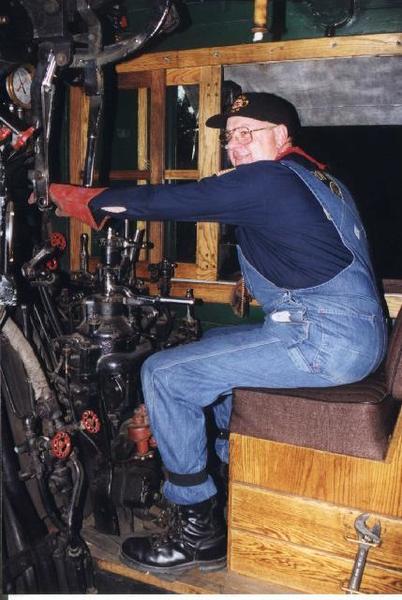

First, I'd like to say, I'm new the Lionel 3 rail family. My brother and I had a 3 rail Marx set when we were kids many years ago. I graduated to N-Scale. But, when the eye sight started to go, so did the N-Scale. My dad had an American Flyer UP 4-8-4 since he was a kid. I did finally get that and that is when I get to re-live my childhood. He would periodically get it out and set it up and allow us to play with it. But, it's only been since last fall I purchased the Lionel LionChief Polar Express for Christmas, that is when I was bitten by the 3 rail bug.

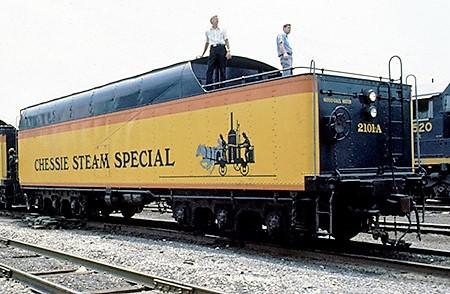

I re-watched a DVD I have on steam trains, it has the history of the Chessie Steam Special on it. I remember this train coming through my home town back in Ohio before I joined the Coast Guard and moved away. I always liked the paint scheme and I'm a steamer fan at heart. So I did a search on eBay and found the Lionel Chessie T-1. I wanted an S-Gauge, but no luck.

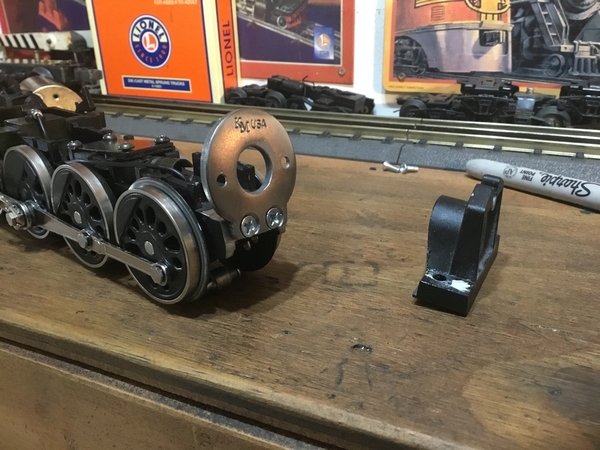

I purchased this engine for $200 plus shipping. I got it and immediately took it apart and found some discrepancies. The front boiler to chassis screw was missing, the firebox light was broken and red lens was missing, and I wasn't sure if the smoke unit worked or not.

So after placing an order to Lionel for some parts, I made a couple of modifications. This is were we take off. Hopefully the pictures and small video work.

I contacted Lionel Support for the diagrams and part numbers for the Chessie. I found that the smoke unit was no longer available.

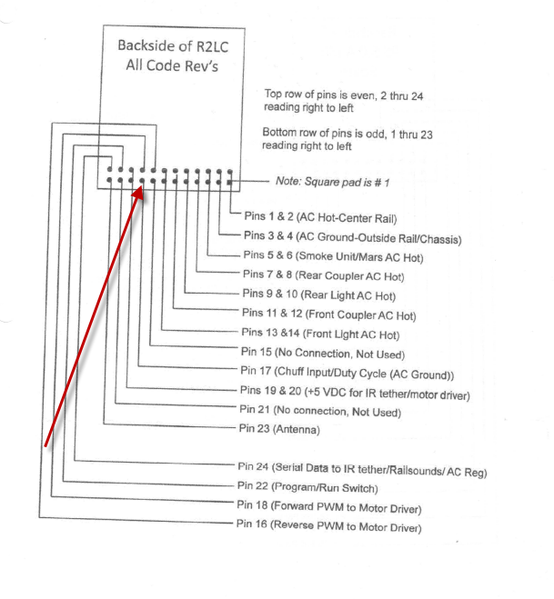

I asked for the L-3 drawings, and received the L3A ones. These are for the NYC 4-8-2 Mohawk 6-18064. Looking at these drawings, This must be for an early TMCC system. But I did notice that most of the hard parts were the same but with different part numbers.

Above is the 2 smoke units side by side. The green one is the OE smoke unit P/N 610-8006-200. This is no longer available. The silver one is the new one P/N 610-8064-200. These are the same. But the tops of the smoke units are slightly different. You can see that there is a hole in the vertical element support. I'm thinking this was put in to help with the problem of too much smoke fluid blocking off the air flow. So, I put one in the OE smoke unit, this is a 1/8" hole.

Next I enlarged the hole for the smoke stack. This I enlarged to the diameter of the stack at the opening. You can see the differences below. I was going to block off the hole for the steam chest but decided to leave it open for now. Then, I removed the 27 ohm smoke element and installed an 18 ohm element P/N 691RS18OHM. I got a new smoke piston since the OE one was sloppy in the bore. The new one is better but not much.

On the first test run of the smoke unit I noticed that the smoke lever was lifting up in the right saddle. So I made a couple of "caps" and JB Welded them to the supports. I didn't scrape off the paint so these should be fairly easy to pop off if I need to. The smoke lever now stays were it's supposed to.

The last modification I did was to replace the front lamp and use an LED. If anyone is interested contact me and I can provide a drawing of circuit. You can see the light in the video.

After I got the engine reassembled, I shot this short video, I'm not to impressed with the smoke unit and piston, because there is a bunch of smoke coming from under the boiler due to the sloppy piston. I used an American Flyer 8B transformer to test run the engine, the CW-80 is on it's way. Since there is no load on the engine, the voltage is very low. You can see the amount of smoke pouring out of the engine. I have considered trying to convert this engine to a fan driven smoke unit and TMCC using the Mohawk part numbers. But I not familiar with any of this technology and don't want to spend the money for it, currently.

Here's the link for the video.