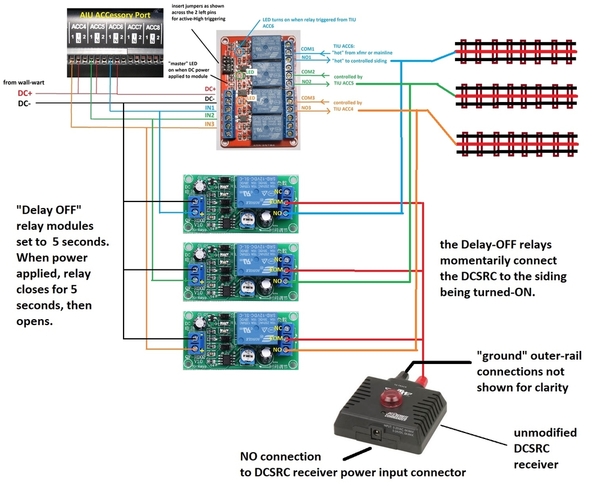

This is a classic case of measure-twice, cut-once. That is, if you sketch out your relay wiring ahead of time you can skip the wiring clutter that is the inevitable consequence of an ad hoc wiring-as-you-go approach. Here's a crude sketch illustrating a few ideas to consider (pic should be click-able to expand):

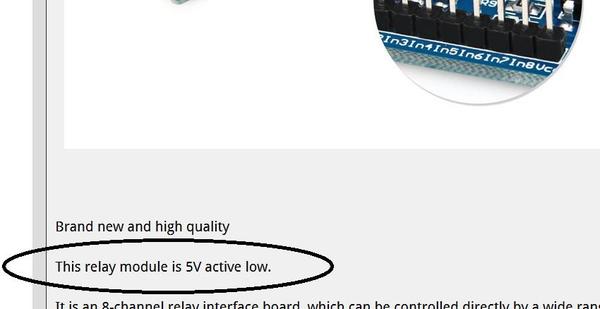

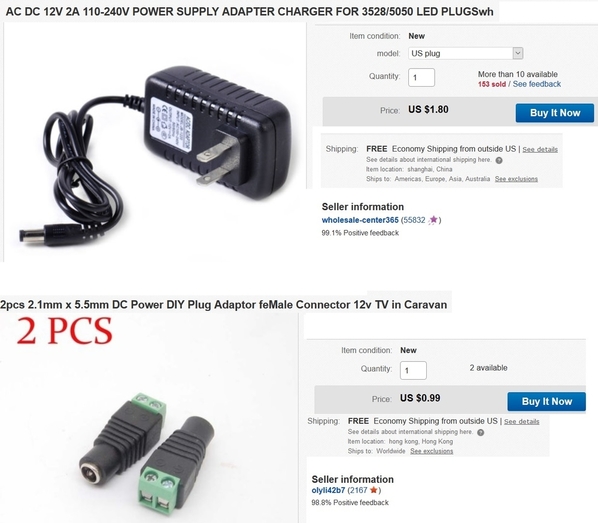

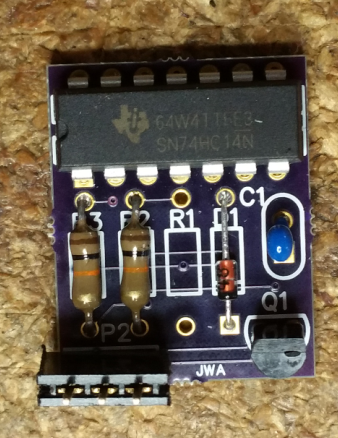

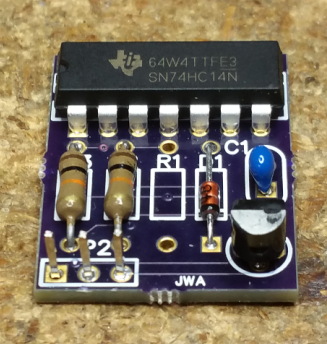

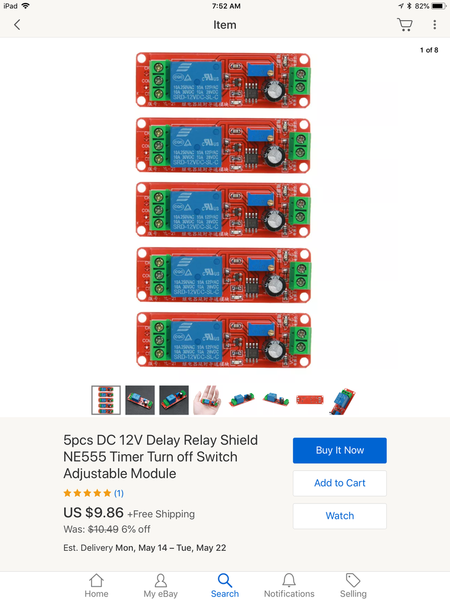

This uses the eBay ~$1-per-relay modules that GRJ identified and an external ~$2 DC wall-wart. Each relay module, whether it be 1,2,4,8,etc. relays always receives DC power direct from the wall-wart. This wiring carries a "medium" amount of current so something like #22 or #24 wire is fine. Each module will have DC+ and DC- inputs for this power. DC+ may be labeled VCC, and DC- may be labeled GND.

For every relay, there will be a control or trigger signal on the module. So a 4 channel relay will have 4 control inputs typically labeled IN1...IN4 or CTRL1...CTRL4. These signals come from the AIU.

Let's just say we have 8 relays to control broken up into a 1-relay module, and 2 4-relay modules. 1 relay on the 2nd 4-relay module is unused and can be used later if you, say, add a new controlled siding.

Let's say we assign the 8 relays to ACC1 to ACC8 on the AIU. When you select one of the Accessory outputs on the DCS Remote handheld and press the "ON" softkey, the AIU will send the control signal to the corresponding relay module which activates the physical relay. These control signals (blue lines in pic) carry very little current so can be something like #28 wire. #28 wire is the typical gauge used on those multi-conductor ribbon cables used in computers that you can often get really cheap surplus. The relay under control then switches power to the controlled siding/whisker/spur. By placing the relay physically close to the controlled track section this minimizes the length of high-current track-power wiring which is always a good thing. Your track wiring is probably something like #14 or #16.

It sounds like you can control all your relays with a single AIU...but note that there is the question of where to physically locate the AIU. You probably are using just the short 1 foot modular-plug phone cable between the TIU and AIU. But in sketching out the wiring plan, you can imagine a scenario where maybe it would be easier/neater to physically locate the AIU further from the TIU using a longer modular phone cable. Hard to say but this is part and parcel of doing the right thing before doing things right.

Another thought is whether you want some kind of visual feedback of the various relay positions. The eBay relay modules have individual LED indicators showing if the relay is ON (a 4 channel relay module will have 4 LEDs). Obviously these are on the board itself so if the board is attached under ground then it not as useful. As you know (or may be doing right now) most layouts with a control panel with toggle switches to control block power have lights next to each toggle switch to indicate block is ON. So if you want some kind of centralized panel with similar status indication, draw those connection into the diagram too.

Hopefully this is enough to move the ball forward a bit.

![]() I don't fully understand relay speak so if someone could spell out exactly what I'm looking for it would be appreciated.

I don't fully understand relay speak so if someone could spell out exactly what I'm looking for it would be appreciated.