I received my 3985 today and tried it on my layout that has Atlas #5 and O72 switches. When the engine passes through the switches at low to moderate speed, the tender loses power and the sound cuts out. I never had any problem with the UP 844, but the roller spacing on its tender is 4.5" whereas the spacing on the new Challenger's tender is only 2.5". All my Atlas switches are the brand new lots that are suppose to have this drop off problem fixed. Anyone else noticing this problem with the Challenger's tender?

Replies sorted oldest to newest

Does it restart? Have seen many Legacy steam engines drop the sound over a switch or crossing and sadly it does not restart automatically like a TMCC engine, it must be "reset" instead. The tender may also be loosing common with the insulated rails involved. It results in the same issue.

installing a 9 volt battery in the tender will keep the sounds going over dead spots, the manual should explain the proceedure.

If the battery Craig mentions helps, Gunrunnerjohn has a permanent solution.

BobbyD posted:Does it restart? Have seen many Legacy steam engines drop the sound over a switch or crossing and sadly it does not restart automatically like a TMCC engine, it must be "reset" instead. The tender may also be loosing common with the insulated rails involved. It results in the same issue.

The tender usually restarts, but it seems like the sound level is lower.

Craignor posted:installing a 9 volt battery in the tender will keep the sounds going over dead spots, the manual should explain the proceedure.

I don't see anything about adding a 9 volt battery in the instruction manual.

Oh-oh, is this the VL Niagara all over again? They changed the position of the rollers on that one as well to accommodate the water scoop feature and the sound cut out on certain Atlas switches. And... the tender does not have a bracket for a conventional 9v battery but I understand some guys added Gunrunnerjohn’s permanent battery device to solve the problem.

Mike

BobbyD posted:Does it restart? Have seen many Legacy steam engines drop the sound over a switch or crossing and sadly it does not restart automatically like a TMCC engine, it must be "reset" instead. The tender may also be loosing common with the insulated rails involved. It results in the same issue.

Another reason I prefer TMCC/RS to Legacy; this flaw is a bit absurd, and I do not put (gonna leak eventually) alkaline batteries in my locos. My Legacy USRA 2-6-6-2 cuts out and stays out; my TMCC/RS USRA 2-6-6-2 (and others) does not. Why is this acceptable? Or even designed?

I do seem to remember being able to do something to get the sounds to re-start short of a power cycle, but I forget what. Haven't run it in a while.

I shouldn't have to "do" anything.

D500 posted:I shouldn't have to "do" anything.

Amen!

Mark in Oregon

Strummer posted:D500 posted:I shouldn't have to "do" anything.

Amen!

Mark in Oregon

I remember quite some years ago, a manager from Lionel, when questioned about operation on Atlas Track, responded, "We design, and test, our products on Lionel Track!". In other words, they don't care about operation on "competitors" track systems.

Hot Water posted:I remember quite some years ago, a manager from Lionel, when questioned about operation on Atlas Track, responded, "We design, and test, our products on Lionel Track!". In other words, they don't care about operation on "competitors" track systems.

I can understand why they made that comment. It would be costly to test products on all other track systems. However, if they design products that won't run on other types of track systems they cut themselves out of a significant portion of potential customers. I purchased the 844 from Lionel and it works fine on Atlas switches. The tender on that engine looks like the same tender on the Challenger so I had no reason to doubt that the Challenger would run perfectly through the Atlas switches also. I suppose there was some reason to shorten the roller spacing by 2". Maybe the problem I am having is unique to my tender sample, but I sure won't be ordering a Big Boy from the next catalog until I see the underside of its tender.

Thank you for the information. I run on Atlas O track with several #5 and O-72 switches. It will save me the aggravation by not ordering the new Lionel Vision Line Challenger.

John Rowlen posted:Thank you for the information. I run on Atlas O track with several #5 and O-72 switches. It will save me the aggravation by not ordering the new Lionel Vision Line Challenger.

You might want to wait to dismiss your purchase until other people check to see if they have the same problem. It is possible that this is an issue with just my tender.

How can you blame the engine. It’s the Atlas switch. Fix it.

romiller49 posted:How can you blame the engine. It’s the Atlas switch. Fix it.

The gap in the center rail of #5 switches is about 3.75" and the pickup roller spacing on the tender is about 2.5". What is your suggestion for a fix on the switch?

I had all kinds of issue with atlas switches which is why I sold all my track and switches and going another route. Lionel has really done a great job to try and fix switch issues with their engines.

Just add another roller on the tender so they are back to back

The problem is a known issue with Atlas. Buy Ross instead and your running trouble free!!

I had some thing like this happen to me.With MTH ps3 and the connector between the tender and the locomotive.I brought it as a christmas present to my self.At some point it would not move the lights and sounds were alright.I sent it back to MTH it came back about a week and a half later.This time every thing worked.It had a note with it that said it was a factory defect.As it turned out I was not alone with that problem.I was happy with the tether.If it not broke do not mess with it.I wonder thou about locomotives that have swinging bells.At some point their gonna run out of room for this extra stuff.Not to mention jack up the price even more.

You pay the big bucks for these monsters and still have to tinker...what the h...!

My Challenger tender drops out on Ross switches too. I could only run straight because I have 054 curves and switches. I'll see what happens when I get too the club. My Allegheny does the same thing on Ross switches.

Jim D,

The problem with Atlas switches was present with the original VL Challenger too. Plus, for those who can remember back that far, those engines shipped with a board defect that meant the battery, if installed, would continue to discharge and power the rear tender lights after the engine was shut down. The boards had to be returned to Lionel for re-programming if you wanted to use a battery without it constantly running down.

I think it was in that context that Lionel said they could not make engines that run flawlessly on every variation of track brand and in particular Atlas. I understand that position. I used to use Atlas but switched back to tubular track.

BTW, the new VL Challenger manual is up on Lionel's website and in common with every Lionel Legacy steam engine I have got from the VL BB going forward, there is no option to install a battery in the tender any more.

D500 posted:Another reason I prefer TMCC/RS to Legacy; this flaw is a bit absurd, and I do not put (gonna leak eventually) alkaline batteries in my locos.

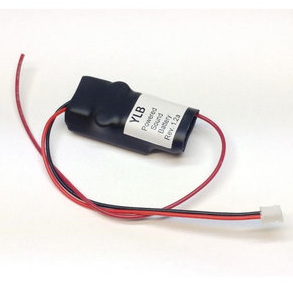

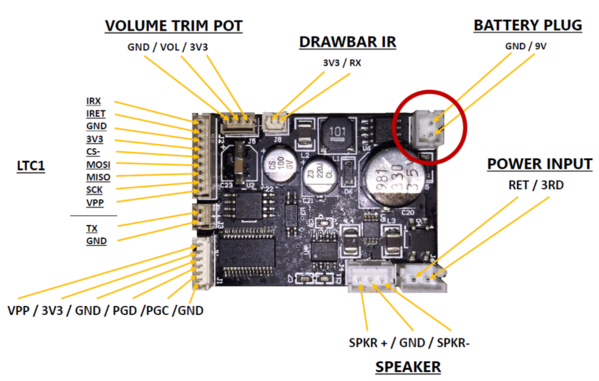

I have a solution for TMCC or Legacy locomotives that have sound issues over switches and the like. The good news is, it doesn't involve leaky alkaline batteries. ![]() You can get them with battery clips for locomotives that have the battery cable, and with the battery connector for direct connection to the RS-Lite audio board for newer Legacy that doesn't include the battery cable. Once and done, install this "battery" and you never have to install another one.

You can get them with battery clips for locomotives that have the battery cable, and with the battery connector for direct connection to the RS-Lite audio board for newer Legacy that doesn't include the battery cable. Once and done, install this "battery" and you never have to install another one.

YLB - RailSounds Battery Replacement

YLB - RailSounds Lite Battery Replacement

Attachments

gunrunnerjohn posted:D500 posted:Another reason I prefer TMCC/RS to Legacy; this flaw is a bit absurd, and I do not put (gonna leak eventually) alkaline batteries in my locos.

I have a solution for TMCC or Legacy locomotives that have sound issues over switches and the like. The good news is, it doesn't involve leaky alkaline batteries.

You can get them with battery clips for locomotives that have the battery cable, and with the battery connector for direct connection to the RS-Lite audio board for newer Legacy that doesn't include the battery cable. Once and done, install this "battery" and you never have to install another one.

YLB - RailSounds Battery Replacement

YLB - RailSounds Lite Battery Replacement

John,

After spending $1700 on the engine I certainly don't have a problem with buying one of these so I can run it. However I have two questions. First, do you think this will void the warranty? Second, I am not skilled as you are in train repair. How feasible is it for a novice to install one of these. I have a vision of opening the tender and having all sorts of things pop out ![]()

Thanks

JFC454 posted:1. It would be costly to test products on all other track systems. However, if they design products that won't run on other types of track systems they cut themselves out of a significant portion of potential customers.

2. Maybe the problem I am having is unique to my tender sample, but I sure won't be ordering a Big Boy from the next catalog until I see the underside of its tender.

1. Think back to the early days of HO scale: the NMRA made d*mn sure that everything could run on everything. Because of that, today you can take 1950s vintage Varney or Mantua and it'll run on Atlas or Bachmann track made yesterday in China. Sure, some deeper wheel flanges may not work on smaller rail sizes, but the focus was to make sure that all products shared the same properties to make for "interchangeability". We saw a similar thought process when it came to that "new fangled" control system, DCC. Too bad that even now, you don't see that in O scale. ![]()

2. I think that's probably wise... ![]()

Mark in Oregon

Hancock52 posted:The problem with Atlas switches was present with the original VL Challenger too. Plus, for those who can remember back that far, those engines shipped with a board defect that meant the battery, if installed, would continue to discharge and power the rear tender lights after the engine was shut down. The boards had to be returned to Lionel for re-programming if you wanted to use a battery without it constantly running down.

I think it was in that context that Lionel said they could not make engines that run flawlessly on every variation of track brand and in particular Atlas. I understand that position. I used to use Atlas but switched back to tubular track.

BTW, the new VL Challenger manual is up on Lionel's website and in common with every Lionel Legacy steam engine I have got from the VL BB going forward, there is no option to install a battery in the tender any more.

As I mentioned before, I understand that Lionel can't design their products to cover all possibilities. What annoys me, is they made the 844 with the same tender as this Challenger except it has a pickup roller spacing of 4.5" CTC instead of the Challengers 2.5" CTC. If they had put the exact same tender on the Challenger as they did on the 844, there would be no problem. There is no problem with the engine part of the Challenger. It has 4 pickup rollers and goes through all my switches without any problem. Atlas has addressed some of their switch problems since the initial Challenger release. I have 14 Legacy diesels and the 844 and not one of them has any problems on the latest run of Atlas switches except for this latest tender.

I had to contact Lionel for longer arm pick up rollers for my K-4 #5432 because it stopped on my Atlas O #5 switches. Check with Lionel Service to see if there is a simple option.

Sincerely, John Rowlen

JFC454 posted:John,

After spending $1700 on the engine I certainly don't have a problem with buying one of these so I can run it. However I have two questions. First, do you think this will void the warranty? Second, I am not skilled as you are in train repair. How feasible is it for a novice to install one of these. I have a vision of opening the tender and having all sorts of things pop out

Thanks

It shouldn't void the warranty, but if you're leery of that possibility, just wait until the warranty expires. ![]()

It's very easy to install these, but you do have to splice one wire, the center roller pickup wire. For Legacy, the white connector plugs into the RS-Lite board, there's only one connector that it will fit. For TMCC or early Legacy with the battery cable, the other model looks like a battery, you just connect the battery clip. With both you have the one wire to the pickup roller to provide the power for the YLB.

Dug through the tubs of old Fastrack I have in the basement and set up 4, O72 Fastrack switches and some 30" straights. Powered a temporary test track with a 180 W Powerhouse. Checked the voltage readings to make sure they were within a few 1/100's of a volt everywhere. With the engine running through the track at crawl speed, the tender cuts out on both LH switches when it goes through a diverging route. The tender does not cut out when going through the RH switches. I thought maybe the wireless link was the trouble. However, when I push the tender by itself through the switches with the power on, the sound cuts out on the LH switches at the same spot, but not with the RH. I think I have two issues. I think there is something wrong with the pickups on my tender that is causing the behavior difference on LH and RH Fastrack switches. I see the same behavior with Atlas O72 switches. I have one LH and 2 RH. Sound only cuts on on the LH one. The other problem of the pickup roller spacing being so short probably can only be fixed with a keep-a-alive product like GUNRUNNERJOHN has made.

JFC454 posted:Dug through the tubs of old Fastrack I have in the basement and set up 4, O72 Fastrack switches and some 30" straights. Powered a temporary test track with a 180 W Powerhouse. Checked the voltage readings to make sure they were within a few 1/100's of a volt everywhere. With the engine running through the track at crawl speed, the tender cuts out on both LH switches when it goes through a diverging route. The tender does not cut out when going through the RH switches. I thought maybe the wireless link was the trouble. However, when I push the tender by itself through the switches with the power on, the sound cuts out on the LH switches at the same spot, but not with the RH. I think I have two issues. I think there is something wrong with the pickups on my tender that is causing the behavior difference on LH and RH Fastrack switches. I see the same behavior with Atlas O72 switches. I have one LH and 2 RH. Sound only cuts on on the LH one. The other problem of the pickup roller spacing being so short probably can only be fixed with a keep-a-alive product like GUNRUNNERJOHN has made.

Thanks for reporting the results of your tests. I am planning a layout with Atlas-O (another thread) with #5s, and #7.5 turnouts, and was concerned about my track choice. I guess I had better purchase a couple and test my existing locos before committing to Atlas-O (Ross/Gargrave looks like my 2nd choice).

Ken-Oscale posted:JFC454 posted:Dug through the tubs of old Fastrack I have in the basement and set up 4, O72 Fastrack switches and some 30" straights. Powered a temporary test track with a 180 W Powerhouse. Checked the voltage readings to make sure they were within a few 1/100's of a volt everywhere. With the engine running through the track at crawl speed, the tender cuts out on both LH switches when it goes through a diverging route. The tender does not cut out when going through the RH switches. I thought maybe the wireless link was the trouble. However, when I push the tender by itself through the switches with the power on, the sound cuts out on the LH switches at the same spot, but not with the RH. I think I have two issues. I think there is something wrong with the pickups on my tender that is causing the behavior difference on LH and RH Fastrack switches. I see the same behavior with Atlas O72 switches. I have one LH and 2 RH. Sound only cuts on on the LH one. The other problem of the pickup roller spacing being so short probably can only be fixed with a keep-a-alive product like GUNRUNNERJOHN has made.

Thanks for reporting the results of your tests. I am planning a layout with Atlas-O (another thread) with #5s, and #7.5 turnouts, and was concerned about my track choice. I guess I had better purchase a couple and test my existing locos before committing to Atlas-O (Ross/Gargrave looks like my 2nd choice).

As information, our entire layout was Atlas O, solid nickel silver rail track system. There were two Lionel articulated models (both SP locomotives, the JLC cab forward #4294 and the JLC AC-9) that exhibited problems with various Atlas turnouts on the layout. I solved the problems by changing out the original equipment pick-up roller assemblies, and replaced them with Sunset/3rd Rail tapered pick-up roller assemblies. End of problems!

I had one MTH NYC L4b Mohawk (the one with the roller bearing rods), that would stop on virtually every turnout. Discovered that the model came with pick-up rollers ONLY on the engine, and none on the tender. I purchased an MTH pick-up roller assembly from the local hobby shop, added to to the tender, and spliced necessary pick-up wire into the correct "hot wire" inside the tender. End of problems.

JFC454 posted:romiller49 posted:How can you blame the engine. It’s the Atlas switch. Fix it.

The gap in the center rail of #5 switches is about 3.75" and the pickup roller spacing on the tender is about 2.5". What is your suggestion for a fix on the switch?

Try adding a small section of rail where the roller loses contact. On Ross switches I’ve had to add track pins to extend the area of contact.

Upon closer inspection I see that the tenders that came with the last run of FEF and the tenders that come with the new Challengers are not identical. Attached are some pictures that show the Challenger tender on the left and the FEF on the right. I read that the real tenders were different with the Challenger tender holding more water. It is hard to see in the pictures, but the Challenger tender is slightly larger than the FEF. The topside detail is also different. I have included a picture showing the relative pickup roller spacings. So, I stand corrected, Lionel could not have just put the FEF's tender on the Challenger model. Now the catalog descriptions for the next release of the Big Boy makes more sense. The "4014 as first run" version will come with a Challenger tender (and likely the short pickup spacing). The "Excursion" version will come with a Big Boy tender which I suspect is the same tender that came with the FEF's and has the wider pickup roller spacing. ericstrains.com does a great job of reviewing various engines and if you look at his review for the Vison Line Big Boy he shows the underside of the tender. The spacing looks the same as that on the FEF's tenders. If that is the case then the Excursion version might run OK through Atlas O #5 switches.

Attachments

This issue can be solved by sharing the locomotive and tender pickup rollers as Hot Water describes. I've done this a number of times, especially with small steamers. I recommend the addition of a 1.5A PTC (programmable fuse) in series with the engine to tender tether, this protects the wiring if you have a derailment and a pickup lands on an outside rail. As for the necessity of the PTC, I've replaced wiring in a few locomotives or tenders that have suffered this exact fate.

Here's one I did and decided to document here:

MTH Switcher Reliability Upgrade

gunrunnerjohn posted:This issue can be solved by sharing the locomotive and tender pickup rollers as Hot Water describes. I've done this a number of times, especially with small steamers. I recommend the addition of a 1.5A PTC (programmable fuse) in series with the engine to tender tether, this protects the wiring if you have a derailment and a pickup lands on an outside rail. As for the necessity of the PTC, I've replaced wiring in a few locomotives or tenders that have suffered this exact fate.

Here's one I did and decided to document here:

MTH Switcher Reliability Upgrade

John the second link get an error might want to check it.

Odd, that's the "perma-link feature", I guess that's broken. ![]()

The tender on the Challenger is now completely dead, no lights or sound. Engine still works fine, its just the tender. So, either the whole problem I started this thread with was due to a faulty sample or running the tender over Atlas O #5 switches is not good for the electronics. I appreciate all the help and suggestions that everyone has given.

Thanks

John Cullen

It's those darned non-articulated sounds, they're killing the sound cars! ![]()

![]()

John Cullen,

Turn the transformer power off. When turning it back on, see if the sound returns to the engine. It should return. If not, try to re-program the engine. I have had steam engines lose sound after repeated interruptions over my Atlas O switches. After several interruptions going over switches, the system shuts down.

The battery should help keep power to the sound system. Lionel may not have put a 9-volt battery cable in the engine tender. If they did, try a 9-volt battery and see if that keeps the sound on when going over switch gaps.

Gun Runner John's rechargeable battery should help with the sound system.

Sincerely, John Rowlen

Excellent thread. My Challenger arrives next week. Hopefully, I can make a positive report.

At $1700.00 plus, there is no excuse for all this aggravation involved'.. SHAME on Lionel...

JFC454 posted:Hot Water posted:I remember quite some years ago, a manager from Lionel, when questioned about operation on Atlas Track, responded, "We design, and test, our products on Lionel Track!". In other words, they don't care about operation on "competitors" track systems.

I can understand why they made that comment. It would be costly to test products on all other track systems. However, if they design products that won't run on other types of track systems they cut themselves out of a significant portion of potential customers. I purchased the 844 from Lionel and it works fine on Atlas switches. The tender on that engine looks like the same tender on the Challenger so I had no reason to doubt that the Challenger would run perfectly through the Atlas switches also. I suppose there was some reason to shorten the roller spacing by 2". Maybe the problem I am having is unique to my tender sample, but I sure won't be ordering a Big Boy from the next catalog until I see the underside of its tender.

I disagree. How costly? How many track systems other than Lionel are out there? MTH? Atlas? Ross? Gargraves? It would be awfully expensive to buy all that track. IMO, what they don't want to do is spend the time and/or effort testing the engines.

And I'm not sure they really cut themselves out of customers. There's this new, neat shiny toy, and we just GOTTA have it. BTO solves the let's see the test results question.

Gerry

John C.,

Were you able to get the sound working again? It has been four days since your last post. I hope you were able to restore the sound. I purchased the Lionel 1931250 Greyhound Challenger #3977. If the sound cuts off on my Atlas O #5 switches, I plan to add the YLB (Your Last Battery) that Gunrunner John sells. When the engine arrives, I will check the tender for a battery clip. Lionel did not include them in recent engines.

Sincerely, John Rowlen

No battery clip needed John, there is a version just for you. ![]() Plugs directly into the RS-Lite battery connector.

Plugs directly into the RS-Lite battery connector.

10510 - Your Last Battery, Railsounds Lite Batt. Replacement

Attachments

When Lionel does the new Boy Tenders, they may want to move the IR board to the center of the tender to allow greater spacing between the pick-up rollers.

Does anyone have the new sound Water Tenders to tell if the pick-up rollers are spaced further apart.

OR … Lionel could easily put female plugs in the rear of the engine and the front of the tender connected to the center pick-up rollers. These would allow buyers to run at wire from both female plugs to connect all rollers. The plugs would not be visible unless they were used with the wire tether. This optional connection would "bullet-proof" the steam engines and avoid different manufacturers' track issues.

Sincerely, John Rowlen

John, I agree with your solutions above but why should lionel add cost their product when it’s Atlas that has the engineering problem with the switch. It is your choice though, and I respect that. I just think Atlas should step up to the plate and correct their switch. With the trains getting more and more complex it’s inevitable that compatibility will continue to be an issue.

Rod, A wise businessman would prepare for all possibilities within their market. Various track footprints is one of those possibilities. The cost for Lionel to issue a call tag, service, then pay to ship the engine back to the buyer for a sound issue is definitely more than installing female pick-up roller plugs in the end of the steam engines and the front of the tender. Lionel could then sell the male-male tether wires as a parts item to recoup some cost. They don't have to give the tether away free, but like good Boy Scouts, "they are prepared" for potential issues customers will face.

Rod, I appreciate your inputs. I am encouraging Lionel to act "Proactively". Customers don't want to know whose fault it is. They want to know what the solution is. I am a strong Lionel supporter. My Lionel purchases prove it. There is always room for improvement on their products. Lionel should be anticipating the potential difficulties and make owning Lionel products easy to do. They do a good job, but is there room for improvement?

Sincerely, John Rowlen

Gunrunner John,

I purchased two 10510 YLB Rechargeable Batteries from Hennings on line today. I called Hennings to see if the batteries could ship today. They were only able to find one 10510 battery in the box. The computer said they had six. Perhaps they sent out the 10510 for the 10500 by mistake. The person looking was not aware that there were two different styles available.

My Vision Line 1931250 Greyhound Challenger #3977 arrives this weekend. I was hoping to have the battery ready to install if/when sound issues occur going over my Atlas O #5 switches.

Thank you. John Rowlen

To be fair, and this is not a criticism of any company:

I've had issues with larger locomotives from Lionel and MTH on Atlas switches regarding power drops.

They all work fine on all other track; even Atlas smaller switches.

romiller49 posted:John, I agree with your solutions above but why should lionel add cost their product when it’s Atlas that has the engineering problem with the switch. It is your choice though, and I respect that. I just think Atlas should step up to the plate and correct their switch. With the trains getting more and more complex it’s inevitable that compatibility will continue to be an issue.

Rod, agree with your above comments. Atlas has known they have various switch problems with various engines, but ignores the problems. Most of their switch problems, roller spacing, rollers getting stuck in rail gaps, etc appears to me can be easily corrected. One would think when ATLAS recently redesigned their switches, they would have made the minor required changes. I love my ATLAS track, but am somewhat disappointed in their switches.

romiller49 posted:John, I agree with your solutions above but why should lionel add cost their product when it’s Atlas that has the engineering problem with the switch. It is your choice though, and I respect that. I just think Atlas should step up to the plate and correct their switch. With the trains getting more and more complex it’s inevitable that compatibility will continue to be an issue.

My tender sample would lose power going through the diverging route of my Lionel LH FasTrack O72 switches unless I reversed the front pickup to increase the spacing. However, in that position the roller was directly over an axle.

John Rowlen posted:John C.,

Were you able to get the sound working again? It has been four days since your last post. I hope you were able to restore the sound.

The tender ran completely dead for 2 days despite trying resets. Then one night while running it suddenly came to life. Since my sample would not go through Lionel's O72 LH switches without loss of power I have returned the engine to Lionel to look at the issue as well as a couple of other problems I had.

John C, Thank you for the update on your 1931260 Challenger #3985. I am glad the sound came back on to indicate that there is life in the sound board.

Since it is back at Lionel, Dean and the technicians will be able to make sure all pick-up rollers are getting power. It should also give the design team a chance to see if a mounting plate with two rollers pointing to the rear of the tender is a possible solution, giving the tender three rollers total. It could get power from the current rear roller feed screw.

I hope this is a case where the customer feedback and Lionel make the product better. The new Big Boys can benefit from this solution finding process. Their tenders are similar.

Sincerely, John Rowlen

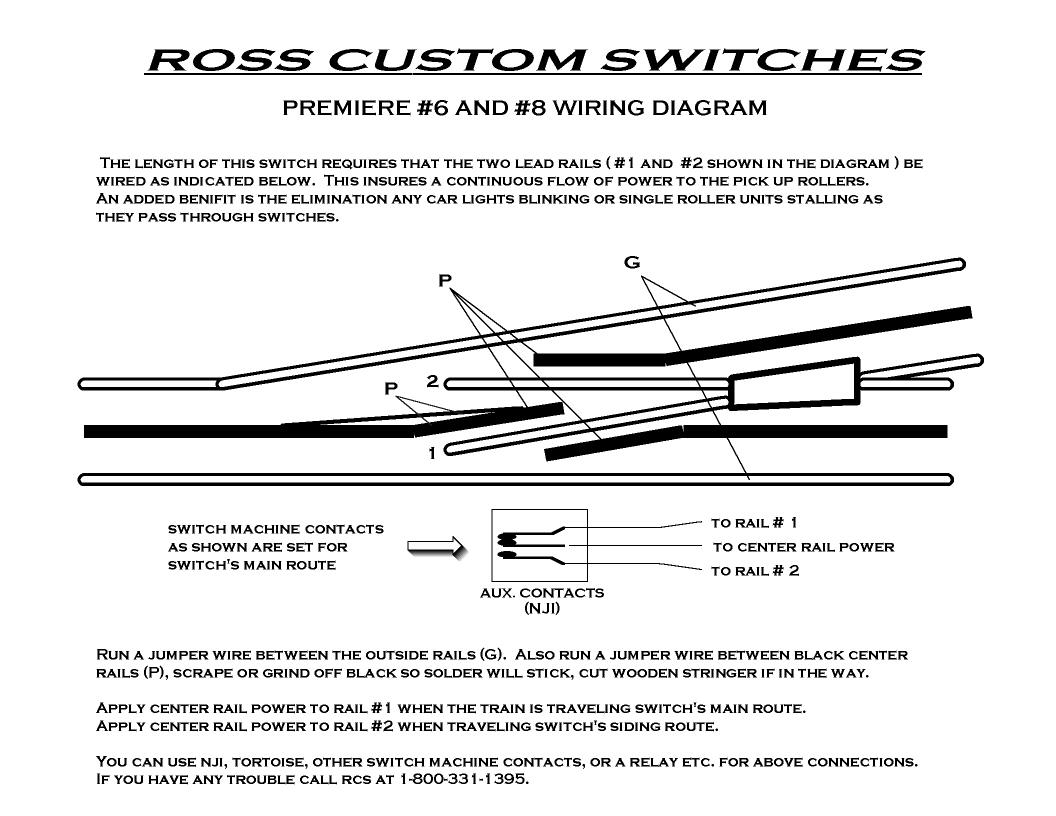

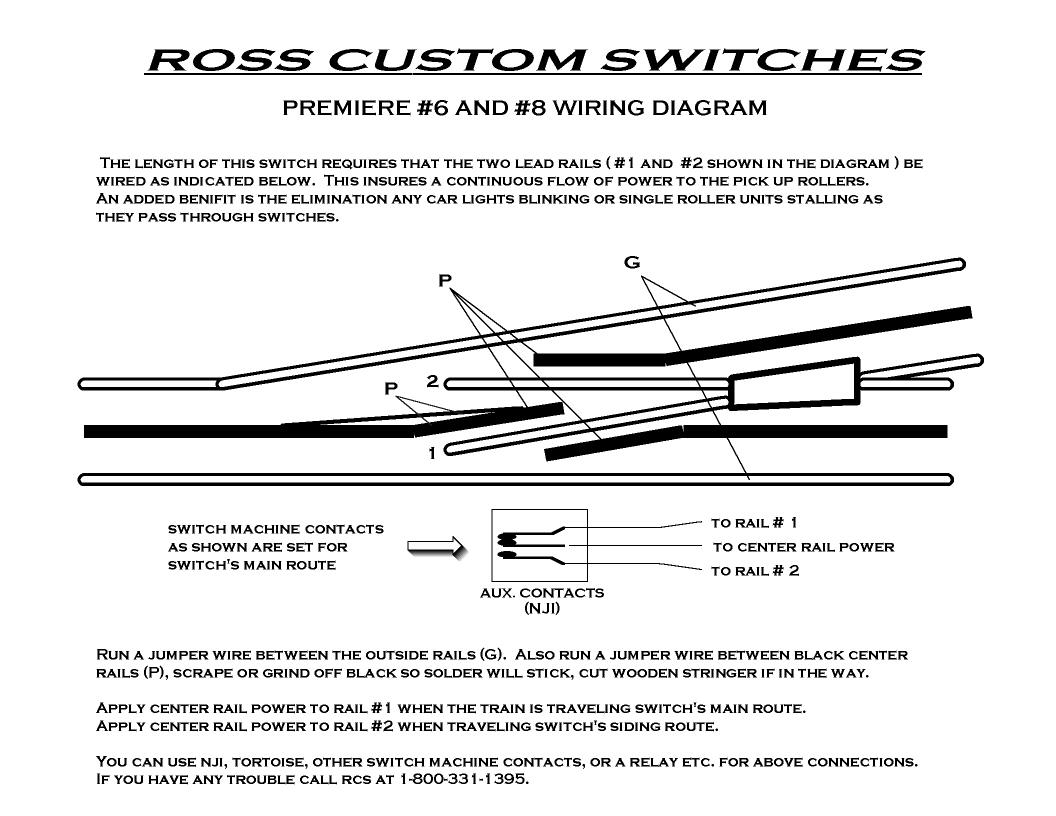

You can power route dead rail sections of switches using DZ 1008 or any latching relays. At one time Atlas provided a relay board that did the same thing. 6924 relay boards.

From the Ross website. Note dead rail one (1) and two (2) and the relay diagram below.

The same can be done with Atlas switches. Automatic non-derail wiring is also required. Best wishes Mike CT. ![]()

![]()

Here is another very good thread. Click on the underlined phrase.

John Rowlen posted:Gunrunner John,

I purchased two 10510 YLB Rechargeable Batteries from Hennings on line today. I called Hennings to see if the batteries could ship today. They were only able to find one 10510 battery in the box. The computer said they had six. Perhaps they sent out the 10510 for the 10500 by mistake. The person looking was not aware that there were two different styles available.

My Vision Line 1931250 Greyhound Challenger #3977 arrives this weekend. I was hoping to have the battery ready to install if/when sound issues occur going over my Atlas O #5 switches.

Thank you. John Rowlen

John,

I just found out today that Henning's was out of the Legacy variety of the batteries, they'll have them in a couple of days. I go by their inventory, and they were lying to me on the website. ![]() FWIW, the locomotive has four pickups I believe, and the likelihood of it having audio cutout is fairly remote, so the one battery in the tender is probably a good move as it's more likely to experience power outages.

FWIW, the locomotive has four pickups I believe, and the likelihood of it having audio cutout is fairly remote, so the one battery in the tender is probably a good move as it's more likely to experience power outages.

romiller49 posted:John, I agree with your solutions above but why should lionel add cost their product when it’s Atlas that has the engineering problem with the switch. It is your choice though, and I respect that. I just think Atlas should step up to the plate and correct their switch. With the trains getting more and more complex it’s inevitable that compatibility will continue to be an issue.

Well, while that might be the "correct" thing to do, I wouldn't hold my breath for Atlas to redesign the switch. ![]()

John Rowlen posted:Since it is back at Lionel, Dean and the technicians will be able to make sure all pick-up rollers are getting power. It should also give the design team a chance to see if a mounting plate with two rollers pointing to the rear of the tender is a possible solution, giving the tender three rollers total. It could get power from the current rear roller feed screw.

Both pick up rollers were getting power because I removed them one at a time and the tender worked when placed on track other than a switch. If you look at the picture of the FEF and Challenger tenders I posted earlier you can see the problem of trying to put a 3rd roller on. The simplest solution would have been to have swapped positions of that LCS track sensor and the rear roller as they did on the FEF tender. At this point the easiest solution seems to be to install one of GUNRUNNERJOHN's devices.

I have several atlas 0-72 switches. I was having a drop problem. The tender had about 3.5 inches between rollers. Should be enough. Tested the point of the switch and the tip has a disconnect from the rest of the point, kind of a joint there about an inch from the tip. There was no power in the tip. So I just cleaned the point of the power rail, and then no more drop. Maybe these rail tips should be soldered to the rest of the power rail?

I looked at my recently acquired Vision Line Niagara, and sure enough, two closely spaced rollers! I'll be using my own product to fix that it appears. ![]()

gunrunnerjohn posted:I looked at my recently acquired Vision Line Niagara, and sure enough, two closely spaced rollers! I'll be using my own product to fix that it appears.

After you make more YLB for the rest of us ![]()

Nuts to that, I come first! ![]() Actually, I'll deliver some to Henning's tomorrow to restock them. They made a mistake on inventory or they'd already have them.

Actually, I'll deliver some to Henning's tomorrow to restock them. They made a mistake on inventory or they'd already have them.

wb47 posted:I have several atlas 0-72 switches. I was having a drop problem. The tender had about 3.5 inches between rollers. Should be enough. Tested the point of the switch and the tip has a disconnect from the rest of the point, kind of a joint there about an inch from the tip. There was no power in the tip. So I just cleaned the point of the power rail, and then no more drop. Maybe these rail tips should be soldered to the rest of the power rail?

When traveling L to R going straight through the switch, when the rear tender roller leaves the point of the hot rail (start of ruler) the front roller is on the beveled plastic tip that is seen on the center rail between 2.25" and about 3.25" There is a hot connection underneath the ruler that you can see sloping downward at just before 3". When the front roller comes to that sloped section its only contact seems to be with the plastic tip. The rear roller isn't in contact with a center rail so the tender loses power. With the front roller reversed, the roller spacing is 8.5 cm which is just at the point where the plastic starts to meet the center rail. Close, but not close enough to maintain power to the tender when the engine is run a low speed. The tender on the recent FEF has a roller spacing of just over 4.5" so it transverses my new run Atlas #5 switches just fine. I think that beveled piece needs to be plastic to avoid the wheel flanges from shorting as they go through the switch. Things are probably even worse with Atlas #7.5 switches. For me, GUNRUNNERJOHN's YLB is probably the easiest fix.

Attachments

Gunrunner John, The first of two 10510 YLB Batteries arrived today. Unfortunately my Challenger that was to arrive yesterday (Thursday) is drifting in USPS for a day and a half since the last scan. USPS thinks I might get it Monday, four days later.

I will put this YLB in my Niagara this weekend. I have a second 10510 Battery that shipped from Henning;s when you re-stocked them the next day. Thanks.

Sincerely, John Rowlen

Yep, I dropped a bunch of the RS-Lite versions off to fill the supply pipeline again. ![]()

I also recently acquired the VL Niagara, and I note the closely spaced rollers. Clearly, this one will also benefit from a YLB to keep the sounds from dropping out.

I don't think these locomotives would need one for the locomotive sound board, they have more pickups there, and sound drops are not really an issue with those.

Gunrunner John, I had not planned on using them in the engine, just the tender. With many steam engines, I will keep you busy making #10510 YLB Batteries with the sound board plug.

Any idea what would make my Allegheny 1604 jerk down the track after reaching speed step 22 ? It runs smoothly at speeds below "22". I know you a repairing one now and are waiting for parts. At the current rate that new items need Lionel Service, I doubt they will ever be able to bring my engine in for non-warranty service.

Sincerely, John Rowlen

Hard to say John, my sense would be either some mechanical issue or perhaps something silly like the flywheel is loose. I wouldn't think it would be electronic with those symptoms.

Gunrunner John,

Thank you for the feedback.

Sincerely, John Rowlen

Gunrunner John's YLB (Your Last Battery) #10510 with the sound board plug fixed the sound drop-out problem with my Atlas O O-72 and #5 switches. The battery quickly charges and provides enough power to the sound system to ride over interrupted center rails.

Below are pictures of the simple process of installing the YLB 10510 Battery. Power for the YLB comes from the screw for the center pick-up roller. No soldier needed, but tighten screw,

Please note that the bundle of wires inside the tender are so tightly bundled with little slack that my tender arrived with the power plug loose and out of its board socket. I had to pull extra gray wire from the bundle to re-connect the plug.

The video shows the sound drop out over an O-72 switch.

My engine still needs service because the Engineer's side rear drivers Ground Light LED does not light. It's always something.

Sincerely, John Rowlen

Attachments

Nice to fix that issue. I have to take my Niagara apart and put one in it as well. ![]()

Was this a cost savings to eliminate the 9volt battery holder and connector?

Well, obviously they saved a few pennies removing the cable/connector and the battery holder. For whatever reason, they thought they didn't need the battery for these models, obviously the guy that made that decision was wrong. ![]() I think all the Legacy stuff no longer has the battery harness or holder.

I think all the Legacy stuff no longer has the battery harness or holder.

John Rowlen posted:Gunrunner John's YLB (Your Last Battery) #10510 with the sound board plug fixed the sound drop-out problem with my Atlas O O-72 and #5 switches. The battery quickly charges and provides enough power to the sound system to ride over interrupted center rails.

Below are pictures of the simple process of installing the YLB 10510 Battery.

Please note that the bundle of wires inside the tender are so tightly bundled with little slack that my tender arrived with the power plug loose and out of its board socket. I had to pull extra gray wire from the bundle to re-connect the plug.

The video shows the sound drop out over an O-72 switch.

My engine still needs service because the Engineer's side rear drivers Ground Light LED does not light. It's always something.

Sincerely, John Rowlen

Thank you for posting the installation photos. Can you clarify where you attached the single red wire that is to be connected to the center rail power. In the picture it looks like it is soldered to a screw that has a black wire attached.

gunrunnerjohn posted:Nice to fix that issue. I have to take my Niagara apart and put one in it as well.

John,

How long will the YLB power the tender electronics once it loses track power? Also, when you shut down the engine using the Cab2, but leave power to the track on, will the tender sound and lights remain on or will they turn off immediately when the shut down sequence completes?

Thanks.

John Cullen

John Cullen, My Greyhound Challenger powers down and the sound goes off even though the track power is still on. I can also shut my transformer off with the engine sound on and the sound shut down in about 5 or 6 seconds with appropriate shut down sounds. This is probably what the battery would do in conventional transformer operation.

Gunrunner John can give you more information. This is how the new Challenger acted with the YLB 10510 battery in the tender.

You mentioned that you lost power to the tender. I found the power plug was out of the sound board socket because the wires were bundled and pulled on the power plug/socket connection. I pulled a little more slack from the bundle and plugged the cable back into the socket. It works fine now. The tender lights also stay on going over Atlas O switches.

Sincerely, John Rowlen

YLB Battery 10510 Power Connection to the Screw for the center Pick-up Roller.

Lionel used a black wire off-center (to the side: Do Not use) and a confusing red and black wire to a center pick-up roller. I fastened the power feed for the YLB 10510 to the Pick-up Roller screw. Make sure no excess wire touches the black screw or tender metal chassis. No soldier needs to be used. The screw should hold it.

Sincerely, John Rowlen

John Rowlen posted:John Cullen, My Greyhound Challenger powers down and the sound goes off even though the track power is still on. I can also shut my transformer off with the engine sound on and the sound shut down in about 5 or 6 seconds

5 or 6 seconds would be long enough to get the tender through the switch dead spot at speed step 1. Just have to be careful not to stop the engine with the tender on the dead spot.

Thanks for the info.

The IR tether is an antiquated holdover from the days when you ran your one chuff per rev postwar tooled toys 400mph all over the place. Why Lionel can't at least use the nice tethers they put on the second gen 0-8-0s with the copper spring contacts is beyond me. At least supply an optional jumper plug to tie all the rollers together.

I also hate to tell you guys, but all three rail turnouts have power gaps. If you are not feeding power to all sides of a turnout you're not even doing the bare minimum effort to make your layout right.

The YLB powers a RS board for anywhere between around 5 seconds to over 10 seconds when fully charged. The time depends on the volume of the sounds and the 'density" of the sounds. Obviously, a loud whistle blowing will deplete the battery faster as that consumes more power to generate the sound. The intent of the product was to allow continuous sounds for brief track power interruptions, and also for conventional operation to have continuous sound for direction changes. I've heard it complete shutdown sounds on some locomotives with power off, and cut them short on other locomotives when power was removed. I can only guess the ones that get cut off are pulling more power from the YLB.

Gunrunner John,

Henning's Trains only has four 10510 YLB Batteries left in stock. They sold five since last night. I plan on installing the 10510 YLB Battery in every steam engine in my collection. I will be removing standard batteries that can leak, especially in the costly articulated engines. Some of my display engines have been sitting with regular batteries in them for three years.

Sincerely, John Rowlen

Not to worry John, there's more where they came from. I just have to do the packaging and get them ready, but we're not running out yet.

gunrunnerjohn posted:Well, obviously they saved a few pennies removing the cable/connector and the battery holder. For whatever reason, they thought they didn't need the battery for these models, obviously the guy that made that decision was wrong.

I think all the Legacy stuff no longer has the battery harness or holder.

Well bring some YLB's to York John, looks like its going to be a hot item.

From what I'm hearing, I think that will be the major production item! ![]()

Gunrunner John, I am opening my Niagara #6013 Tender and putting my last 10510 YLB Battery in the Tender and replacing a traction tire that Lionel sent me.

I got a call from PayPal after ordering three more 10510 from Henning's Trains. They wanted to know if the purchase was made by me because it is similar to my previous purchase. It was all automated. I confirmed I ordered by pressing "1". Then twenty minutes later, PayPal called wanting to know if I made the same purchase. I confirmed that I did. Something is screwed up at PayPal. My last $490.00 payment that was made on August 9, 2019 is no longer listed in my account, and cleared my bank. My $400.00 August 2nd payment is there. I am noticing a lot of stress when I deal with the two local banks I use. One banker was really stressed when the DOW dropped and she lost almost half of her IRA. There are riptides in the financial system. Remember to swim parallel to the shore.

Sincerely, John Rowlen

gunrunnerjohn posted:From what I'm hearing, I think that will be the major production item!

Do you have a frequent buyer deal? buy 5, get the 6th free?

I had a go-round with PP once like that, they didn't know which end was up. We finally got it sorted out, but left a bad taste.

Gunrunner John,

I installed the second YLB 10510 in my Vision Line Niagara. The job took more time feeding the power wire through the tender floor and under the pick-up roller plate. I tried to wrap it around the pick-up roller screw, but had the nut fall back into the tender. I recommend using an Exacto knife to raise the roller plate and pin the red power wire underneath the roller plate. The screws are not very long, so be careful not to turn the screw off the double nut/threaded post. (I had to remove the speaker baffle and the speakers to reach the double nut post and push it back in place so I could re-attach the pick-up roller.)

Note: When closing the tender, be sure to feed the smoke fluid fill pipe through the front of the tender first.

The engine ran nicely for over an hour as I worked to get the smoke units working again. The Niagara sat on display and the smoke units wanted to trip the ZWL breaker until I was able to add them one at a time. The Smoke Stack, Whistle Steam, Pop Off Valves, and Tender water vapor effect as the tender scoops up water, all draw a lot of power for the heating elements and fans.

This use of the Niagara tender water smoke effect and its corresponding "hissing/splashing" sounds from the sound system may have drained the YLB 10510 so that it let the tender drop sound. (As I typed the above sentence, I realized why the YLB would drop sound., the splashing sounds are broadcast the entire time the smoke is coming from the tender - longer than a normal whistle blow.)

Can a YLB fail after extended use? This battery is one of the 10 you dropped off at Henning's Trains this week. After using it for an hour, the sound would drop occasionally. I will run it without using the tender smoke and its sounds, especially over the switches. Not using the tender smoke long sustained sounds as often should greatly improve the performance.

Sincerely, John Rowlen

Attachments

John Rowlen posted:Gunrunner John,

I installed the second YLB 10510 in my Vision Line Niagara. The job took more time feeding the power wire through the tender floor and under the pick-up roller plate. I tried to wrap it around the pick-up roller screw, but had the nut fall back into the tender. I recommend using an Exacto knife to raise the roller plate and pin the red power wire underneath the roller plate. The screws are not very long, so be careful not to turn the screw off the double nut/threaded post. (I had to remove the speaker baffle and the speakers to reach the double nut post and push it back in place so I could re-attach the pick-up roller.)

Note: When closing the tender, be sure to feed the smoke fluid fill pipe through the front of the tender first.

The engine ran nicely for over an hour as I worked to get the smoke units working again. The Niagara sat on display and the smoke units wanted to trip the ZWL breaker until I was able to add them one at a time. The Smoke Stack, Whistle Steam, Pop Off Valves, and Tender water vapor effect as the tender scoops up water, all draw a lot of power for the heating elements and fans.

This use of the Niagara tender water smoke effect may have drained the YLB 10510 so that it let the tender drop sound after an hours use. (As I typed the above sentence, I realized why the YLB would drop sound. The tender smoke has to draw a lot of power as the tender goes over gaps in the switches, draining the YLB Battery.)

Can a YLB fail after extended use? This battery is one of the 10 you dropped off at Henning's Trains this week. After using it for an hour, the sound would drop occasionally, then more often. I will run it without using the tender smoke. Not using the tender smoke as often should greatly improve the performance.

Sincerely, John Rowlen

So the battery powers the smoke unit? I thought it only kept the sound on. ??

The YLB should last longer than most of us, and plugged into the sound board it isn't powering anything but the sounds. I'm not sure what is happening in your case, I'd start by checking to see if you lost the power connection.

Gunrunner John,

I apologize for my confusion. When the tender smoke is activated, there are "hissing/splashing" sounds that come from the tender. The sound board is generating those sounds at that time and getting support from the YLB. I run the tender sounds longer than I would blow the whistle. I will activate the tender away from the switches to help keep the battery fully charged.

The YLB has made it possible for me to bring out my Lionel steam engines and run them on my medium sized Atlas O layout, Thanks for the solution. The 10510 YLB will go in every steam engine to help them on Atlas O switches. I also have a double 90-degree cross-over that challenges the steam engine sound systems.

Sincerely, John Rowlen.

Interesting, I haven't really gotten to run my Niagara much, and it doesn't have a YLB yet.

The YLB obviously can't supply the duration of power that a battery would, but it manages to never need replacement, which is it's shining attribute. ![]() It's really intended to do what I stated previously, ride over dead spots in the track and for conventional operators to keep the sound going for direction changes. After a few no-power seconds of sound, it's ready for a charge again, that's all it's got. The major goal was not to have to keep taking stuff apart and replacing a leaking battery.

It's really intended to do what I stated previously, ride over dead spots in the track and for conventional operators to keep the sound going for direction changes. After a few no-power seconds of sound, it's ready for a charge again, that's all it's got. The major goal was not to have to keep taking stuff apart and replacing a leaking battery.

Guys, after all is said and done, Atlas is unjustly maligned. They did address the problem. Not sure if they solved it, since the effort of recovering a broken link in a 2013 OGR posting herein reffed regarding this has caused mental meltdown here. But being an Atlas member (only slightly expired) compels me to continue.

The broken link is "atlaso/manuals.htm". Now you will want " https://shop.atlasrr.com/t-manuals.aspx ". You will want possibly to click on "information" in the black band menu. Now you want to locate the manual for the #6924 non-derailing controller, by scrolling down (black type, denoting not a link). Below this heading is a fistful of links, colored blue. You will want "POWER ROUTING USC.copy.pdf" as a download from/thru this link "Powering Closure Rails". (I exactly cannot recall and am leaving this window to check if I've given enough info--and am not sure if I can get back--my laptop is RAM-short and often cannot respond as now.) Frank

PS-- You must install "anti-derailing". More reading here for you.

The Atlas O 6924 Non-Derailing board was out-of-production for a while. Is it back in stock? Or like their Dwarf Signals, out-of-stock and hard to find anywhere. That they have a solution is only good, if they have the item available for sale.

Thank you for the information. I was able to find some of the 6924 boards five years ago when I started my "Valley of Bridges" Atlas O Century Track Layout. I still have to wire my switches. One-quarter of the road signals are installed.

Sincerely, John Rowlen

I just went to Atlas O website and located the 6924 Non-Derailing Board for $28.95 each. I place the number 10 in the cart and the website said they have "0". The item is backordered. Glad I bought some five years ago.

Here is Atlas O's solution, but they don't have any.

I am not trying to beat up Atlas O. I love my 600 Atlas O Master Line cars. I probably should sell some and re-claim an upstairs bedroom.

Terry Christopher emailed me that Atlas O will be taking over his Custom Signals when he retires. Hopefully these beautiful signals will be available for other railroaders. Again, I am glad I bought all styles of Signals and many of the connector cables to allow the signals to talk to each other. I just have to get down to my "Valley of Bridges" layout and finish it.

Sincerely, John Rowlen

You have hit on the reason I'm going with Ross switches and Gargraves track. I can get any and all of it when I need it. ![]()

I visited Mr Muffins layout (and Choo Choo Café and Store) last weekend and wondered what kind of track he used. It looked very nice...no plastic roadbed...I think wooden ties or at least they looked good like wood. I don't remember looking at any switches. There were a half dozen trains running and there was minimal noise. Very nice. Smooth running and prototypical speed it seemed.

I really like to look under the layout at the wiring more than on top sometimes ![]()

cjack posted:I visited Mr Muffins layout (and Choo Choo Café and Store) last weekend and wondered what kind of track he used. It looked very nice...no plastic roadbed...I think wooden ties or at least they looked good like wood. I don't remember looking at any switches. There were a half dozen trains running and there was minimal noise. Very nice. Smooth running and prototypical speed it seemed.

I really like to look under the layout at the wiring more than on top sometimes

IIRC they have Atlas track.

Looks like Atlas track to me in their videos.

Yes, those ties are plastic. ![]()

Attachments

gunrunnerjohn posted:You have hit on the reason I'm going with Ross switches and Gargraves track. I can get any and all of it when I need it.

In this day and age of importers seemingly having little control over the foreign made products they sell under their own brand name, availability can become a very important selling point. Back when Atlas' N scale code 55 track had made such an impact on that scale, the fact that it then became unavailable for a long time was a real problem for those who had committed to using it.

Also, interesting that the above mentioned track products are both made in the US... ![]()

Mark in Oregon

Strummer posted:Also, interesting that the above mentioned track products are both made in the US...

BINGO!

gunrunnerjohn posted:Looks like Atlas track to me in their videos.

Yes, those ties are plastic.

Ah so...Which Gargraves are you considering? I kind of like the blackened center rail. Don't know how that would wear. Stainless or tin plated? Lots of choices.

I'm using the standard tin plated with the blackened center rail, the "cheap" flex track. I have a case of it, and I suspect I may need another with the expansion I'm working on. ![]()

I like my Atlas O Century three-rail track. Despite the switch gaps, which Gunrunner John's YLB 10510 solves, The track has held up nicely for five years.

The ties are UV Protected plastic. There is no connector bridge between the outside rails, so creating insulated/isolated rail sections to trigger Atlas O Road Signals is easy. I just add a power connector to both outside rails. No problem.

The Atlas O Pratt bridges and Girder bridges are amazing and handle the heaviest of my steam engines. That is why my layout is called "Valley of Bridges".

I really need to get to the basement and finish that layout. I am spending more time running trains.

Sincerely, John Rowlen

The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku. The Big Boy tender already has a wide roller spacing, so it doesn't have the issue on the Atlas #5 switch. I've now had the Challenger design revised to open the roller spacing so it won't have this issue when the Big Boy ships.

Thanks for pointing this out. As mentioned here previously, we cannot design for every other manufacturer's track system, but I will always be open to these comments so that designs are modified to try to keep everyone happy. ![]()

Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku.

Aside from the difference in roller spacing, the "Challenger tender" should be the oil burning type, as currently used ONLY on #4014 as restored (remember that the tender from #3985 is currently attached to #4014). The "Big Boy tender" would be the coal burning version, which begs the question, will the model of the engine be a coal burning versions with ash pans and ash hopper?

The Big Boy tender already has a wide roller spacing, so it doesn't have the issue on the Atlas #5 switch. I've now had the Challenger design revised to open the roller spacing so it won't have this issue when the Big Boy ships.

Thanks for pointing this out. As mentioned here previously, we cannot design for every other manufacturer's track system, but I will always be open to these comments so that designs are modified to try to keep everyone happy.

Hot Water posted:Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku.

Aside from the difference in roller spacing, the "Challenger tender" should be the oil burning type, as currently used ONLY on #4014 as restored (remember that the tender from #3985 is currently attached to #4014). The "Big Boy tender" would be the coal burning version, which begs the question, will the model of the engine be a coal burning versions with ash pans and ash hopper?

We're making new tooling so that the Big Boy tender will be the oil type and the refueling dialog will reflect that as well.

Dave Olson posted:Hot Water posted:Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku.

Aside from the difference in roller spacing, the "Challenger tender" should be the oil burning type, as currently used ONLY on #4014 as restored (remember that the tender from #3985 is currently attached to #4014). The "Big Boy tender" would be the coal burning version, which begs the question, will the model of the engine be a coal burning versions with ash pans and ash hopper?

We're making new tooling so that the Big Boy tender will be the oil type and the refueling dialog will reflect that as well.

Very interesting. However, currently #4014 does NOT have/use her original "coal burning" tender, since that tender has NOT been rebuilt nor converted to "oil burning", and with future budgetary constraints on UP, it is doubtful whether 4014s original tender will ever be rebuilt/converted to oil. Thus, #4014 will continue to operate with the converted to oil tender from Challenger #3985.

cjack posted:gunrunnerjohn posted:Looks like Atlas track to me in their videos.

Yes, those ties are plastic.

Ah so...Which Gargraves are you considering? I kind of like the blackened center rail. Don't know how that would wear. Stainless or tin plated? Lots of choices.

I run my trains every day and have never had the blackened gargraves rail become un- blackened. I’ve seen every other brand except Ross loose the black coating. I don’t know what the Gargraves secret is but it’s definitely superior to anything else on the market.

Dave Olsen, (and Lionel)

Thank you, Thank you, Thank you. Thank you for listening to buyer's input. The increased space between pick-up rollers is an excellent move on the new Big Boy Oil Burning Tender.

You made me smile today. We both know how hard that is to do. You are my hero. Get Tacos and celebrate.

Sincerely, John Rowlen

Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku. The Big Boy tender already has a wide roller spacing, so it doesn't have the issue on the Atlas #5 switch. I've now had the Challenger design revised to open the roller spacing so it won't have this issue when the Big Boy ships.

That's great Dave, but you're cutting into my YLB sales. ![]()

Lionel should be commended for changing a tender design to fix a problem created by another switch manufacturer. Yes, I know Lionel should have never changed the original design but at least they stepped up and are willing to make it right. How bout the switch manufacturer?

gunrunnerjohn posted:Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku. The Big Boy tender already has a wide roller spacing, so it doesn't have the issue on the Atlas #5 switch. I've now had the Challenger design revised to open the roller spacing so it won't have this issue when the Big Boy ships.

That's great Dave, but you're cutting into my YLB sales.

John,

There are so many locomotives out there with this issue either because of pick-ups or common rail loss your sales are only guaranteed to increase! (the real issue of course is the sounds don't automatically restart;-)

John Rowlen posted:I just went to Atlas O website and located the 6924 Non-Derailing Board for $28.95 each. I place the number 10 in the cart and the website said they have "0". The item is backordered. Glad I bought some five years ago.

You are probably way ahead of me on all this, but along with their new signal system, I thought Atlas was also redesigning the 6924 boards? However, upon looking at their website, I found the new signal system, but no sign of a new 6924, only the old one that is out of stock and backordered. So I came up short on that thought.

Bringing back dropped or softer sounds

I switch the engine's ID to another Engine ID and back to the original ID on my 990 Remote, and that will usually bring the sounds back to full volume on the engine that drop some of its sound. I do not know why it works, but it does.

Gunrunner John's YLB 10510 Battery will still be used on all 46 Lionel Steam Engines, excepted the tethered steam engines. Tender rollers are the main issue on Atlas O track. The diesels have a larger footprint to travel over switches better.

Sincerely, John Rowlen

RTR12,

Give Atlas O some time to get the product pipeline filled. The announcement about the Custom Signals was made within the last 30 days. That Atlas is working on the signals is very positive news.

Here are some pictures of my Double Cross-over Interlock Signals and the approach to it. Some signals are connected with Atlas O cables and communicate to each other, while others farther away are set for automatic timing. Two Road Signals are also shown. At the Interlock, I placed the signals where they are to avoid the #4014 VL Big Boy from knocking them over. Sometimes the Fireman has to relay signals on close/obstructed view track.

Sincerely, John Rowlen

Attachments

rtr12 posted:John Rowlen posted:I just went to Atlas O website and located the 6924 Non-Derailing Board for $28.95 each. I place the number 10 in the cart and the website said they have "0". The item is backordered. Glad I bought some five years ago.

You are probably way ahead of me on all this, but along with their new signal system, I thought Atlas was also redesigning the 6924 boards? However, upon looking at their website, I found the new signal system, but no sign of a new 6924, only the old one that is out of stock and backordered. So I came up short on that thought.

I was trying to add the 6924 boards to a pair of new Atlas switches last winter. I reached out to Atlas and received a very prompt email that the 6924 boards were gone and would not be restocked in the future. Maybe something has changed since then. My solution was to swap the Atlas switch motors out for Z1000s which have built-in anti-derail capability and cost about the same as the 6924 boards.

Rider Sandman posted:rtr12 posted:John Rowlen posted:I just went to Atlas O website and located the 6924 Non-Derailing Board for $28.95 each. I place the number 10 in the cart and the website said they have "0". The item is backordered. Glad I bought some five years ago.

You are probably way ahead of me on all this, but along with their new signal system, I thought Atlas was also redesigning the 6924 boards? However, upon looking at their website, I found the new signal system, but no sign of a new 6924, only the old one that is out of stock and backordered. So I came up short on that thought.

I was trying to add the 6924 boards to a pair of new Atlas switches last winter. I reached out to Atlas and received a very prompt email that the 6924 boards were gone and would not be restocked in the future. Maybe something has changed since then. My solution was to swap the Atlas switch motors out for Z1000s which have built-in anti-derail capability and cost about the same as the 6924 boards.

DZ1000 switch motors require the additional DZ1008 latching relay to do power routing. There is also non-derail wiring required. Wiring information available on both the DZ and Ross websites.

Click on the triangle for a video of switch operation with both non-derail and power routing. This Fort Pitt Highrailer layout "Y" module was done with Ross Switches and DZ1000 switch motors. The DZ 1008 latching relays were added for power routing. There is dual control switching done with a Lionel SC-2 switch module parallel wired to each switch motor.

Slideshow of the module build and wiring. Click on the underlined phrase.

Turntable and associated spur tracks/roundhouse tracks are Atlas. TT is custom, using Diamond Scale components and design.

John Rowlen posted:RTR12,

Give Atlas O some time to get the product pipeline filled. The announcement about the Custom Signals was made within the last 30 days. That Atlas is working on the signals is very positive news.

Here are some pictures of my Double Cross-over Interlock Signals and the approach to it. Some signals are connected with Atlas O cables and communicate to each other, while others farther away are set for automatic timing. Two Road Signals are also shown. At the Interlock, I placed the signals where they are to avoid the #4014 VL Big Boy from knocking them over. Sometimes the Fireman has to relay signals on close/obstructed view track.

Sincerely, John Rowlen

I am a big fan of the Atlas signal system and have been following the development of their new system. Atlas and Custom Signals worked together on the previous Atlas 21st Century signal system, so it seems logical for them to take over Custom Signals. I was sure hoping someone would take over for Custom Signals. Atlas will be a good fit here. (Or Custom Signals will be a good fit here too.)

Your signals look very nice, as does your layout. I am hoping someday to expand my layout and also add some Atlas signals to it. I really want to do all the interlocking and try to take advantage of the full capabilities of the system as best as I can.

Rider Sandman posted:rtr12 posted:John Rowlen posted:I just went to Atlas O website and located the 6924 Non-Derailing Board for $28.95 each. I place the number 10 in the cart and the website said they have "0". The item is backordered. Glad I bought some five years ago.

You are probably way ahead of me on all this, but along with their new signal system, I thought Atlas was also redesigning the 6924 boards? However, upon looking at their website, I found the new signal system, but no sign of a new 6924, only the old one that is out of stock and backordered. So I came up short on that thought.

I was trying to add the 6924 boards to a pair of new Atlas switches last winter. I reached out to Atlas and received a very prompt email that the 6924 boards were gone and would not be restocked in the future. Maybe something has changed since then. My solution was to swap the Atlas switch motors out for Z1000s which have built-in anti-derail capability and cost about the same as the 6924 boards.

It is my understanding that the 6924 boards have been discontinued and will be replaced by an improved version that will be better compatible with their new signal system. I know these have been unavailable for sometime now, but as John said above, give them some time and we may see an even better product available in the future.

Oops, forgot the DZ1000 part. I am using one of those too and they are very nice. That is a very good product and works very well too.

I originally experienced a stalling issue with an Atlas 0-80 curved switch back in 2002. Looking at where the locomotive lost power I was able to determine increasing the length of the center rail by less than a ¼” would allow the locomotive through without a problem.

So initially I tried soldering a piece of copper to the center rail where it meets the “V” shaped piece of plastic, however, I soon realized this would not work as I was unable to get the solder to stick,

The next thing I did was to form a small piece of aluminum foil over part of the center rail extending it slightly over the plastic piece and found this worked fine. The locomotive passed through without issue. Unfortunately, the foil would ware out quickly.

Later while attending a train show in Edison N.J. where Atlas had a set up, I spoke with a representative regarding this and a bunch of other Atlas switch issues. He informed me that Atlas was working on a solution that involved small extensions that would snap on over the center rail and lengthen it slightly to alleviate the stalling. This of course never happened. Instead Atlas released the non-derailing board some 5 or so years later.

It is now some 17 years later, and this problem still exists. I no longer have any Atlas switches on my layout having switched all 25 of them out for Ross. Between the stalling issues and over time the loss of power through the switch along with switch machines that would go bad even if never used, I gave up on Atlas switches. However, the track itself is very nice and works well with Ross products.

Since switching to Ross I’ve had no switch related issues. There’s no need to power the switch on all three sides to guard against losing power through it. No need to purchase additional non-derailing boards (which by the way are no longer available) or new momentary switch actuators to prevent switch machine burn out (these devices are also no longer available).

And best of all there made in the USA and cost less. Plus Ross stands behind there products 100%.

Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku. The Big Boy tender already has a wide roller spacing, so it doesn't have the issue on the Atlas #5 switch. I've now had the Challenger design revised to open the roller spacing so it won't have this issue when the Big Boy ships.

First, let me say I appreciate Lionel considering making a change to the roller spacing. In regards to the different tenders, let me preface my remarks by saying I am NOT an expert on steam tenders. As I read the data shown on UtahRails, the tender that went with UP 4014 to CA was apparently the tender that originally belong to UP 4015. It was a Class 25-C tender. From thetable on the website, it seems that the late model coal and oil burning Challengers used the same class of tender. UP 844's tender looks to be a Class 23-C (oil). The numbers seem to be water capacity in 1000's of gallons. If their data is correct, maybe there was a Big Boy/late model Challenger tender and an FEF-3 tender. The tender Lionel produced with the last run of FEF-3 has a wide roller spacing and looks like the tender pictured in the Vol2 catalog art for the excursion model. However, maybe Lionel only needs the same class 25-C tender (oil) for both versions of the Big Boy. Of course, since 4014's tender hasn't been converted to oil it is hard to know what it will eventually look like. Hopefully, people on this forum who know more about steam engines can correct any information I found on UtahRails.

Thanks again for thinking about changes in the roller spacings.

John Cullen

Dave Olson posted:The newest Big Boy will come with either the Big Boy tender or the Challenger tender depending on sku. The Big Boy tender already has a wide roller spacing, so it doesn't have the issue on the Atlas #5 switch. I've now had the Challenger design revised to open the roller spacing so it won't have this issue when the Big Boy ships.

Thanks for pointing this out. As mentioned here previously, we cannot design for every other manufacturer's track system, but I will always be open to these comments so that designs are modified to try to keep everyone happy.

Now this is great and how should be when something is wrong. Honest open and stating outright the problem will be fixed and making sure everyone knows. Cudos on Lionel on this.

Gunrunner John,

I just ordered four of the 10500 original Battery Clip YLB Batteries with the 9-volt battery clip. I opened my 6-11210 1st run Vision Line Challenger tender and discovered it had the 9-volt clip, but on a different style plug than the 10510 new YLB Batteries I bought. Murphy's Law got me again.

It looks I will have to buy a supply of both the 10500 and 10510 as I put the YLB Battery in all of my steam engines. I bought three 10500 a while back, but they are buried somewhere in my "VERTCAL PILING SYSTEM". I am digging through the piles, but the ones I ordered today will probably arrive before I find those that are buried.

Sincerely, John Rowlen

I found two sealed 10500 in my "Vertical Piling System" along with several Lionel Legacy Engine Manuals. I will put the YLB in the 6-11210 Challenger #3967 and then break for dinner before doing the Allegheny.

The YLB battery is a big help.

Sincerely, John Rowlen

Dave Olson, thanks for doing the redesign. But, roller spacing has been a known problem for years now so somehow this knowledge was forgotten when the original design was approved.

Gunrunner John,

I put the YLB 10500 Battery with traditional 9-volt Battery Clip fitting in my 6-11210 Challenger and the 6-82768 Allegheny #1604. The Niagara #6013 took the YLB 10510 with the sound board plug.

The YLB Batteries have eliminated the sound going off as my Lionel engines go over Atlas O #5 switches. The battery quickly charges and provides 5 seconds of support power to the sound board.

I bought the last six YLB 10500 and three more 10510 that Henning's Trains had today, Tuesday, August 20th. You have five 10510 left with the sound board plug. The other four 10500 I bought Saturday, are still currently in the mail.

I included a video of the Vision Line Challenger #3967 and Allegheny #1604. Both are articulated engines.

Sincerely, John Rowlen

Attachments

One thing I will say, it would be nice to develop some standards in "O" gauge as "HO" has done.

Just MHO ![]()

NYC 428 posted:One thing I will say, it would be nice to develop some standards in "O" gauge as "HO" has done.

Just MHO

Boy,,,,,,talk about an EXCELLENT suggestion!!!!! However, none of the 3-Rail manufacturers seem to give a crap about NMRA "standards" for O Scale, i.e. 1/4" to the foot. They can't even produce the same locomotive model from one year to the next with the same features/sound, such as the Lionel Vision line Challengers.

NYC 428 posted:One thing I will say, it would be nice to develop some standards in "O" gauge as "HO" has done.

Just MHO

I think I mentioned something along those lines back on the first page of this discussion... ![]()

Mark in Oregon

It just makes no sense having no standards in O gauge. Now so more than ever. Lionel , MTH, Atlas and Bacman make HO which they have to make to standards. Oh I guess someone would have to set the standards. If and when it is ever done it would be better for everyone.

Too late for standards now. If I could sell everything and start over I’d go with 2 rail O. My mistake from the beginning when I went to Ogauge in the mid 80’s.

STRUMMER, what can I say great minds think alike

John Rowlen posted:I bought the last six YLB 10500 and three more 10510 that Henning's Trains had today, Tuesday, August 20th. You have five 10510 left with the sound board plug. The other four 10500 I bought Saturday, are still currently in the mail.

All restocked today John, go buy some more! ![]() They're not on the web page yet, but I dropped off ten of each type this afternoon, so I know they have them.

They're not on the web page yet, but I dropped off ten of each type this afternoon, so I know they have them.

In an effort to stop the sound drop-out of my Lionel steam engines, I installed twenty-six YLB Batteries in the first third of my steam engines. The engines are running perfectly now over switches that in the past would interrupt the sound.