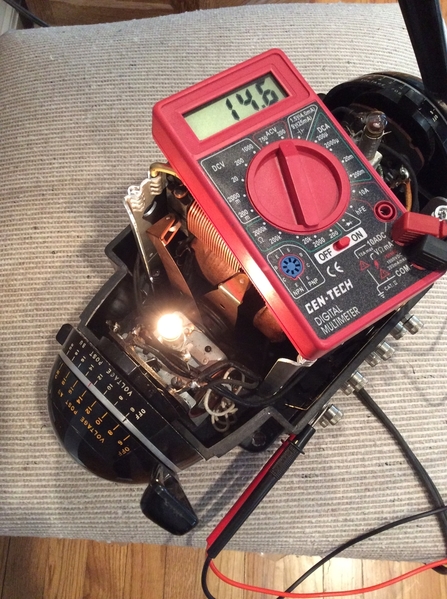

As the old saying goes...cheap usually ends up being expensive. Got a “good deal” on a ZW from our favorite auction site. Two of the posts are dead (One big handle, one little handle) and a few rollers need replacing.

From what I have been able to find online it appears my common buss strip inside the controller is loose. When I use a different ground post the two offending dead posts will come back to life, but only intermittently.

I also have a few rollers that are worn down to a nub. If anyone has a step by step write up they could share with me I would appreciate it. I found a video where the guy crushed the old roller with pliers, cut the old rivet in half and removed it, and then installed new parts and peened the new rivet gently with pliers. Does this sound about right?

Thank you for any help.

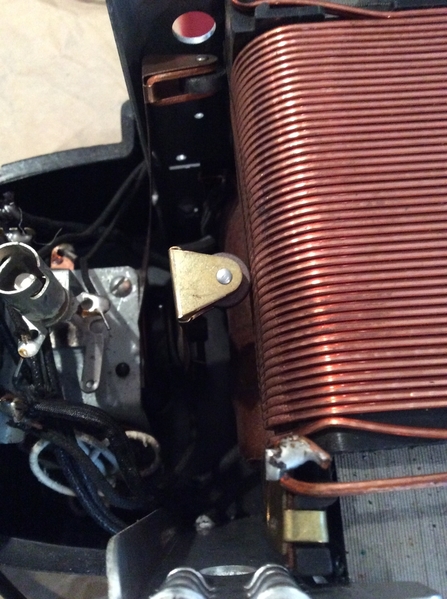

The worn out roller.

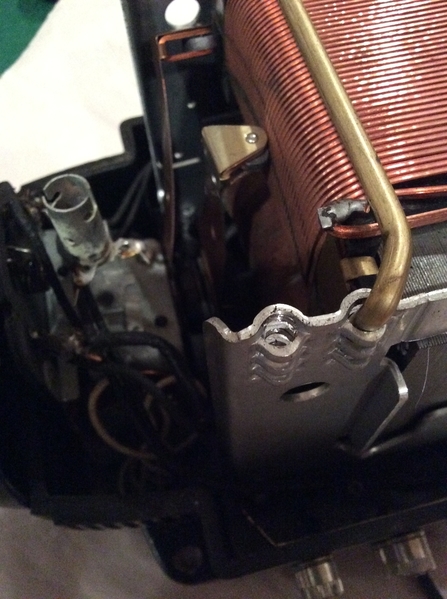

looking straight down at the buss strip you can see it is slightly loose in there.