As I have mentioned in other posts, my layout will consist of two "L" shaped loops, one inside the other.

There will be multiple crossover switches between these two loops.

There will also be several thru track sidings, for a passenger station, along with several dead ended sidings, for industry and storage. The sidings will all be coming off of the inner loop.

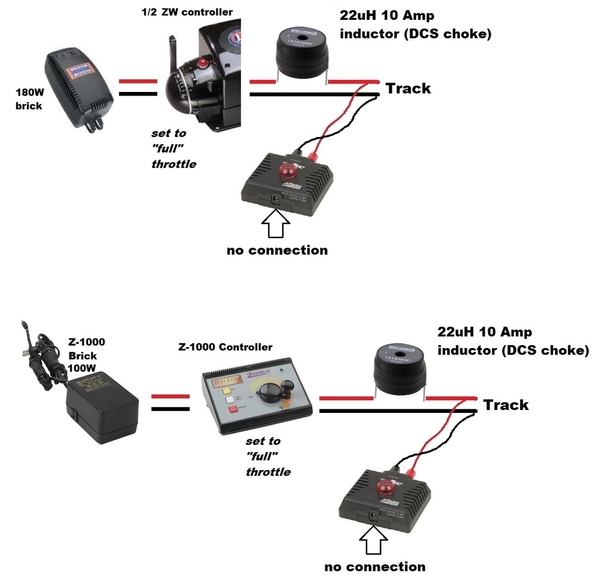

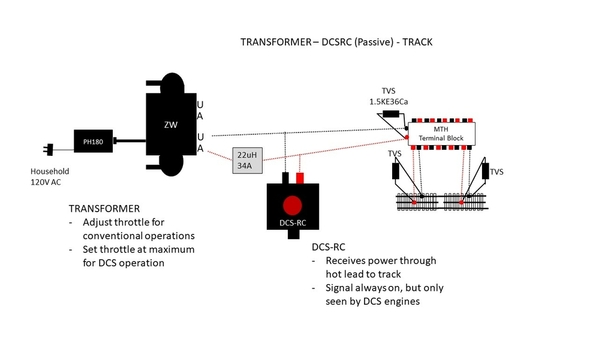

Each loop will be powered by one side of a Lionel ZW with the separate 180 watt bricks.

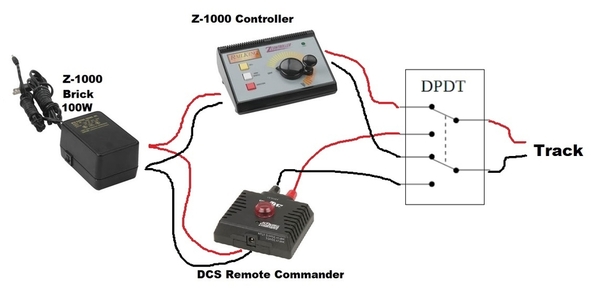

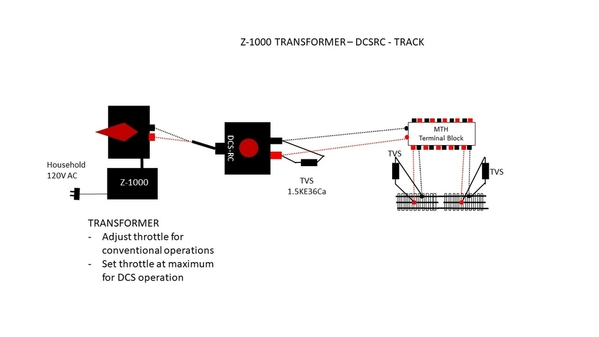

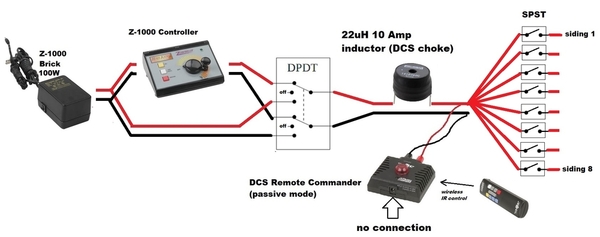

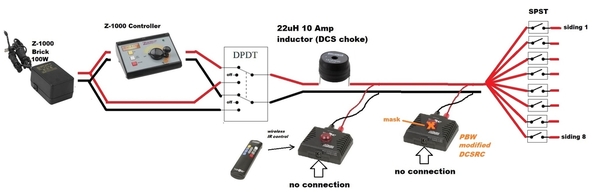

All of the sidings will be powered by an MTH Z-1000, again, with a separate 100 watt brick.

Each of these three three power supply bricks will be wired thru a DPDT switch.

One side of the DPDT switch will send power, from the brick, thru its respective transformer controller.

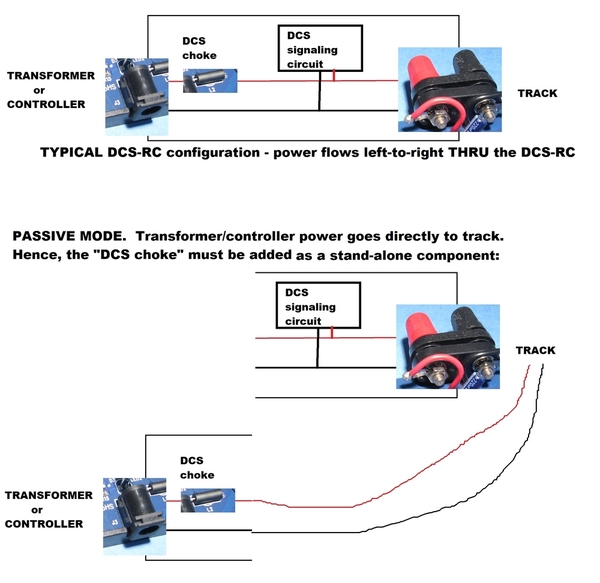

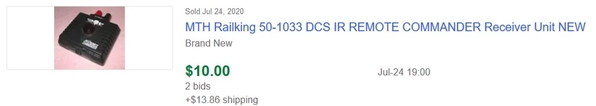

The other side of the DPDT switch will send power, from the brick, directly to and thru a DCS Remote Commander receiver box.

Power will only, ever, be sent to either the Controller or the DCS Remote Commander box, but never both.

How these will be opperated:

1. When running any Lionel conventional, Lionel Lion Chief, or MTH non-DCS locomotives, the DPDT switch will be set to send power thru the transformer controller.

2. When running any MTH DCS locomotive, the DPDT switch will be set to run power thru the Remote Commander receiver box.

NOTE:

The DCS Remote Commander receiver boxes will be placed in a spread out fashion on my L shaped table, such that the remote will, for all practical purposes, be pointed to, and will send signals to only one box at a time. This would be required for the possibility of running separate MTH DCS locomotives on each loop.

All transformers will the phased together.

There will be circuit breakers at each brick.

There will be Diodes at each controller, and each DCS Receiver box, as well as at each track connection location.

I also plan to use non-conductive fiber pins at the center rail at each crossover switch set, as well as at the siding side of each siding switch.

Can anyone think of anything that I have missed, that might be an issue?

Tank you,

Roger