Naptha is the main ingredient in older lighter fluids (Zippo,Ronson, etc), newer Ronson/Zippo formulas seems similar enough I can't tell a difference.

It is listed in PW Lionel text as a plastic cleaner for cars/acc./etc and for cleaning motor parts too.

It is easily brought to flame, but not prone to explode. Rather the flame will want to stay close to the liquid; slow evap as mentioned, long burn time because of that too.

It will give you a headache if you don't vent heavy fumes, but light use isn't a bother imo.

I keep thinking there is an electrostatic solution to this as it seems to part of which wheels get dirty first. Sometimes it's the lead wheels that collect the most gunk, sometimes not. So I figure the track/motor/wheel connection fields are playing with the dust buildup in some near inconceivable and "redundant"(to some) way.

I also think frying food at home has an impact on how sticky dust can be in the house (most (about 90%) of house dust is old skin cells  . Kids and Old Farts leave more behind to be collected). There is also the flange to rail friction adding some slight amount of metal to the electrically charged people dust and settled airborn oils

. Kids and Old Farts leave more behind to be collected). There is also the flange to rail friction adding some slight amount of metal to the electrically charged people dust and settled airborn oils

Post War will have a little more gunk because of brush dust, but I think carbon dust & fields are the real issue.

And maybe the blackness developing isn't as bad as you think (they will "never" remain 100% and a "white glove test" is unrealistic after an hour of running, even in a plastic bubble imo. (that glove is for C-9/C-10 stuff, not rolling stock used as "toys")

Also, you have to clean wheels just as much as track, and if one is dirty and you run , now the other is dirty; dirtier than if you had cleaned everything 100% before running anything at all. Gramps usually cleaned track and then stock before he ran them if they had sat more than a day or two. Maintenance was part of program for him; a habitual replacement after they took his Army rifle and made him walk off the planes again 😬

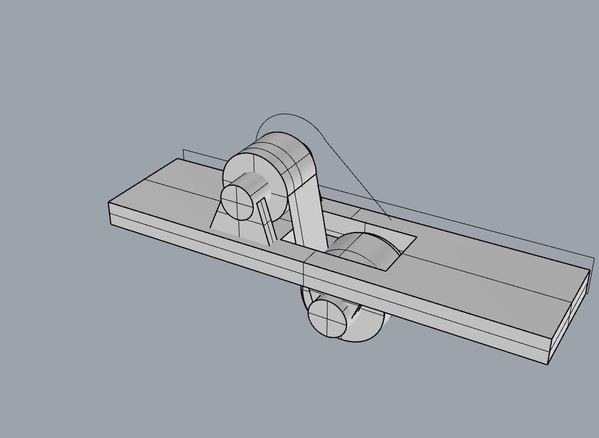

Track cleaning cars are for in-between the hand cleanings imo. It takes a lot of laps to make it worthwhile too. Wet, you'll always have the residue, lack of oil on the metal(none at all = rust and more friction dust) or fumes to consider, and dry scrubs are slow and leave dust on the layout.

Vacuume more too. Put a nylon over the hose to catch small items before they are sucked into the machine; empty the nylon of dust when needed as it acts as a dust bag too. Hold the nylon firmly, it will get sucked out of a rubber band and go into the dust collector. 😲 Sometimes it will hold ok between the brush head and extension/tube too if they are rubbery enough to not slip.