Hello everyone,

When one side and end of your layout table is up against a wall, what is an maximum acceptable width?

Have a great day,

ThomasT

|

|

Hello everyone,

When one side and end of your layout table is up against a wall, what is an maximum acceptable width?

Have a great day,

ThomasT

Replies sorted oldest to newest

ThomasT posted:Hello everyone,

When one side and end of your layout table is up against a wall, what is an maximum acceptable width?

Depends on how strong you built your "table", or how far you can reach. When we built our layout, I constructed the benchwork framing strong enough so that 4 or 5 big adults could be up on top of the 3/4" plywood top at any time, laying track and/or doing scenery. As a result, the one big section that was up against the back wall, was about 12 to 16 feet wide. It was no problem getting up and walking, between buildings, on that area.

Have a great day,

ThomasT

The widest portion of my round-the-wall layout is 3 feet. Most is 2 feet. I used some triangular insets in the inside corners to increase the width so I could use larger O72 and up) diameter curves. The depth there can be 4 feet or more, but the track is no more than 2-3 feet from the edge.

Jan

Most recommend keeping width to 30" to minimize any chance of not being able to reach something without having to climb on it to fix a derailment, clean track, etc. Some folks can reach further, so they go wider and some depends on the height of the decking. Anything above waist high reduces your reach. Others don’t mind using step stools or climbing on top to fix things, add landscaping, etc., so there’s no hard rule. I tend to think of the 30” in terms of reaching track, not thing’s behind it.

Hot Water posted:ThomasT posted:Hello everyone,

When one side and end of your layout table is up against a wall, what is an maximum acceptable width?

Depends on how strong you built your "table", or how far you can reach. When we built our layout, I constructed the benchwork framing strong enough so that 4 or 5 big adults could be up on top of the 3/4" plywood top at any time, laying track and/or doing scenery. As a result, the one big section that was up against the back wall, was about 12 to 16 feet wide. It was no problem getting up and walking, between buildings, on that area.

Have a great day,

ThomasT

Hello Hotwater,

Wow! This will be my first layout and will be inside my house so I do not plan on making it strong enough to walk on. I have a work table in the shop that is just over 3-1/2-ft wide and that is about my max reach. I have one location that the table could be 24-ft long and I was thinking about making it into a "dog bone" shape. On one end it could be 5-1/2-foot wide by 4-1/2' long for a turnaround for 0-54 tracks. Then reduce the width to 3-1/2-ft for 14-1/2-ft long and the other end the same shape and size of the first end.

Thanks for you help and have a great day,

ThomasT

Jan posted:The widest portion of my round-the-wall layout is 3 feet. Most is 2 feet. I used some triangular insets in the inside corners to increase the width so I could use larger O72 and up) diameter curves. The depth there can be 4 feet or more, but the track is no more than 2-3 feet from the edge.

Jan

Hello Jan,

OK, this is close to what I have drawn out in AutoCAD as I have described. I can redraw it and reduce the center portion down to 3-ft.

Thank you, have a great day.

ThomasT

If the benchwork table top is strong enough everything Hot Water said is true. I never thought 18 years ago when I built my layout, it would be such a struggle to climb & bend over. I'm only 63 & arthritis sucks! After 2 knee surgeries, back surgery & a recent hip replacement my 48" high layout is becoming a bit difficult, but not impossible to navigate. 48" is great to work under seated, as well as for storage, but a little difficult to climb onto. Crawling on your knees isn't fun either. My point, reach is also partially determined by height.

My layout space is 13.5' x 36' & I hope in a year or so, my next layout will be lower & walk through, with a 2' to 3' maximum reach. I intend to continue using the around the wall type plan for 3 sides & NO duck unders.

DoubleDAZ posted:Most recommend keeping width to 30" to minimize any chance of not being able to reach something without having to climb on it to fix a derailment, clean track, etc. Some folks can reach further, so they go wider and some depends on the height of the decking. Anything above waist high reduces your reach. Others don’t mind using step stools or climbing on top to fix things, add landscaping, etc., so there’s no hard rule. I tend to think of the 30” in terms of reaching track, not thing’s behind it.

Hello Dave,

I had planned on making the table about 32" high just so that I could reach out to the 3-1/2-ft area but now plan to only make the long stretch 3-ft wide. As soon as my Loco comes in I will make a mock up table and see if I can work the 3-ft. One end will be in a corner but the other end is open except for the wall.

Thanks for you help and have a great day,

ThomasT

ironman1 posted:If the benchwork table top is strong enough everything Hot Water said is true. I never thought 18 years ago when I built my layout, it would be such a struggle to climb & bend over. I'm only 63 & arthritis sucks! After 2 knee surgeries, back surgery & a recent hip replacement my 48" high layout is becoming a bit difficult, but not impossible to navigate. 48" is great to work under seated, as well as for storage, but a little difficult to climb onto. Crawling on your knees isn't fun either. My point, reach is also partially determined by height.

My layout space is 13.5' x 36' & I hope in a year or so, my next layout will be lower & walk through, with a 2' to 3' maximum reach. I intend to continue using the around the wall type plan for 3 sides & NO duck unders.

Hello Ironman1,

Well I have a few years on you, I am 78 and like you having a bit of trouble getting up on things. I wish that I had as much room as you, but hope to make my layout work.

Thanks for your help and have a great day,

ThomasT

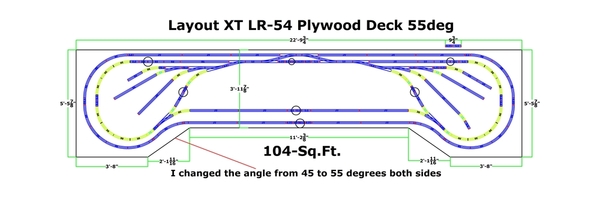

Hello everyone,

This is a pdf drawing of my planned Layout Table. I revised the drawing after the suggestions and help that I received. The two circles denote a 0-54 and a 0-36 scale 3-rail track which can be duplicated on both ends for turnarounds. I have no idea how the rest of the tracks will be installed but will work on some designs.

Thanks everybody for all the good help and advise.

Have a great day,

ThomasT

Tom, corners are why I don’t adhere to the 30” suggestion. The track doesn’t go into the corner and track is all I’d really worry about. Corner landscaping can be placed on removable platforms for easy replacement, cleaning and repair if it’s going to problematic.

Edit: I just saw the pdf and I wouldn’t hesitate to build it even though there might be times you encounter trouble in the corner.

DoubleDAZ posted:Tom, corners are why I don’t adhere to the 30” suggestion. The track doesn’t go into the corner and track is all I’d really worry about. Corner landscaping can be placed on removable platforms for easy replacement, cleaning and repair if it’s going to problematic.

Hey again Dave,

This is just my rough draft and subject to change as needed. Looking at my drawing, the "end" on your left has access from 3-sides, but the other end is in the corner and I only have access to two sides. That outside 0-54 loop could be a problem to reach but I don't know how to work around that. I have some large sheets of cardboard so I might make a model of that corner and see if I could reach a Loco without a step stool. I actually could make a "swing out" stool on a pivot when I weld up the frame???

Really do appreciate all the suggestions, I know as a "Newbie" that I am allowed a few mistakes, but I don't want to use them all up at one time ![]()

Have a great day,

ThomasT

Hi Thomas,

By the way, that's a nice bass! Yeah, its not the age, its the mileage. High school & college sports took it's toll. I know most here would agree that I have a nice amount of space for a layout, but there's never enough room! I like my scale steam engines & will only run 072 minimum but an extra 2 feet in both directions would be nice, mostly for me moving around.

It's hard trying not to squeeze that extra radius in. One of the most important things I've learned is having everything within an accessible reach, especially those turnouts. Its amazing how the hardest places to reach for me are where I have the most problems. A dog bone or folded dog bone is a nice solution for a layout & can offer an isle to walk through.

The important thing is to make it enjoyable & simple helps to achieve that, especially when your older! I like eye level viewing which is why some of my layout is 5 feet high. My next layout will be eye level but while on a chair. I like to just watch them run with my Grandsons, although the older one loves to do switching & he's just 5.

It's all fun, take the time to plan & try not rush it! There is plenty of information out there to get some ideas.

Enjoy,

Joe

Hello Joe,

I am mighty proud of that bass, caught it on a 4-weight fly rod that I had hand made with a "Love Frog" fly, and that Bucketmouth weighted in at 8-lbs & 13-ozs. It took over a week to get that smile off my face ![]()

My original plan was to have all 0-72 track but my space just will not allow that, so I re-sized to 0-54 on the largest track. Just getting started both trains that I have on order will operate on 0-31 and the biggest train on my wish list will operate on 0-54, so I am good for a while.

I am redrawing my layout now with several changes and I will make a mock up and see what needs to be altered.

I am retired and work very hard to have FUN...everyday, all day.

Walking on top of my layout is not an option, so about 3 feet wide for my around the walls layout that is 48 to 50 inches high, is maximum for me.

However, there are 2 places where my layout is 4 feet wide. In those places I left just enough space between the wall and the layout so I can crawl under it, and stand up between the wall and layout (my chest touches the layout when I do this) so I can reach a derailed locomotive or train car.

I do a fair amount of crawling under the layout and reaching/stretching because of derailments, thanks to my 031 curves and Postwar cars. I now think of this as my Yoga and part of my fitness plan, in conjunction with long athletic walks in the State Park near my home that I do every other day.

And, I say to myself when doing my model railroad Yoga, if it doesn't kill me, it's good for me.

LOL, Arnold

ThomasT posted:Hello Joe,

I am mighty proud of that bass, caught it on a 4-weight fly rod that I had hand made with a "Love Frog" fly, and that Bucketmouth weighted in at 8-lbs & 13-ozs. It took over a week to get that smile off my face

My original plan was to have all 0-72 track but my space just will not allow that, so I re-sized to 0-54 on the largest track. Just getting started both trains that I have on order will operate on 0-31 and the biggest train on my wish list will operate on 0-54, so I am good for a while.

I am redrawing my layout now with several changes and I will make a mock up and see what needs to be altered.

I am retired and work very hard to have FUN...everyday, all day.

One of my retirement plans is fishing. You made me laugh with the week long smile comment! I don't blame you for being proud & happy!

You sound like you're being realistic & most engines are good on 0-54 so I'm sure you'll be fine.

Joe

Arnold D. Cribari posted:Walking on top of my layout is not an option, so about 3 feet wide for my around the walls layout that is 48 to 50 inches high, is maximum for me.

However, there are 2 places where my layout is 4 feet wide. In those places I left just enough space between the wall and the layout so I can crawl under it, and stand up between the wall and layout (my chest touches the layout when I do this) so I can reach a derailed locomotive or train car.

I do a fair amount of crawling under the layout and reaching/stretching because of derailments, thanks to my 031 curves and Postwar cars. I now think of this as my Yoga and part of my fitness plan, in conjunction with long athletic walks in the State Park near my home that I do every other day.

And, I say to myself when doing my model railroad Yoga, if it doesn't kill me, it's good for me.

LOL, Arnold

Hello Arnold,

Well you are a better man than I am, crawling under a low table would almost kill me![]() I just made a cardboard mock up with all square corners and set it at 32" high and that inside corner I could not reach but just over half-way. I going to create another pdf drawing with several options and will get it posted here shortly.

I just made a cardboard mock up with all square corners and set it at 32" high and that inside corner I could not reach but just over half-way. I going to create another pdf drawing with several options and will get it posted here shortly.

Thank you for your help.

Hey again everyone,

I am attaching another pdf drawing with couple more changes and another option. I rounded the corners on all outside corners and that helps a little, but the blind corner is still not accessible standing flat-footed![]()

I am showing Plan #2 on this drawing which would be in a different location and have easy access on the entire layout. However it is smaller in square foot surface area. I would appreciate all opinions on this second option vs Plan #1.

Not sure what happened but I will try again to post the pdf drawing

I still vote for #2, but have you thought about removing 18”-24” out of the center and moving the right side away from the corner. That should be enough for you to get in the corner to deal with derailments, etc.

DoubleDAZ posted:I still vote for #2, but have you thought about removing 18”-24” out of the center and moving the right side away from the corner. That should be enough for you to get in the corner to deal with derailments, etc.

Hello Dave,

No, I had not though about that. I will do another re-draw and see how that will look. With the rounded corners I might get by with 16" or so, and that would sure make the layout better. I know that that I will not need to get in that corner very often, so if I have to squeeze in that would be OK. Thanks

DoubleDAZ posted:I still vote for #2, but have you thought about removing 18”-24” out of the center and moving the right side away from the corner. That should be enough for you to get in the corner to deal with derailments, etc.

Hey again Dave,

Presto! I cut 16" out of the center and then rounded both corners on the "wall" end and that allows me to easily reach to the center of the 0-54 track circle. This new design has 90-sq. ft. of surface area so I only lost 9 sq. ft. ![]()

Really do appreciate this suggestions and your time.

What track will you be using?

DoubleDAZ posted:What track will you be using?

Hey Dave,

I will using MTH REALTRAX. If I use the revised version of Plan #1 for the layout I would like to get 3 separate sets of tracks if possible. I do not have any experience laying out a design so I have been following a lot of designs here on the Forum. Boy this Train Hobby sure does get complicated.. he he ![]()

DoubleDAZ posted:What track will you be using?

Hello again Dave,

Now that I have easy access to the entire table, I was able to change the inside corner rdii from the original square to an 18-inch. This greater radius allows the 0-54 / outside track to run a bit closer to the edge of the table and allow three separate tracks. My layout is not very exciting but in time it can be tweaked to include more tracks than just the loops. Thanks again for your help.

For a running layout, it looks good Thomas. You’ve got to start somewhere with what you have and go from there.

Hello everyone,

I am attaching another Revised version of Layout Plan #1. I removed the 3rd set of rails ( 0-36 ) to make more room for some additional tracks for the 0-54 outer run and the 0-45 inter run. The two sets of tracks will be independent of each other so that I can have two Locos running at the same time. This change also gives the Layout a bit more open space for buildings and scenery. I am open to any all suggestions to improve this Layout.

Hi Tom,

First problem is MTH RealTrax has O-42 curves, not O-45.

Second problem is CAD drawings don't always match real tracks.

Third problem is because RealTrax has limited fitter pieces making it difficult to make the loops concentric without cutting tracks to fit.

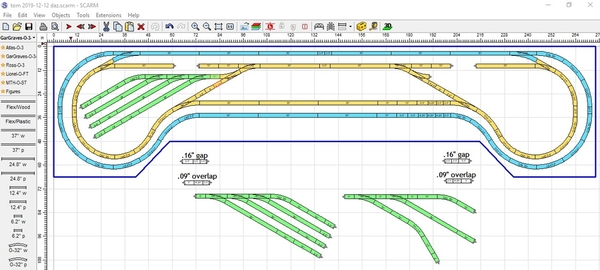

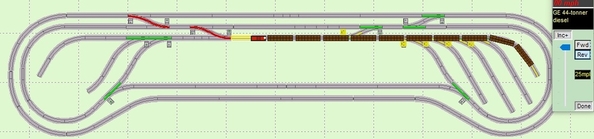

Here's a SCARM rendering of what it would look like with RealTrax O-54 outside and O-42 inside curves. Note I added crossovers so trains can run on both lines. Also note the green tracks should really be O-54 to make the loops concentric, but you'd have to cut RealTrax straights to make things fit. As it is, there are 3 places where the tracks don't join in the software, but I believe they'll join when built.

I've attached a photo so folks can see what we're talking about without opening the PDF and a SCARM file for others who might want to play with the design. I didn't take time to refine the design, just enough to show you what it would look like with actual tracks. Hopefully I didn't make any mistakes, it's only 7:00 here. ![]()

ThomasT posted:Hello everyone,

When one side and end of your layout table is up against a wall, what is an maximum acceptable width?

Have a great day,

ThomasT

Take the heaviest engine you own and place it at arms length at the height of your planned layout and try to pick it up straight. The distance you can do that w/o strain and effort minus the width of the engine is that max width for you.

DoubleDAZ posted:Hi Tom,

First problem is MTH RealTrax has O-42 curves, not O-45.

Second problem is CAD drawings don't always match real tracks.

Third problem is because RealTrax has limited fitter pieces making it difficult to make the loops concentric without cutting tracks to fit.

Here's a SCARM rendering of what it would look like with RealTrax O-54 outside and O-42 inside curves. Note I added crossovers so trains can run on both lines. Also note the green tracks should really be O-54 to make the loops concentric, but you'd have to cut RealTrax straights to make things fit. As it is, there are 3 places where the tracks don't join in the software, but I believe they'll join when built.

I've attached a photo so folks can see what we're talking about without opening the PDF and a SCARM file for others who might want to play with the design. I didn't take time to refine the design, just enough to show you what it would look like with actual tracks. Hopefully I didn't make any mistakes, it's only 7:00 here.

Hello Dave,

Wow and thank you. I was wondering how the layout would actually look with "tracks", and to me that is pretty neat.

OK on my mistake 0-45 v 0-42. Actually the 0-42 works better in the design.

Yes on the mis-match with AutoCAD drawing the tracks, I do covert the lines with "track" in my drawings but it is just a rendition of railroad tracks and not to dimension as in you work.

On the 3rd issue I will take your word for that because I have never worked with RealTrax, but hopefully it can be adjusted to fit on the final real layout.

Thanks for adding the crossovers, see them on most layout but did not know how to insert them in CAD. Man that is a lot of tracks in 90 sq. ft. of table and several good long runs. I like the long runs, thanks again. Your drawing most likely spaced the tracks apart in the correct distance and it appears that a lot of the "building space" is lost. With that said, should I move the top right turnout more to the left to allow more interior open space??

Thank you again so much for all this help.

OH one more thing, does your drawing program produce a list of the individual track pieces??

mwb posted:ThomasT posted:Hello everyone,

When one side and end of your layout table is up against a wall, what is an maximum acceptable width?

Have a great day,

ThomasT

Take the heaviest engine you own and place it at arms length at the height of your planned layout and try to pick it up straight. The distance you can do that w/o strain and effort minus the width of the engine is that max width for you.

Hello MWB,

I do not have any O-scale Engines in at this time but do have two on order. However I do have a G-scale and I did use it yesterday as a test on my cardboard mock up. It was very hard to reach and lift it in that "blind" corner. Dave suggested to remove a section from the middle and open up the blind end and that has solved the problem. I now have easy access on the entire layout. Thank you for this help.

Tom, I’ll take some time today to go through the design to check clearances and see what can be done about the crowding with the spurs. You can move the switch, but let me see how something else will work. I just tried to recreate your drawing as best I could. And, yes, the software can get you a parts list.

DoubleDAZ posted:Hi Tom,

First problem is MTH RealTrax has O-42 curves, not O-45.

Second problem is CAD drawings don't always match real tracks.

Third problem is because RealTrax has limited fitter pieces making it difficult to make the loops concentric without cutting tracks to fit.

Here's a SCARM rendering of what it would look like with RealTrax O-54 outside and O-42 inside curves. Note I added crossovers so trains can run on both lines. Also note the green tracks should really be O-54 to make the loops concentric, but you'd have to cut RealTrax straights to make things fit. As it is, there are 3 places where the tracks don't join in the software, but I believe they'll join when built.

I've attached a photo so folks can see what we're talking about without opening the PDF and a SCARM file for others who might want to play with the design. I didn't take time to refine the design, just enough to show you what it would look like with actual tracks. Hopefully I didn't make any mistakes, it's only 7:00 here.

Second reply to you Dave,

OK on the Green Tracks, I see what you mean and understand the reasoning. You stated there were 3 areas and I see the two Green, where is the third possible problem area.

I realize that this is a small layout but I am very pleased with the way it looks now. Your suggestions has made the necessary changes to get the layout to this point and I thank you.

Now all I have to do is build it ![]()

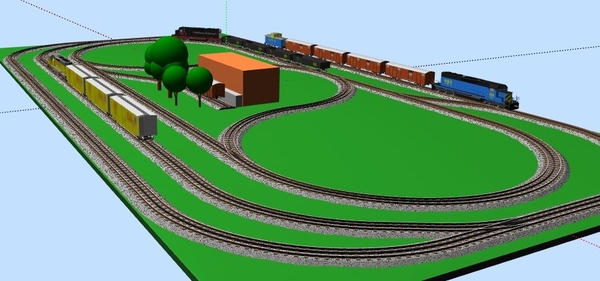

My Real Trax railroad is built upon 37" wide x 72" long x 40" high benches that are clamped together. I use bump-outs cantilevered off of the benches to accommodate the 042 curves and the sidings. Curves and switches are 042. Its flaw is that it is a duck-under to access the the middle of the railroad. I have since connected the Green siding tracks in the upper right corner. The branch line in the upper left is for a future extension that will add more single-end yard tracks for passenger trains.

DoubleDAZ posted:

Hey Dave,

OK that does not look like it should be a big problem and it should go together. As long as the whole assembly is there should be enough "slack" to make up that gap. I am comfortable enough now with the board layout that I will start to work on designing the frame supports that the layout board will sit on. Thanks again Dave I really do appreciate all your help, this part of the project has been a lot of fun.

Bobby Ogage posted:

My Real Trax railroad is built upon 37" wide x 72" long x 40" high benches that are clamped together. I use bump-outs cantilevered off of the benches to accommodate the 042 curves and the sidings. Curves and switches are 042. Its flaw is that it is a duck-under to access the the middle of the railroad. I have since connected the Green siding tracks in the upper right corner. The branch line in the upper left is for a future extension that will add more single-end yard tracks for passenger trains.

Hello Bobby,

Man you have a lot going on with that layout. If and when I outgrow my layout, I would like to have a second level that starts on the first level and a grade that "some" of the engines would be able to climb. Thanks for sharing.

Tom, the 1st photo is a rendering with some changes to the spurs and location of the crossovers. The 2nd photo is another rendering with reversing loops added. The 3rd photo shows a little better way to add the reversing loops. Unjoined tracks are clear, just in different locations. The loops and storage tracks are virtual duplicates of each other in each design.

DoubleDAZ posted:Tom, the 1st photo is a rendering with some changes to the spurs and location of the crossovers. The 2nd photo is another rendering with reversing loops added. The 3rd photo shows a little better way to add the reversing loops. Unjoined tracks are clear, just in different locations. The loops and storage tracks are virtual duplicates of each other in each design.

OK Dave now we have a real problem....I like them all ![]()

Oh boy now I have to decide which one, I sure did not mean for you to go to so much trouble and I thank you for all this work. Between 2 and 3, other than un-joined tracks, they are the same except for the "open" areas. Kind-of-like the staggered open in 2, but also like the "central" main area of open in 3.

This is really cool, had no idea going into this originally that the layout would be this large as far as track space. I will study them over.

I have just completed the upper section of all the angle for the support table. Now I need to work on the vertical columns and then the lower sections. All this lower sections will take a while.

Sure do thank you for these drawings.

Tom, it's a hobby for me and we're watching some Christmas movies on a rainy that don't require a lot of concentration to follow, so it's no trouble.

The difference between #2 and #3 is the crossovers in #3 are on the curves. This eliminates the "S" curves that were there and makes for a much smoother transition through the reversing loops. "S" curves force trains to transition to another direction while part of the train is still going in the opposite direction. This puts stress on the cars and can pull lighter cars off the rails. Given space limitations not much can be done about the "S" curves going into the storage yards, but trains are usually going much slower, so the stress is reduced.

I'd suggest that you break up the symmetry a bit by turning one of the loops into a delivery locale by reconfiguring the yard into service spurs for 2 businesses. Don't pay any attention to the buildings I added, just some I had in the library to illustrate my point.

Thomas T. Good on ya' mate at 78. I'm getting close to 83 and am lucky to still be able to get up on my layout. Also with five hatches and the use of a three-step ladder with a top brace, I extend my reach to about 45". Also, Micromark has a neat helpful ladder with a belly pad to lean over with long feet to go under your benchwork. Solid. My friend has one. My table level is 39.5" with elevated tracks above that. Main table is 12' X 24' with an additional eight-track yard.

Good Luck;

Wally

DoubleDAZ posted:Tom, it's a hobby for me and we're watching some Christmas movies on a rainy that don't require a lot of concentration to follow, so it's no trouble.

The difference between #2 and #3 is the crossovers in #3 are on the curves. This eliminates the "S" curves that were there and makes for a much smoother transition through the reversing loops. "S" curves force trains to transition to another direction while part of the train is still going in the opposite direction. This puts stress on the cars and can pull lighter cars off the rails. Given space limitations not much can be done about the "S" curves going into the storage yards, but trains are usually going much slower, so the stress is reduced.

I'd suggest that you break up the symmetry a bit by turning one of the loops into a delivery locale by reconfiguring the yard into service spurs for 2 businesses. Don't pay any attention to the buildings I added, just some I had in the library to illustrate my point.

Hello Dave,

Boy that looks so much bigger in the 3-d picture and I agree about breaking up the symmetry. It is so early on for me that I really haven't spent much time thinking about the scenery. I have spent a lot of time viewing all 3 of your layout suggestions and I am leaning toward number 3. I will have to find several sources of O-scale features and scenery material. Still working on the support material drawings and should have that completed by tomorrow. Thanks again for all this work.

Cho Cho Wally posted:Thomas T. Good on ya' mate at 78. I'm getting close to 83 and am lucky to still be able to get up on my layout. Also with five hatches and the use of a three-step ladder with a top brace, I extend my reach to about 45". Also, Micromark has a neat helpful ladder with a belly pad to lean over with long feet to go under your benchwork. Solid. My friend has one. My table level is 39.5" with elevated tracks above that. Main table is 12' X 24' with an additional eight-track yard.

Good Luck;

Wally

G'day Cho Cho Wally,

If I had the room I would build a much bigger layout but very happy with what Dave has worked up for me and it will get me into this hobby with a neat layout. I plan to keep my table height down to 32" for easy access and viewing sitting down. I have a neat adjustable chair that I built for my shop and I will use it with the layout and it will adjust down to 6" and up to 35". Thanks for sharing.

Tom, you’re welcome. I look forward to seeing what you end up building.

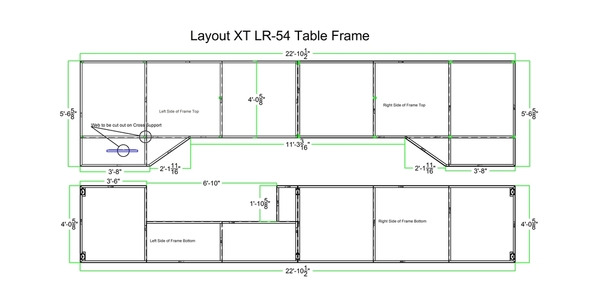

Hello everyone,

I am attaching two pdf drawings of my revised Layout, one is a view of the now larger top surface area (104 sq. ft.), and the second is the Frame Work for the Table. The dimensions are the same except for the center section which is now 4-foot wide ( increased by 1-foot ) and I eliminated all the round corners. Note that I have six (6) swivel casters under the Frame so that the entire Layout can be easily moved in any direction. I will build the Frame in two halves and then bolt them together, and the two halves will share the center two casters.

I received an email from one of the Forum members and he shared his layout drawings and explained that his table was 4-foot wide and he had added casters so that he could service the back side if required.

This latest revision has really improved the overall layout and now will allow a lot more room for scenery items and buildings.

I cannot thank all the forum members enough for the good suggestions and help in getting my first layout up to this point. I especially want to thank Dave (DoubleDAZ) for all the time spent working on various track layouts and suggestions. Dave I plan to use your 3rd design but modify it to fit on the larger layout.

Thomas, my 5x8x11 “L” shaped layout will also be against 2 walls when I hopefully start construction in the spring. I plan on adding casters, so I should have mentioned it, but didn’t think you’d want to move something that big. Just make sure you buy some quality casters.

DoubleDAZ posted:Thomas, my 5x8x11 “L” shaped layout will also be against 2 walls when I hopefully start construction in the spring. I plan on adding casters, so I should have mentioned it, but didn’t think you’d want to move something that big. Just make sure you buy some quality casters.

Hello Dave,

Each caster is rated at 300-lbs and there will be six of them so I should be OK. My plan is to make all the frames out of 1-1/4 x 1-1/4 x 3/16 aluminum architectural angle and the columns will be 1 x 2 x 3/16 aluminum rectangle tube. This frame will be really strong and still be light weight, and of course excluding the decking, foam, and Train equipment. I just completed the CAD drawing for the Frame but have not made a materials list yet. The angle only weights .519 pounds per foot, so a 20-ft joint weights in at only 10.38 pounds. I will try and finish the materials list by tomorrow and work up a total weight and will post it here. It will take a bit of time for the list because I will draw each piece showing all the dimensions and cuts and then label it. I sold my aluminum welder last year so I will have to have a shop do the welding and I will actually pre-cut and label each piece. Then they can fab it up from a "break down" drawing that I will supply. Thank you again for all your help, I am most satisfied with this Layout and cannot wait to get it completed.

Just out of curiosity, wondering if it's recommended or a good idea that an electric train layout be constructed out of metal ?

DoubleDAZ posted:

Hey Dave,

Wow again, that really does open up the interior space which I was wanting. Think I like the second layout the best, again just a bit more open. I copied both along with the parts list and will study them over. Like the yellow line to denote the clearance, that helps me to "see" the track layout better ![]()

I went back and looked at your planned layout and I sure like the 90 degree separation between the two areas.

Thanks again for all this work, very much appreciated.

Richie C. posted:Just out of curiosity, wondering if it's recommended or a good idea that an electric train layout be constructed out of metal ?

Hello Richie,

The way that I have this designed, no part of the Train and train equipment / gear will come in contact with the frame. I will have a plywood sub-floor, then the foam, and then some sort of matt. Along the sides I will add some short ( about 3" high above the ground level ) of wood rail as a protection and a safety feature to prevent any accidental over-run of a miss-guided train or car...he he ![]()

Thank you for your interest.

Is there a concern that some of the wiring underneath the layout may come in contact with the metal frame, especially power supply and transformer wires ?

I'm also wondering how wireless systems like Legacy or DCS might be affected ?

Richie C. posted:Is there a concern that some of the wiring underneath the layout may come in contact with the metal frame, especially power supply and transformer wires ?

I'm also wondering how wireless systems like Legacy or DCS might be affected ?

Hello again Richie,

I am very comfortable working with aluminum and electrical wiring of all types and categories. I am a retired design engineer and spent the better part of the last 45 years designing and building ships, crew boats, work boats, line handlers, etc. and a big part of each vessel was the design and installation of electrical equipment from a simple 120Vac outlet to the latest Radar and Nav equipment. Properly grounded and shielded wiring is quite safe in and around an aluminum structure. As far as the wireless system, the aluminum frame would not have any more effect than the metal tracks or metal train equipment. I appreciate your concern and appreciate your help, after all I am a newbie in this hobby and have a lot to learn from all of the members. Thank you again.

Hello DOUBLEDAZ

I am still reviewing your latest drawings for my Layout and I have a question, are there four spots on the track where there are "gaps". I have circled in red the areas in question. If so, can you tell me the actual size of the gaps and does it pose any kind of a problem. Thanks again for all your help.

Hi Tom.

I did some more fiddling and was able to reduce the number of joints that don't connect to just 1 in each loop. I've tried every combination of RealTrax 5.5", 4.25" and 3.5" sizes and the best I can come up with is either a .16" gap or a .09" overlap.

That said, I can tell you that the default join error in the SCARM software I'm using is .079" and the software was designed for HO-scale track. The RR-Track software I also use at times was designed for O-scale track and has options to .20". If I change SCARM to .20", the joints connect. I have some RealTrax and while I don't have enough to configure a loop like yours, I'm confident there is enough "play" in the tracks for either configuration to work. Also, small gaps can be filled in.

And if you're going to use DCS as your control system, it calls for the layout to be broken into insulated blocks with separate power feeds to each block.

Photo 1 shows both gaps and the optional configuration.

Photo 2 is just a closeup of one side.

Photo 3 shows how I replaced 60 of the 10" tracks with 20 of the longer 30" tracks.

Opinion based on experience:

Is there a reason to be using Real Trax? That can be like running a race with one leg in a cast. These plans of super quality construction with an aim toward permanence just screams GG and Ross to me. Going with GarGraves or Ross track and Ross switches (all made in the USA) will eliminate a host of design problems and open the door for switch configurations unavailable with any imported limited selection track from the big three.

With GG and Ross you could almost use a pen and napkin to design a layout. If you can think it, GG & Ross will make it happen.

As far as fudging Real Trax, DON"T, just go for an overlap design, then remove what ever the overlap is from the center of a section of track then perfectly position them adjacent together on the same flat plane and solder jumper wires from each pad under each end.

Any sectional track should lay as it is determined by it's design geometry. Fudging sectional track can be very painful to one's vision.

Any 1 1/4" gauge track can be added to any other 1 1/4" gauge as long as the rail heads are level, flat and aligned with electrical bonding jumpers.

DoubleDAZ posted:Hi Tom.

I did some more fiddling and was able to reduce the number of joints that don't connect to just 1 in each loop. I've tried every combination of RealTrax 5.5", 4.25" and 3.5" sizes and the best I can come up with is either a .16" gap or a .09" overlap.

That said, I can tell you that the default join error in the SCARM software I'm using is .079" and the software was designed for HO-scale track. The RR-Track software I also use at times was designed for O-scale track and has options to .20". If I change SCARM to .20", the joints connect. I have some RealTrax and while I don't have enough to configure a loop like yours, I'm confident there is enough "play" in the tracks for either configuration to work. Also, small gaps can be filled in.

And if you're going to use DCS as your control system, it calls for the layout to be broken into insulated blocks with separate power feeds to each block.

Photo 1 shows both gaps and the optional configuration.

Photo 2 is just a closeup of one side.

Photo 3 shows how I replaced 60 of the 10" tracks with 20 of the longer 30" tracks.

Good morning Dave,

That looks good to me and I appreciate your extra work. I don't think this will make any difference but when I was drawing each piece of the Frame to label them I realized that I had a bad cut (junction) at the two angle pieces. Anyway I moved them in toward the center by 2" each. Not ever having made a Track Layout before I am unaware of the tolerance allowable so excuse me for my ignorance. I feel confident that this will work fine. Again, thanks so much for all this help.

Thomas, I really like your track plan and always follow anything Dave "DoubleDAZ" helps design. Keep posting as you progress.

Tom Tee posted:Opinion based on experience:

Is there a reason to be using Real Trax? That can be like running a race with one leg in a cast. These plans of super quality construction with an aim toward permanence just screams GG and Ross to me. Going with GarGraves or Ross track and Ross switches (all made in the USA) will eliminate a host of design problems and open the door for switch configurations unavailable with any imported limited selection track from the big three.

With GG and Ross you could almost use a pen and napkin to design a layout. If you can think it, GG & Ross will make it happen.

As far as fudging Real Trax, DON"T, just go for an overlap design, then remove what ever the overlap is from the center of a section of track then perfectly position them adjacent together on the same flat plane and solder jumper wires from each pad under each end.

Any sectional track should lay as it is determined by it's design geometry. Fudging sectional track can be very painful to one's vision.

Any 1 1/4" gauge track can be added to any other 1 1/4" gauge as long as the rail heads are level, flat and aligned with electrical bonding jumpers.

Hello Tom Tee,

From another TT. Tom I am brand new to this hobby and slowly learning new stuff every day. I choose the Real Trax based on recommendations from several folks that I know. At the time I did not know about GG and Ross and have just recently visited the Ross site and reviewed their products. I will check out GG maybe today. I have a bunch of the Real Trax already on order so I will use it on this first Layout and I am sure that it will work very well for me. I really appreciate you suggestions and helpful advice and it should help me when I start to assemble my tracks. It might be a while before I can even get started on the track layout because I'm still working on the design for my table. Thank you again.

Dave Ripp. posted:Thomas, I really like your track plan and always follow anything Dave "DoubleDAZ" helps design. Keep posting as you progress.

Hello Dave Ripp,

Thank you and so am I very pleased that DOUBLEDAZ has spent so much time working with me on my Layout. I love the layout that he has designed and cannot wait to see some trains on it. The long track runs should make a long train look real good chugging along. I will keep posting progress as it occurs, and should have my "frame work" for the table completed in a day or so. I'm going a bit buggy drawing each piece to size and include any and all cuts and then labeling each one. Normally I would build this myself and just work from a 2-D CAD drawing, but I sold my aluminum welder so now I must rely on an outside source to do the welding. Thanks for following along.

Thomas, I was going to ask the same question Tom Tee did, but he beat me to it. 🤪

Anyway, I see you answered the question and I kind of figured you already had some RealTrax on-hand or on-order driving the decision to use it. As for the other things that have been mentioned, just some random thoughts.

While I completely agree that GarGraves/Ross is a better solution in the long run, the smallest GG sectional is 6.4” and they only have full size curves. This limits design options if you limit yourself to sectional pieces and almost always requires cutting if you want to expand the options. However, it’s fairly easy to cut and their flexible track is arguably second only to ScaleTrax in ease of use. Truth be told, the advantage probably goes to GG simply because more people use it and GG/Ross have good customer service.

My chief complaints with RealTrax are noise and keeping it clean. The plastic roadbed generally means noise, so depending on your tolerance level, you might want to consider adding something between the track and the decking to reduce the noise if it bothers you. Some folks use carpet padding, others use cork, acoustic tile, etc. My Christmas layouts were on 1” thick rigid foam on the wood framing, no plywood decking, and it was pretty noisy, though I don’t know how much was the track and how much was the hollow space under the foam. At the time I didn’t know the foam did nothing to reduce noise, but I used it mostly for weight savings. The next year I put the track on top of white batting and it helped quite a bit. I haven’t decided on what I’m going to do for my permanent Christmas display layout, but I’ll be using either Atlas or GG track, and I’m still considering ScaleTrax. Because Atlas and ScaleTrax are solid rail, they’re arguably the quietest.

You might also want to insulate the decking from the metal framing with a rubber/silicone gasket or something. I have no idea how sound transfers with plywood on metal.

When it comes to the 2” mistake you mentioned on the angled braces, please note that there’s no reason the decking can’t overhang the framing if it needs to.

Dave Ripp, thanks for the kind words.

DoubleDAZ posted:Thomas, I was going to ask the same question Tom Tee did, but he beat me to it. 🤪

Anyway, I see you answered the question and I kind of figured you already had some RealTrax on-hand or on-order driving the decision to use it. As for the other things that have been mentioned, just some random thoughts.

While I completely agree that GarGraves/Ross is a better solution in the long run, the smallest GG sectional is 6.4” and they only have full size curves. This limits design options if you limit yourself to sectional pieces and almost always requires cutting if you want to expand the options. However, it’s fairly easy to cut and their flexible track is arguably second only to ScaleTrax in ease of use. Truth be told, the advantage probably goes to GG simply because more people use it and GG/Ross have good customer service.

My chief complaints with RealTrax are noise and keeping it clean. The plastic roadbed generally means noise, so depending on your tolerance level, you might want to consider adding something between the track and the decking to reduce the noise if it bothers you. Some folks use carpet padding, others use cork, acoustic tile, etc. My Christmas layouts were on 1” thick rigid foam on the wood framing, no plywood decking, and it was pretty noisy, though I don’t know how much was the track and how much was the hollow space under the foam. At the time I didn’t know the foam did nothing to reduce noise, but I used it mostly for weight savings. The next year I put the track on top of white batting and it helped quite a bit. I haven’t decided on what I’m going to do for my permanent Christmas display layout, but I’ll be using either Atlas or GG track, and I’m still considering ScaleTrax. Because Atlas and ScaleTrax are solid rail, they’re arguably the quietest.

You might also want to insulate the decking from the metal framing with a rubber/silicone gasket or something. I have no idea how sound transfers with plywood on metal.

When it comes to the 2” mistake you mentioned on the angled braces, please note that there’s no reason the decking can’t overhang the framing if it needs to.

Hello Dave,

As always you are a super nice person and offer good helpful information and I do appreciate all your efforts to help me avoid making BIG mistakes.

Yes, I placed an order for some of the track items a couple of days ago based on your "improved No.3" design and the attached list. I am comfortable with the Real Trax at this time for my first layout. I talked for a long time with a gentleman who has many years and a really large ( actually several ) layouts and he uses the Real Trax and gave me a pretty good run-down about the goods and bads. If I get any more excited about this hobby, I can see moving everything out of my shop which is 10x30 and adding another set of tracks in there. By then I will have a bit more experience and hopefully a bit more knowledge about this stuff and make changes to the tracks if needed.

I have been looking at various materials to act as a "pad" on top of the luan/plywood flooring to help with softening the noise. I have a small piece of an ? rubber / plastic ? open cell material that was used in a work boat that I designed for a company many years ago. Cannot remember the name or even where it was purchased, but I will do a bit more research and will let you know if I find a source.

The mistake was actually where I had three (3) pieces of angle terminating at the same spot. Two pieces joined OK at a 22.5 degree angle but the third piece needed to be scraffed cut so that the top was level with the bottom of the other two pieces. This made for a weird scraff, so I simply moved the Angle piece over and away from the junction and eliminated the weird cut, no biggie, but it does give a tad more deck space and moves that angle a bit away from the curved track.

Oh, I went ahead and ordered 20-pieces of the 30" track and if it is not a lot of trouble I would really appreciate an updated required list of track material for you latest layout. Thanks Dave.

Thomas, since I'm not sure which version you plan to build, and there are 4 possible combinations, I'm attaching parts lists for individual options. To get the overall parts list, add the options you plan to build. Let me know if you have any questions.

Option 1: Base plus Gaps plus Symmetrical

Option 2: Base plus Gaps plus Modified

Option 3: Base plus Overlaps plus Symmetrical

Option 4: Base plus Overlaps plus Modified

Photo of base layout plus options:

Hey again Dave,

The one that I was talking about is from the previous posting "Photo 1" that had the over run. Also you had deleted 60 each 10" and added 20 each 30" tracks.

Good morning @DOUBLEDAZ

I understand that AutoCAD drawings do not convert 1to1 for these track layouts but I think that I can get just a bit more open space in my Layout if this drawings works. See the black circle in the inside corner of the "inset" of the table top. There is a 3/4" clearance between the edge of the Track and the edge of the table the way that I have the Tracks drawn. The "angle" of the inset is currently at 45 degrees, but I can change that to 60 degrees which would move the angle further away from the track and more toward the center of the table. This would allow the Bottom of the Outside Track (0-54) to be closer to in edge of the table ( 2-7/16" on the long run ) thus allowing a bit more Open Space. What do you think?

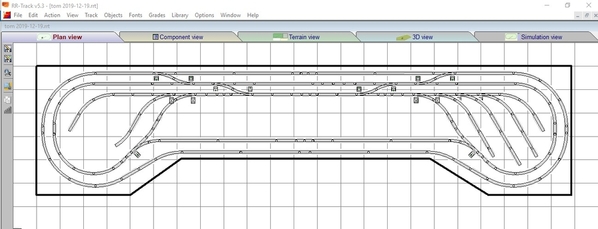

Thomas, I was changing things to add your half curves and after I got done, I ran some simulations and wasn't happy with the play value. The culprit was the placement of the crossover switches, both on the curves like I've had them and on the straights like you've had them.

So, I moved both crossovers to the upper center of the runs. I also moved the storage tracks down a bit so I could move a short straight track between the lead switches to reduce the "S" curve effect.

That resulted in this configuration that allows you to transfer from the outer run to the inner run and immediately reverse the train then transfer back to the outer run. Before you had to travel quite a distance around the inner run to reverse and then transfer back. It was clunky and inefficient.

Adding the half curves was a good suggestion given that you decided to widen the layout. I'm not sure what to tell you about the 45° or 60° braces. In this photo the top of the left 45° brace is at the 5' 4" point and the bottom at the 3'10" point to give you enough clearance at the top. If you want 60°, then the top moves to 5'6" and the bottom to 3' to give you enough clearance at the bottom. There are still 3 places where the tracks don't join in the software. If you want changes or don't like this version, just let me know.

Hello Dave,

I really like the "loop" at the top in the center joining the two lines and all the new open space. If I am seeing this correctly, this new layout also shortens the distance to reverse that direction of the train.

I copied the previous layout and the new layout, one on top of the other into a file and printed it out to compare, and to me it is incredible the change.

Today I will work on redesigning the "top" with 3 options for modifying the angles in the insert (bottom) area. 1) I can simply move the 45-degree angles inward or, 2) change the 45's to a greater angle, 3) a combination of both. Just looking at your layout, I believe changing the angle would be the best way to go. The Casters are due in today and I then can confirm the bolt pattern and I can complete all the drawings for the framework.

Received my first train and two big boxes of tracks in yesterday so I need to get busy and turn these designs into some sort of an actual layout. Once again I want to thank you for all the time you have spent working on this layout.

Hey Thomas- found your thread and just read through it. I like your plan. Good running space and lots of switching to keep yourself busy.

I like your profile photo too. Nice Bass. I helped my son land this beast on Lake George NY about 6 years ago. He wouldn't touch it so this is me holding it at arms length. Caught it right under the dock we were standing on.

Bob

Thomas, it gets a little exciting once parts and equipment start arriving, doesn't it?

Some food for thought:

There's no reason other angles won't work/look better and follow the track more closely if that's your goal. However, I'm still concerned about the "S" curves that were introduced with the move to the half curves and those in the reversing loops. The 3rd photo shows how I redesigned the curves with 10" straights and full curves to eliminate the "S" curves. Yes, it takes away a little space between the blue/gold tracks, but it lets you add a bit of scenery along the bottom and also makes the bottom run a little safer. The photo includes the changes to the storage yards that I mentioned previously.

Here's another version that gives you a larger storage yard on the left and another spur on the right. The purple tracks can be moved higher to more closely match the 1st version.

Jan, you read my mind again. ![]() I had that same version ready to go earlier this morning, but got sidetracked looking at alternatives before I posted it. Then I saw I could accomplish the same thing with the full curves and 10" straights I added in my previous post. I merged the 2 versions and there wasn't enough change in open space to warrant keeping the half curves and the albeit smaller "S" curves. Yes, there's still a small gap, but since tracks are never exactly same time, there are technically always small gaps that aren't seen because there is enough play to close them during assembly......software isn't as forgiving.

I had that same version ready to go earlier this morning, but got sidetracked looking at alternatives before I posted it. Then I saw I could accomplish the same thing with the full curves and 10" straights I added in my previous post. I merged the 2 versions and there wasn't enough change in open space to warrant keeping the half curves and the albeit smaller "S" curves. Yes, there's still a small gap, but since tracks are never exactly same time, there are technically always small gaps that aren't seen because there is enough play to close them during assembly......software isn't as forgiving. ![]()

Thomas, I see I goofed and forgot some tracks in the gold run int he 2nd photo. I'll fix it.........FIXED.

RSJB18 posted:Hey Thomas- found your thread and just read through it. I like your plan. Good running space and lots of switching to keep yourself busy.

I like your profile photo too. Nice Bass. I helped my son land this beast on Lake George NY about 6 years ago. He wouldn't touch it so this is me holding it at arms length. Caught it right under the dock we were standing on.

Bob

Hey Bob,

That is a beautiful fish...however you do disappoint me a bit, a good fisherman would have lied all day long about who caught that fish...he he ![]()

Jan posted:If you insert a 5" straight on the right and left sides of the outer loop where the curve reverse, you will move farther away from the edge and there will be no gap.

Jan

Hello Jan,

Thank you for the help, even thought I'm not exactly sure of that change, I'm sure Dave does. I sure wish that I knew more about this stuff but I guess I am rushing it a bit for only being involved a couple of weeks now. Thanks again.

DoubleDAZ posted:Thomas, it gets a little exciting once parts and equipment start arriving, doesn't it?

Some food for thought:

There's no reason other angles won't work/look better and follow the track more closely if that's your goal. However, I'm still concerned about the "S" curves that were introduced with the move to the half curves and those in the reversing loops. The 3rd photo shows how I redesigned the curves with 10" straights and full curves to eliminate the "S" curves. Yes, it takes away a little space between the blue/gold tracks, but it lets you add a bit of scenery along the bottom and also makes the bottom run a little safer. The photo includes the changes to the storage yards that I mentioned previously.Here's another version that gives you a larger storage yard on the left and another spur on the right. The purple tracks can be moved higher to more closely match the 1st version.

Good morning Dave,

OK brain overload! I will have to copy and print these out and do a long study before I can digest all this new information. However we are on the same page about opening up that center area, see attached drawing that I did this morning. It's not very pretty with 7 gaps/overruns, but hey![]()

OK on the change to the top 2 tracks, I actually like both versions but you understand what is the best for the operation of the train, so I will go with what you say is best.

Yeah about getting in some Trains, just not fair to have to only look at them (: , man I cannot wait to get some track down.

So far I have not been able to contact my friend with the welding shop to see if he can weld up the frame, but if he is too busy I will make it out of mild steel and do all the welding. Thanks so much.

Hey again Dave,

I forgot to commit on the change to the "angles", as you can see I simply changed from 45 to 55 degrees which adds all the needed extra room and it does exactly what you stated, makes the tracks run more in line with the layout. I think it looks great now.

Ok, Thomas. Here is are the latest changes as near as I could reproduce them. I included a closeup so you could see the tracks labels. Note that these version only have 3 areas where the tracks wouldn't join.

Also note that the 1st 2 photos have my version of the bottom blue run with straights and curves that deleted the "S" curves. However, if the "S" curves don't bother you, the 3rd photo has them. I don't know what equipment you'll be running or how fast, so I don't know if curves will be a problem or not. In this version you can't add Jan's 5" straights to ease them though without reconfiguring the loops.

I suspect the symmetry in the 3rd photo might appeal to you, but don't overlook what you can do with the small pocket by the switch in the other photos if you add some bushes, etc.

DoubleDAZ posted:Ok, Thomas. Here is are the latest changes as near as I could reproduce them. I included a closeup so you could see the tracks labels. Note that these version only have 3 areas where the tracks wouldn't join.

Also note that the 1st 2 photos have my version of the bottom blue run with straights and curves that deleted the "S" curves. However, if the "S" curves don't bother you, the 3rd photo has them. I don't know what equipment you'll be running or how fast, so I don't know if curves will be a problem or not. In this version you can't add Jan's 5" straights to ease them though without reconfiguring the loops.

I suspect the symmetry in the 3rd photo might appeal to you, but don't overlook what you can do with the small pocket by the switch in the other photos if you add some bushes, etc.

Hello Dave,

OK I can see right now that I must give up the Train Hobby and maybe take up Quilting! Man this layout stuff will drive me nuts for sure. With that stated, It looks like you have made a near perfect layout, all three gaps/overlaps are so minor that I cannot see them presenting kind of a problem.

I just put together several sections of my new track and although a nice "fit" they surely are not perfect and on a 22-foot run would produce a small bit of discrepancy at lest. So, I surely can live with the minor issues on both of the above.

My next train will not be shipped until after the first of the year and it is a MTH 30-1830-1 O-scale Mohawk / Texas Pacific 4-8-2 and it would run on these tracks all day long. I do not plan on running any of the equipment "fast". And by that I mean real fast, I like the slower chug-chug-chug so none of the curves bother me at this point. I do have several on my list that most likely will only run on the outside track ( if I actually purchase them ) and they are: 20-3755-1 ( shows to work on 0-54 ), 20-3751-1 ( also 0-54 ) and 30-1819-1 a 4-6-6-4 but runs on 0-31.

I had to study and think to see the difference between #2 and #3 but I actually like them equally. I will hold my final decision on that for a bit later. I cannot believe what a big difference increasing the angles to 55-degrees has made in this layout. You have absolutely optimized the surface area and I thank you very much for all this work.

I did receive the Casters in today and the holes lined up perfectly with what I had drawn so I can complete the Frame drawing within a day or two and will post it here. Thank you again....

Ok, I’m eager to see the final layout, so I hope you’ll keep updating this thread.

Hello Dave,

Not to worry, I will keep current any and all work as I progress on this project. I have been studying the current plans and I am so pleased with how this has progressed so quickly, and of course thanks to your efforts. I had thought about some sort of layout but hadn't even decided on a spot so no real plans on how it would look. For the size and shape of the area for my table this latest set of plans have maximized the layout. I should have the Frame drawings completed soon and will post them here.

My buddy Pete, (the welder) I think he is at his ranch in the Hill Country this weekend for a deer hunting trip and hopefully I will hear from him as early as tomorrow night. His business has been so busy all this year that he might not have the time before the end of the year to do the aluminum welding. I just do not want to wait on getting the layout completed so I will do all the fabrication and welding on some mild steel material in my shop. I might do a video on the build and add it to my Youtube Channel.

Dave I sure do appreciate all the kind and friendly help that you have offered on this project, I am 100% pleased with the final layout.

Layout table width

I made mine too wide and am paying for it in terms of access mine is at 160” wide

I made two access hatches but not that great to crawl under layout

it's great you're looking at that now

Best Wishes

Steve Taylor

train steve posted:Layout table width

I made mine too wide and am paying for it in terms of access mine is at 160” wide

I made two access hatches but not that great to crawl under layout

it's great you're looking at that now

Best Wishes

Steve Taylor

Hello Steve,

Thanks to folks like yourself here on the Forum I have been given some good helpful advise and have a layout that should be easily serviced. With the additions of the six Casters it will aide in taking care of the entire "backside" if it is needed. I am getting anxious to get started on building the framework for the layout and then get some tracks laid down. Thanks for your help.

Thomas- may I suggest changing the title on your thread to reflect that you are doing a layout build? I know you started with this as a question but I think more folks will read it with a more appropriate title now.

Bob

RSJB18 posted:Thomas- may I suggest changing the title on your thread to reflect that you are doing a layout build? I know you started with this as a question but I think more folks will read it with a more appropriate title now.

Bob

Hello Bob,

That is a good idea but I do not know how to make that change. Let me see if I can figure that out.

At the top of the page on the right side- click on manage topic. You can edit the title there. ![]()

RSJB18 posted:At the top of the page on the right side- click on manage topic. You can edit the title there.

Hello again Bob,

OK looks like the Title change was made, thanks for the help.

I was just getting ready to post an update so this is good timing.

Hello everyone,

Attached is the final drawing for the Frame Work to build the Layout Table. After several modifications to the original design the surface area is now just over 104 sq. ft. I wish to thank all those who took the time to add suggestions and share your own experience with your layout which in turn helped me with my Layout. I really appreciate all the track layout work that @DOUBLEDAZ did for me.

The frame will be made out of 1-1/4 x 1-1/4 x 3/16 architectural aluminum angle and the columns will be 2 x 1 x 3/16 rectangle tube. It will be made in two sections, a left half and a right half and will be bolted together with Grade-8 hardware. There will be a total of six (6) swivel casters, one on each support corner and two in the middle. This will allow the Layout to be moved away from the wall to gain access to the entire backside for any required service or maintenance.

My plan is to use 3/8 thick Luan plywood for the lower deck surface and that will be covered with some sort of sound proofing material. I will add some material on top of the sound proofing for the final finished look.

I will add progress photos of the various stages on this build up to and including the Track Layout.

Great design.

As a suggestion, you might want to consider adding two more swivel casters (4 on each section). That would make the whole layout easier to move. If you ever relocated that would create more possibilities for moving the layout.

Welcome to the Hobby!

Dallas

Mountain Mover posted:Great design.

As a suggestion, you might want to consider adding two more swivel casters (4 on each section). That would make the whole layout easier to move. If you ever relocated that would create more possibilities for moving the layout.

Welcome to the Hobby!

Dallas

Hello Dallas,

I originally had it drawn that way and when I looked at the overview I saw that the two side-by-side would hit each other during a "swivel" action. I thought about a stagger pattern but that put weight in an un-supported area. I could add a "second" cross frame in each half to separate the casters so they could rotate a full 360 degrees and I will look at that. Thank you for the suggestion.

Hi Thomas,

It was a good suggestion from Bob to change the title since the thread has grown. That said, if I understand correctly, the top and bottom frames will each be built in 2 sections, then joined in the middle. Therefore, I think it makes sense to have a set of casters on each end and in the middle to support the joint. I was going to suggest 4 sets spaced every 2 sections, but then I noticed the bottom frame has a cavity on the left side, presumably to clear something along that wall, so that nixed that idea.

I am somewhat concerned though that the frame is over 4' wide and that means a standard 4' wide sheet of plywood decking won't quite cover it. Your previous photos of the frame didn't include a measurement for the width, but your post on 12/13 suggested it would be less that 4'. In fact, looking at all the dimensions, the frame is slightly larger all over than the baseboard we've been working with. This may be by design, but I thought I'd mention it.

One thing I'm not sure of is if there's enough support in each section to keep the 3/8" plywood from warping when you add rolling stock and buildings. Your sections are approximately 3.5x4 & 4x4 and most folks place cross members every 16"-24". I know you plan to add Homasote or something to deaden the sound and I suspect you'll be fine, I just thought I'd mention it in case someone has experience with 3/8" plywood that size.

Other than that I'm curious to see how the plywood on metal framing works out, I don't remember seeing it before, but I doubt it's a first.

DoubleDAZ posted:Hi Thomas,

It was a good suggestion from Bob to change the title since the thread has grown. That said, if I understand correctly, the top and bottom frames will each be built in 2 sections, then joined in the middle. Therefore, I think it makes sense to have a set of casters on each end and in the middle to support the joint. I was going to suggest 4 sets spaced every 2 sections, but then I noticed the bottom frame has a cavity on the left side, presumably to clear something along that wall, so that nixed that idea.

I am somewhat concerned though that the frame is over 4' wide and that means a standard 4' wide sheet of plywood decking won't quite cover it. Your previous photos of the frame didn't include a measurement for the width, but your post on 12/13 suggested it would be less that 4'. In fact, looking at all the dimensions, the frame is slightly larger all over than the baseboard we've been working with. This may be by design, but I thought I'd mention it.

One thing I'm not sure of is if there's enough support in each section to keep the 3/8" plywood from warping when you add rolling stock and buildings. Your sections are approximately 3.5x4 & 4x4 and most folks place cross members every 16"-24". I know you plan to add Homasote or something to deaden the sound and I suspect you'll be fine, I just thought I'd mention it in case someone has experience with 3/8" plywood that size.

Other than that I'm curious to see how the plywood on metal framing works out, I don't remember seeing it before, but I doubt it's a first.

Hello Dave,

The actual inside dimension on the "4-ft" sections is 4'-1/4" (48-1/4") . The outside dimension is 4'-5/8" but remember the angle is .1875" (3/16") thick per leg / flange so it will wind up being 4'-1/4" inside. I don't know how well my drawing shows the dimensions but that center dimension should read 4'-5/8" and again that is outside.

The frame construction will be in two halves, consisting of an upper section and a lower section and joined together with the vertical columns of 2 x 1 x 3/16 rectangle tube. The "left half" will be welded up as a singular unit and the same for the "right half". The two halves ( units ) will be bolted together at several locations using grade-8 hardware. When the two units are bolted together they will also share 2 of the 4 holes per swivel caster. So they are also held together via the caster plate. I can do a blow-up drawing to better show this if anyone would like to see this detail.

I re-considered the suggestion by Dallas to have 4 each casters per unit to aide in moving each individual unit if the assembly was ever moved and decided to leave it as drawn. The reason being that the plywood deck is not joined in the very center. One sheet overlaps from one unit to the other so if I ever need to disassemble the two units the track and plywood would need to be removed. These frames will not be that heavy ( each unit ) so I do not need the casters to move them. In fact I will not have the caster installed to be able to stand the unit up ( back to top ) to be able to get them into the house. The distance between the bottom frame and the top frame, less the casters, will be 31-1/2" which will clear my standard 36" ( actual opening including the trim is 35" ) doors.

Yes you are correct about the inset on the bottom frame on the Left Unit, it is to clear my fire place on that wall. Not to worry, I don't use the fire place so no roaring fires while the train is on the track ![]()

I think that the 3/8 Luan plywood will be OK, support wise, in the open spaces for a distributed load. Just to be sure I will do a load calculation based on the opening of 3'-10" by 3'-3" and find where the critical loading will be. Thanks for pointing that out, I can easily add a center longitudinal frame and reduce the 3'-10" by half.

I really appreciate the extra "eyes" and experience reviewing my design, thanks again for all the help.

Dave I miss read the first part of your post. The inside dimension of the Vertical "legs" of the Angle is 4'-1/4" but the "flange leg" turns inward by 1.0625", so the ply wood will actually rest on the inside frame. The inside clearance Angle to Angle is actually 4'-1/4" but you have 1.0625" on each Angle turned inward for the plywood to rest on, in other words the "hole" "inside opening is 3'-10-1/8".

Sorry about that, I read what you posted but my brain was asleep ![]()

Thomas, I thought it might be something like that, but I wanted to make sure you didn’t overlook something. When you first mentioned metal I had visions of angle iron bolted together like an erector set. 😱

DoubleDAZ posted:Thomas, I thought it might be something like that, but I wanted to make sure you didn’t overlook something. When you first mentioned metal I had visions of angle iron bolted together like an erector set. 😱

Hey Dave,

Ok so both of our brains went to sleep, wonder if NASA is still looking for some good men ![]()

My 2 cents...

I like the track plan, but even if you can get around to all sides, it looks like some long reaches. Not a fan of the use of casters - unless the benchwork is absolutely rock solid and the floor is perfectly smooth, trying to roll a layout of that size will cause joints to flex which leads to alignment problems, kinked track joints, loose wires, and cracked scenery.

Aside from changing the design, a couple of options are adding some access hatches (hard on the knees) or using a topside creeper (also a challenge). I'm reasonably fit and have used both of those options and regretted them. When I redesign my layout, maximum reach will be about two feet.

Mallard4468 posted:My 2 cents...

I like the track plan, but even if you can get around to all sides, it looks like some long reaches. Not a fan of the use of casters - unless the benchwork is absolutely rock solid and the floor is perfectly smooth, trying to roll a layout of that size will cause joints to flex which leads to alignment problems, kinked track joints, loose wires, and cracked scenery.

Aside from changing the design, a couple of options are adding some access hatches (hard on the knees) or using a topside creeper (also a challenge). I'm reasonably fit and have used both of those options and regretted them. When I redesign my layout, maximum reach will be about two feet.

Hello Mallard4468

Thank you, I have had a whole lot of help with the track layout and just could not be more pleased with the way it has turned out.

The longest reach that I will have will be on the ends and that is only 30" to a very small area. As you can see, the balance of the area within the ends are 24" or less. With a table height of 35" that is an easy reach. Early on in my design work, based on a lot of advice and help from other people, I built a mock-up in cardboard and that is how I wound up with this layout. The majority of the layout, over 16-feet, has a reach to the center of only 24". The framework will have almost no flex in it and the tracks and scenery will be mounted on the Luan plywood which rest independently inside the framework and should not be effected in any way. Thank you for you comment and suggestions.

Hello everyone,

Based on a suggestion made by @DoubleDAZ I have modified both of the Top Frames to include a longitudinal piece of 1-1/4 x 3/16 Flat Bar in the middle of the open framework. This will cut in half the open unsupported area where the 3/8" Luan Plywood will be. The attached picture is for the left side and will be the same for the right side also.

Hello everyone,

I am attaching two new pictures of the Final design for my new Layout. @DOUBLEDAZ has made quite a few "tweaks" to the original design and the result, in my opinion, is the perfect Layout for the size and shape that I have to work with. After I changed the two 45 degree angles on the "inset" to 55 degrees, this gave Dave a whole lot more room to work the Outside Track and in turn a lot more room for the Inside Track. This combination allowed more interior room for scenery and that was one thing I was really wanting. There are more tracks in the rail yard and a cleaner access to each side track. The rail yard (on the right) is now joined directly to the Service Tracks (on the left) and this allows an Engine with up to 10 cars to work off both of the main lines (see photo 2). My general plan for the Layout will be to have three "sections", a) will be the rail yard and some associated businesses, b) the small country town in the center, and c) country side with the two service tracks servicing manufacturing, oil field, mining or similar style of companies.

Thanks to everyone who has taken the time to help by sharing information and suggestions and a special thanks to Dave for all the time and effort he has spent working we me on this project. I will post up dates as soon as I get started on the construction.

Just wonderful, I can't wait to see this go from design to reality.

Dave Ripp. posted:Just wonderful, I can't wait to see this go from design to reality.

Hello Dave,

Now that I have a final layout design I am getting really anxious also. I ordered the last bit of track yesterday and hopefully can get started on the frame as early as next week.

Hello everyone,

Well I will be forced to make some changes to the Table Frame Work because it will not be built out of aluminum as planned. The shop that I had hoped would do all the aluminum welding for me has too many jobs already in progress so they are not accepting any new orders until sometime after the first.