Howdy Train Folk!

It’s Eli from Flint Rock Valley.

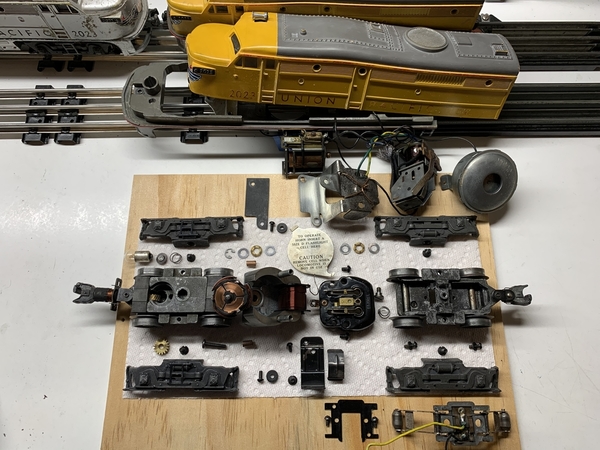

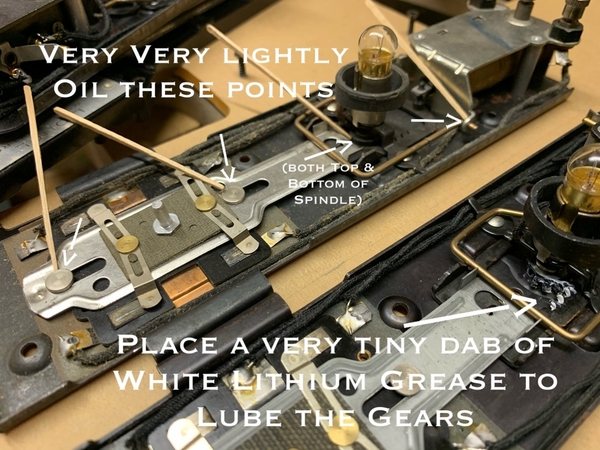

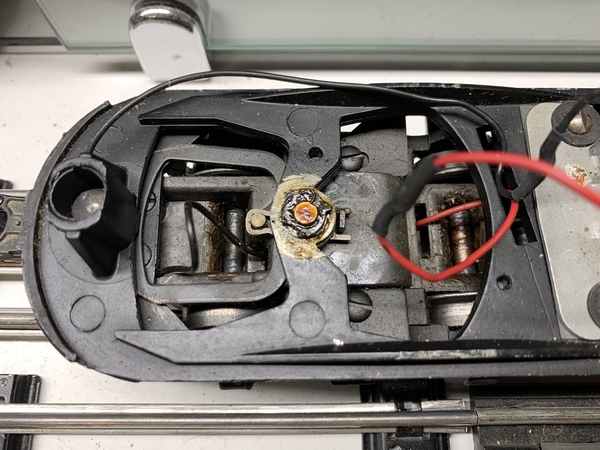

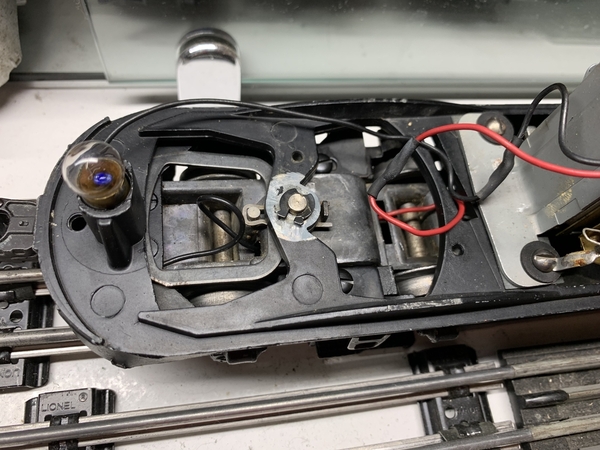

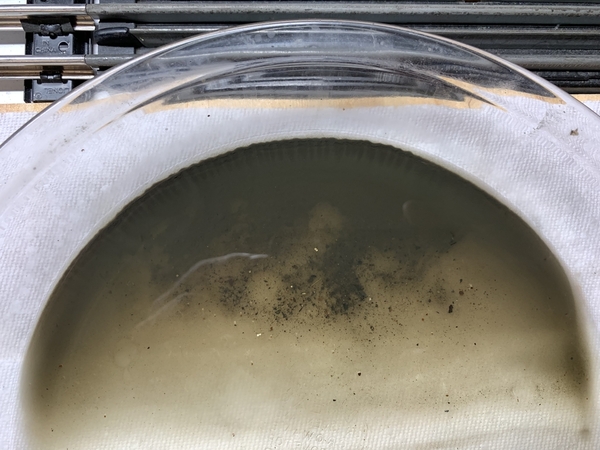

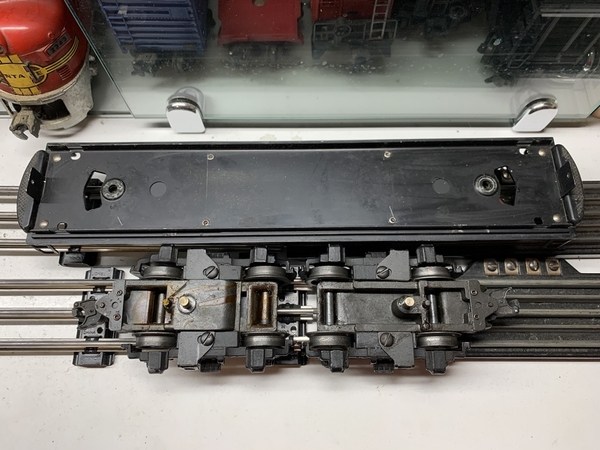

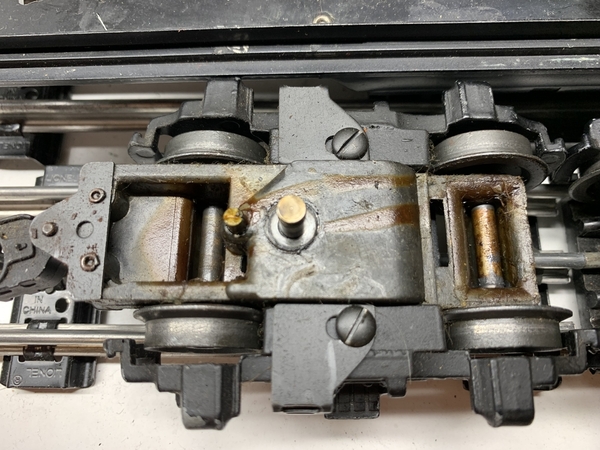

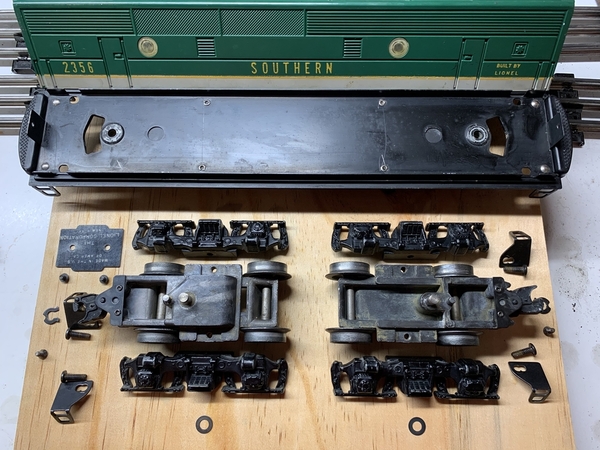

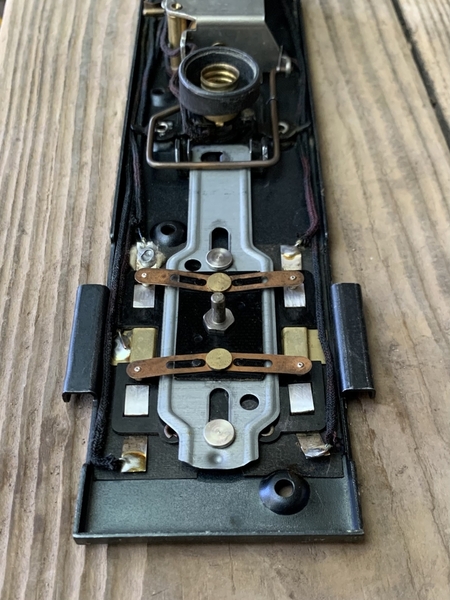

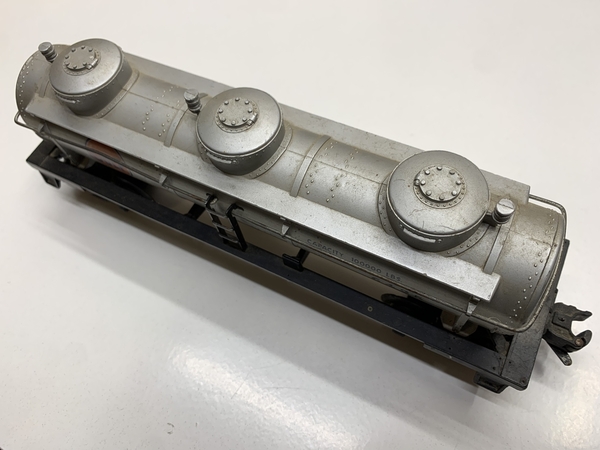

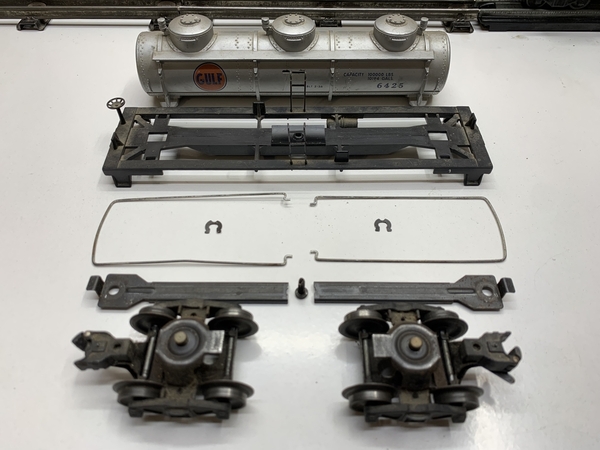

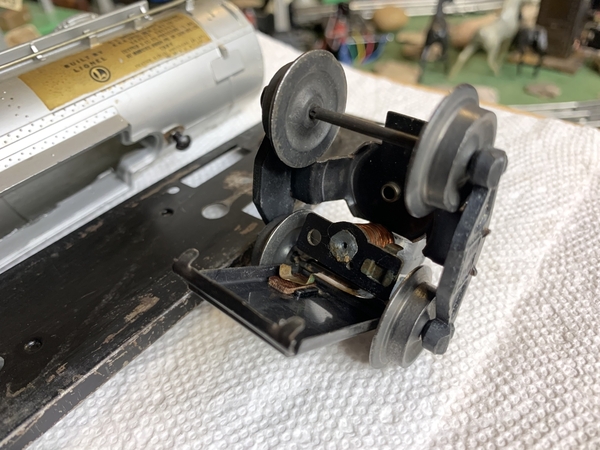

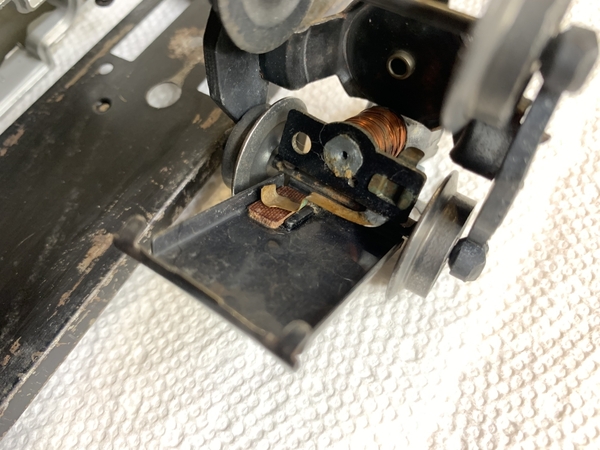

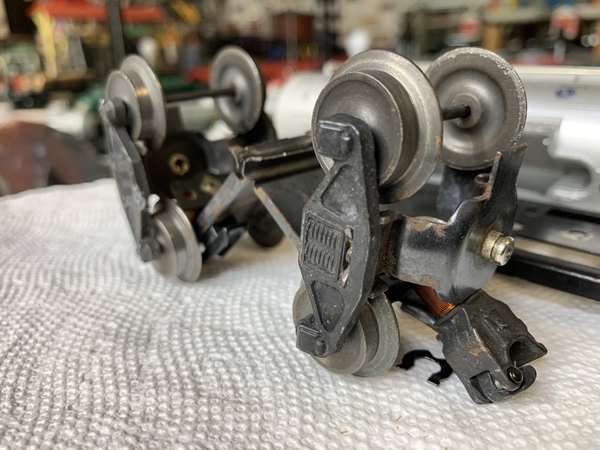

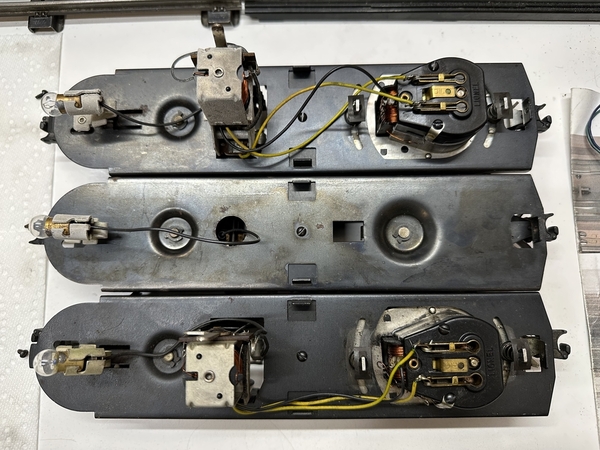

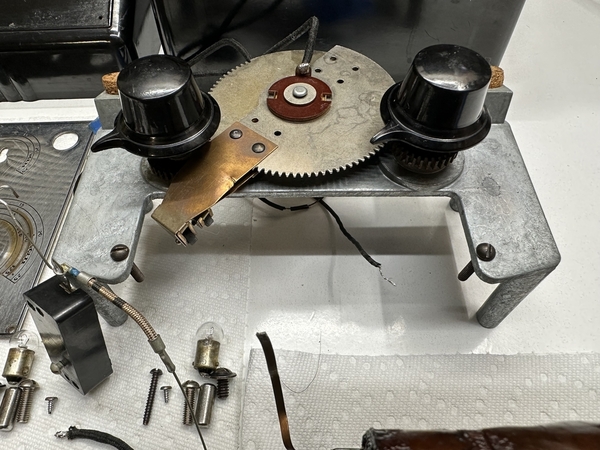

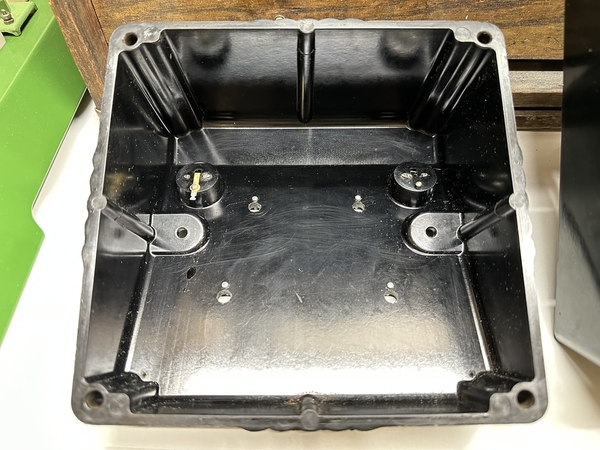

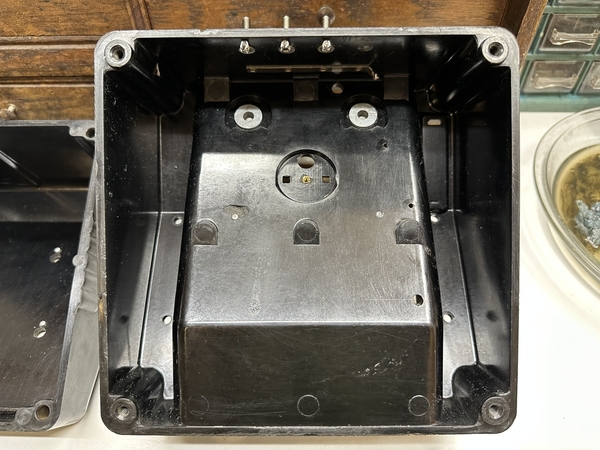

I have been repairing & rebuilding my Postwar Lionel Trains for quite sometime now. After a long hiatus & working on my Control Panel & finishing touches on my layout I can now get back to my Service Yard/ Desk. Not one single engine, rolling stock, or otherwise gets put on the layout without a thorough going through. Whether it be a simple cleaning, & or an entire breakdown & rebuild. And from this point forward I shall document the process to share w/ you.

Due to the lengths of my clips you’ll have to view them via my channel. Hopefully they will be of some help to those in need.

As always I welcome any & all comments & questions.

Hope Y’all enjoy the view...

& Thanks so much for “Tuning” in!