@Chuck, I am sure many of us are amazed at 1/4 peg board plus carpet. How do you screw things down?

PS, You must grin at the threads extolling 2x4s and 3/4 plywood. ![]()

|

|

@Chuck, I am sure many of us are amazed at 1/4 peg board plus carpet. How do you screw things down?

PS, You must grin at the threads extolling 2x4s and 3/4 plywood. ![]()

I put a flat head screw, occasionally, in the pegboard joints that rest over the Sievers Benchwork 1 X 4s. It’s slightly flexible when I walked on it but quite strong. The Sievers has 1 foot centers.

It all developed when I found all the plywood at Home Depot so wavy and some downright warped. The 1/4 pegboard was nice and flat. Actually I think it’s 3/16 and at Lowe’s and Menards it was 1/4, but basically the same.

I just measured my access holes, they are actually 1 foot by 3 feet, I was guessing 2 by 4 and got to thinking when I remembered that the Sievers had 1 foot centers on the benchwork. I guess that's why I have to duck down to turn around. My hip bones are farther apart than a foot. ![]() But with a small foot stool under the layout I can easily climb up out of the hole if I want.

But with a small foot stool under the layout I can easily climb up out of the hole if I want.

So it all works for me...I love being able to poke an awl into the carpet and find a hole to run the power for things thru. I noticed in my picture that sometimes I didn't go under the switch which is a bit constrained and found the nearest hole just outside. But the grey covering on the 4 conductor cable blends in with the grey carpet...thought about green, but grey blended better with the track.

Slow and not so steady, but I'm making some progress. I got my Ross switches and Gargraves track in, and I just picked up my wood for the top. I went with 5 x 5 birch multi-ply, it's really nice and flat and will make getting it together a lot easier than the cheaper plywood. It also helps with the Mianne spacing, my 4 foot wide bench actually needs 49 3/4" to go to the outer edges of the legs. This would be a giant PITA with 4 x 8 sheets.

GRJ-

those birch multi- ply sheets of 60” x 60” will be really solid now and over the years! No warping I’m sure!

Carl J

I'm going to hate to cover it with track and scenery, it's such pretty wood. ![]()

Right, that's nice stuff GRJ, too bad it'll be covered with scenery and ballast! ![]() I've done a little cabinetry with that material and it looks great with a stain and finish--and super flat it certainly is.

I've done a little cabinetry with that material and it looks great with a stain and finish--and super flat it certainly is.

I didn't realize it was so inexpensive, I expected nice panels like this to cost more. ![]()

GRJ, Which thickness did you go with?

Tom, I cheaped out and used 1/2". Handling 3/4" by myself is pretty heavy, I hefted a sheet of each and decided on the 1/2". ![]()

gunrunnerjohn posted:Tom, I cheaped out and used 1/2". Handling 3/4" by myself is pretty heavy, I hefted a sheet of each and decided on the 1/2".

Had to laugh as I was thinking about myself as I read this. As I age I want and NEED Lighter materials. It is not cheap just age for me!

Well, it was 80% age for me as well. If the 3/4" panels were easy enough to handle by myself, I'd have gone that way. I wasn't that concerned about the difference in price, I only have a 12.5 x 20 layout.

gunrunnerjohn posted:Slow and not so steady, but I'm making some progress. I got my Ross switches and Gargraves track in, and I just picked up my wood for the top. I went with 5 x 5 birch multi-ply, it's really nice and flat and will make getting it together a lot easier than the cheaper plywood. It also helps with the Mianne spacing, my 4 foot wide bench actually needs 49 3/4" to go to the outer edges of the legs. This would be a giant PITA with 4 x 8 sheets.

Where does on buy 5x5 sheets of plywood. Did this come from a big box store, or did you need to go to a lumber yard?

You have to go to a lumber yard, and for this I went to a place in Reading PA, Russell Plywood. They specialize in plywood and had several hundred sheets of this in stock. Cool stuff, it has 9 plies as opposed to standard 1/2" plywood with three.

gunrunnerjohn posted:Slow and not so steady, but I'm making some progress. I got my Ross switches and Gargraves track in, and I just picked up my wood for the top. I went with 5 x 5 birch multi-ply, it's really nice and flat and will make getting it together a lot easier than the cheaper plywood. It also helps with the Mianne spacing, my 4 foot wide bench actually needs 49 3/4" to go to the outer edges of the legs. This would be a giant PITA with 4 x 8 sheets.

Have gone to using Baltic Birch for everything I can John. A lumber yard near here had the 5' X 5' as well as 4' X 8' in different thicknesses.

That looks nice! I think you will be just fine with the 1/2". Not Baltic birch, but I did the same thing with 1/2" due to weight of 3/4". Even had Home Depot cut the 1/2" sheets to size before trying to load them up. I got Sandply (7 plies) which is (or was) also pretty good stuff, flat and smooth and no voids in the plies.

All the 'real' lumber yards here have turned into Home Depot or Lowes. I have not yet checked with Menards, they have opened a few stores in this area over the last few years. Menards does seem to have a better selection than the others when it comes to different lumber types.

Also, wish I would have done like you are and extended the plywood out to the edge of my Mianne legs. Maybe even a little past the edges.

My plan is a fascia on the outside of the legs, and I want the table surface to come up to the fascia. Still cogitating on any extra surface on the plywood, I might go with some thin hemosite on the surface, but I'm up in the air about that. First things first, get the basic top on after some pre-wiring.

I looked at the sandply, but the 5 x 5 sheets were perfect for my situation. It really wasn't much more for the birch.

That really is some nice birch.

John that looks and sounds like furniture grade plywood could be that place was selling waste or surplus to get that high quality at a bargain price. Good job finding it.

I don't think so, they're a wholesale plywood company, it's their business. Russell Plywood - Home. When I asked before going up, they had 200+ sheets in stock, and they stated this was a stock item that they normally always have on hand. I have a contractor friend that uses them, that's how I found out about them. None of the local stores or lumber yards carried the right size.

It certainly looks like furniture grade, one side is a perfect wood grain. The other side is also smooth without voids, but it has the oval patches in places. It really is great looking wood, seems a shame to use it on the layout. OTOH, I know where to get more at a good price if I ever have a different project. ![]()

That's nice stuff John. Perfect for going a little over 4'. With the Mainne base the 1/2" should be fine.

Now if it was me I would have put a loop of track on that pile and ran a train....but that's just me ![]()

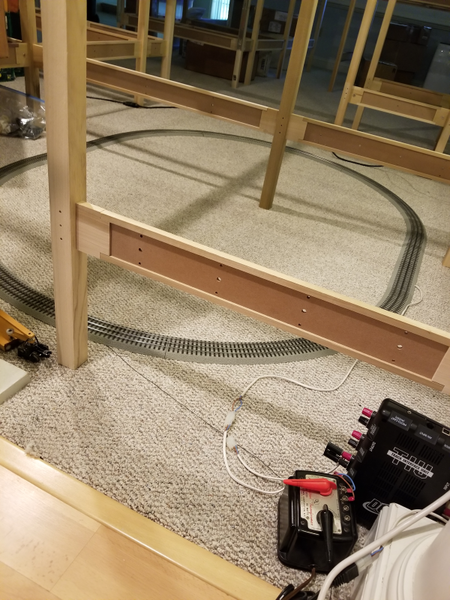

Well, I tried to put a loop on the benchwork, but it fell through. ![]()

![]()

I guess you need the birch ply there to stop it from falling like that. I hate when that happens.

gunrunnerjohn posted:Well, I tried to put a loop on the benchwork, but it fell through.

Oh, the humanity!!!

Lol John, every new RR begins one track at a time!!

This one has just been a long time coming. However, we're slowly moving in the right direction. ![]()

John, I am glad to see your Dream Layout is progressing along. Your certainly buying quality building materials which is the right way to go, I do recommend Homasote for the sound deadening and ease of screwing the track to just the Homasote. It’s fun, when you get to the point of running your trains, to sometimes simply turn off all sounds and listen to the trains run Quietly with just the clickety clack of the wheels going over the rails.....I have noticed over the years that each engine, whether it be Lionel, Atlas O, Sunset 3rd Rail, MTH, ETC., HAVE their own unique situations on the track and turnouts. If your running Big Boys, or 0-4-0’s, or 4-8-4’s, Whatever, the Front End swing, or the rear end swing, it’s all in the Game.

Thanks for the updates, looking forward to more.....Happy Railroading

Larry, if you lay homesite on top of plywood don’t the screws engage the plywood? Does this cause the plywood to resonate ?

Homosote

Homasote.

You glue it to the plywood and use 3/8” screws to secure the track to the...

1/2” homasote.

If you are using homasote, you really don’t need expensive cabinet grade birch plywood, but it certainly doesn’t hurt. Not my call. Just sayin.

Just build it man. Have fun.

.

I have built a lot os layouts over the last 70 years. Always used 1/2 inch plywood. Never a problem.

The reason for the multi-ply was simple, it's much flatter than the standard plywood generally available. Also, since a lot of my layout is going slightly over four feet wide, 4x8 sheets are very wasteful. The difference in the price of plywood and the multi-ply wasn't all that great, especially considering the multi-ply came in the 5x5 sheets that work out more efficiently for this particular layout.

Another reason for better wood is the Mianne benchwork only has attachment to the plywood at the legs, so the possibility of warping later is much greater with fewer layers in the plywood, this stuff has nine layers and is much less likely to warp over time. I've already spent around $4000 on all the track, switches, benchwork, wire, and roadbed. Less than $100 extra for better wood seems like a really good investment.

I've run on layouts like that, some of them mine, so I'm trying to do better this time. ![]()

Ok, everyone has great ideas, I used 5/8, 5 ply plywood, 5/8 homasote, and 1/4 inch cork roadbed, and used Atlas O screws to fasten the track to the homasote. They do not penetrate The plywood. Atlas O and Ross track. Also, one very important suggestion, when laying the track, I highly recommend leveling the track. Homasote is wavy and another thought is to paint it a good color of your choice. We used dark green and dark brown. This helps keep the moisture out. My layout is located in my basement, so far, no moisture issues. We do have a 16 seer Trane system for our middle level and the basement.

If I have looked at the pictures correctly, the layout Benchwork is made of excellent materials, and rests on nice carpet. I am not sure homasote is necessary if cork roadbed is under the track. My thinking was in the olden days, tubular Track fastened to plywood laying on saw horses, running TinPlate toy trains caused vibration issues. Happy Railroading

John:

The multi-ply is the right way to go for exactly the reasons you state. It’s one thing I’ve sworn to use if I ever build another layout. When I built my layout I was extremely careful to get the flat parts perfectly flat. After 12 years there are a couple wavy spots that can only have resulted from wood movement. My basement is extremely dry, so I’m sure this hasn’t been caused by dampness and the room is also heated and air conditioned, so temperature swings aren’t an issue either. An additional benefit, I believe, is that the rigidity and stability of the multi ply might help a little to dampen vibration and be a little quieter.

The “wavy” areas on my layout are very subtle and I doubt anyone but me has noticed. I actually like the minute rocking of freight cars traversing this section caused by the plywood warping slightly, passenger trains, not so much.

I sure wish we lived closer together, I’d love to be helping with your construction.

I wish you lived closer too Pat, because you'd be a real asset in putting this together! I've seen your woodworking, and it would be a think of beauty with your hands in the mix! The jury is still out what it'll look like after I get through with it. ![]()

As for vibration, since the Mianne benchwork only attaches in a few places, I'm seriously considering running a bead of construction adhesive along all the beams to prevent them from vibrating against the beams, I suspect that could be a major source of vibration and noise. My other thought was some thin rubber sealing strips along the beams to keep them from vibrating against the beams. They would have the benefit of not being permanent if I had to pick a piece of the plywood up.

Although I'm really Jonesing to have a layout to run on, I'm glad I took my time as I've made several changes after reflection on where it was headed. If I had charged ahead with the first concept, I don't think I'd have been as happy with the end result.

John, have you considered sill sealer to place between the base and plywood? It comes in rolls at the box stores, can be doubled if desired and if compressed between the plywood and beams, will stop vibration and be easy to separate if work on it later.

I wasn't sure what it was called, that's what I'm thinking about. It's about 3/8" wide and maybe 1/8" to 1/4" thick, and indeed comes in rolls. I have some, but it's not in it's package, so I was just going to go look for it in Lowes. ![]()

Access to this requires an OGR Forum Supporting Membership