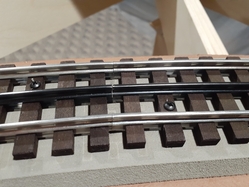

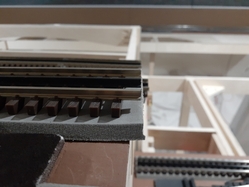

Anyone have some tips on ways to speed up dressing the end of Gargraves track cutoff with a mini chop saw?

I have the Harbor Freight one plus a combination belt / disc sander.

Despite that I end up having to use a jewelers file and a fine jewelers needle nose plier and sandpaper to clean it up.

I have tried Dremel wire brush wheels, but they don't get the flashing and the burrs off unless there is a special one I am unaware of.

There is always the possibility that I am just being impatient.

John