in. In this case 1/16 inch basswood.I have not tried plastic as yet but will do so. The machine plus the knife blade / tool holder along with extra blades plus a couple of super stick pads cost me about $550. I can cut about 11 inches wide by about 24 inches long.

I just set it up today for my first test cut.

https://www.youtube.com/watch?v=WcTaHF-W8rE This video below shows how one user designed the patterns by simply using LibreOffice / Microsoft Office Drawing platform - transferred to Cricut design space for the actual cutting.

You could always pitch it as machine your wife/husband could use for their arts&crafts projects................

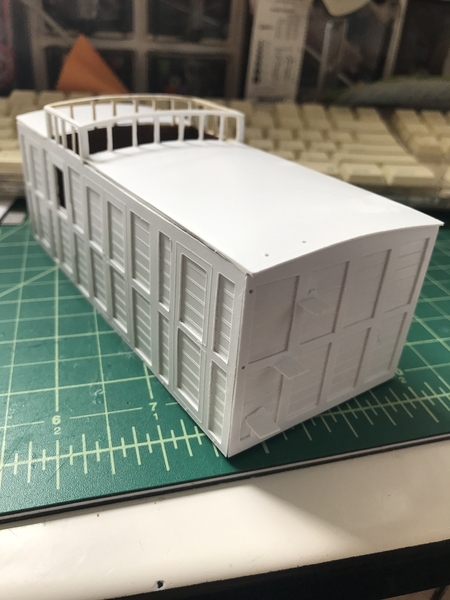

I designed, uploaded and cut my first project. This was a test cut. It consisted of two end walls. The sizes for the openings were taken off the Grandt Line and Tichy web sites. I used LibreOffice Draw to make the basic wall outline then added the openings in the Critcut Design Space. It took about 15 minutes for the machine to cut the walls out. Note the video used Open Office Draw which is different than LibreOffice so I had to export the drawing as a jpg.

The window and door were perfect fits