I've read several articles about the usefulness of a helix when you don't have the space for a proper rise. I'm considering one for our upcoming layout, but it seems daunting. And the basic question is - does it even make sense for our circumstances? We have only enough space to use 072 sectional track and, fundamentally, what grade is this going to create between levels when I'd like to maintain approximately 6.5" between levels to ensure no equipment limitations? Does anyone have experience with this?

Replies sorted oldest to newest

There have been prior posts and "How To" posts. They do take up a lot of space.

Hi Don,

I know you're right, but I did a little searching and couldn't find one for grade expectations using 072 and the clearance I'm looking for - I'll look some more.

I built a helix with O63 sectional track and 5.5" spacing, so the incline is about the same as what you are proposing. Here is what I learned:

1) Make sure to figure in the thickness of the sub-roadbed. For example, if the sub-roadbed is 1/2 inch thick, then the helix needs to rise by 7" to create 6.5" of clearance between the top of the lower level and the bottom of the upper level.

2) I used thin right-angle metal brackets to support the sub-roadbed. I thought this would be sturdier than putting screws into the side of the sub-roadbed.

3) It is easier if you screw down your track before you install the next level of the helix above.

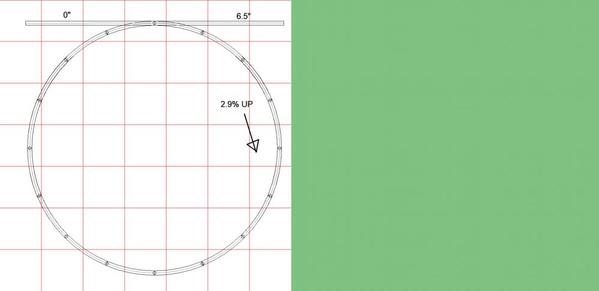

At its simplest, an O-72 helix with a 6.5" rise will require a minimum 2.9% grade, at least according to my RR-Track program. If you add transitions to the grade (you don't go from 0% to 2.9% instantly), the % grade will be more. Ideally you want the transition from flat to grade done on a straight section of track which you need to figure out how to add in. Plus, add in the curve and you are looking at a lot of resistance too.

This is doable in O gauge with short trains, so I guess it depends on what you plan to run.

Attachments

Ron makes a good point about the transition. I put my transition before the beginning of the helix to avoid this problem.

I calculate a 3.45% 2.87% (edit) grade for your O-72 loop with 6.5" between tops of rails.

Thanks for all the feedback.

I would have the transitions on straight leading and exiting track sections - I have about 40" straights I can play with, so no problem there.

A 3.45% grade is way too steep for me to be comfortable - especially when this could lead to problems in an area that's difficult to access. I found on our first layout that everything worked perfectly in easy access spots and just the opposite in areas that were difficult to access. Amazing how that works.

I was reading Linn Westcott's book and I think he advises to use 1/8" overlapping boarding with glue smeared between the boarding to create rigidity. With a 1/4" sub-roadbed I wonder if that brings down the dramatic grade to something more workable?

Thanks again.

I believe the required grade will be 2.8% to rise 6.5 inches from railhead to railhead for an O-72 curve (72" diameter x pi = approximately 226" circumference, and 6.5"/226" = 2.8 %), but you will need to add the thickness of the roadbed. Even if the roadbed is only 1/8 of an inch (0.125") , that increases the gradient to 2.93% (6.625"/226" = 2.93%). That's pretty steep.

PJB posted:...I was reading Linn Westcott's book and I think he advises to use 1/8" overlapping boarding with glue smeared between the boarding to create rigidity. With a 1/4" sub-roadbed I wonder if that brings down the dramatic grade to something more workable?

Remember that Linn Westcott was talking about HO where the trains are feather light compared to most O-scale.

As others have said, for 6.5" clearance from top of railhead to bottom of subroadbed, the grade is actually figured on a railhead to railhead distance. This means 6.5" plus thickness of the subroadbed plus any cork or other roadbed plus the track from bottom of ties to top of railhead. Most brands of track are about 1/2" tall to the top of the rail. Even with track laid directly on 1/4" subroadbed (which I would strongly NOT recommend), you're looking at 7.25" railhead to railhead or a grade of 7.25/226 or 3.2%.

B Smith posted:I believe the required grade will be 2.8% to rise 6.5 inches from railhead to railhead for an O-72 curve (72" diameter x pi = approximately 226" circumference, and 6.5"/226" = 2.8 %), but you will need to add the thickness of the roadbed. Even if the roadbed is only 1/8 of an inch (0.125") , that increases the gradient to 2.93% (6.625"/226" = 2.93%). That's pretty steep.

Yes, 2.87% is correct... I must have hit a wrong number on this tiny calculator last night.

I guess you will have to add the thickness of the ties and rail as well. I forgot about them last night. So if you want 6.5 inches actual clearance between the railhead and the underside of the track board, then the grade is going to be over 3% -- maybe 3.1% - 3.4% depending on height of the rail, thickness of ties, and thickness of track board.