I don't know if anyone else has ever had this problem but the following is a true story. I thought I would share it with you for Christmas in case someone else has had the same problem.

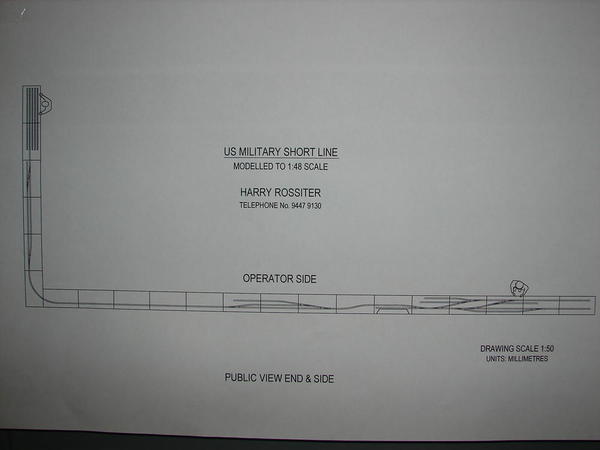

One day I had an idea for a portable layout so I started to build some modules once I started I could not stop and kept building till I ran out of room I even made a jig for the legs and welded brackets onto inch by inch tubing, nothing could stop me the Doctor called it an illness something about a compulsive disorder I thought it can't be to serious because I was enjoying myself I honestly could not understand why my wife and friends thought I was crazy, eventually I got to the track laying stage and a bloke turned up one day to look at my layout in the house, I was working on the modules (I had reached 23!) at the time and he said "what are you doing? are they for sale" I said I don't know I never thought about it, but then he made me an offer and I sold the lot that day now my doctor and wife are happy with me but I never found out where the modules went and if they got finished all I have are the photos. Model Railroading can sometimes have a strange effect on you sometimes but I'm cured ...well.....I have a few new modules in the shed waiting to be finished maybe one day when the wife takes a holiday by herself and the doctor is on leave..

I'll try and find the photos there are lots, I had a camera with me the whole time recording my so called illness. Roo.