My Ives 3250 has been exhibiting this problem on and off for awhile. The parts and wiring are all original except for the bulb in the light and a bell I added, probably the rollers too. That said- I want to keep it original. If you want to skip the read, see the last picture.

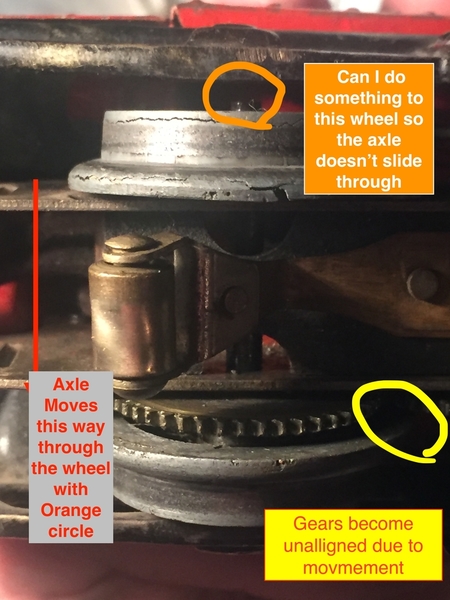

Problem: The rear axle is loose, it slides through the rear wheel, causing the gears to become unaligned.

*NOTE-THE WHEELS NO LONGER ARE CRACKED* Like in the picture. My repair guy put a substance(can't recall the name) on the wheels which filled in a lot of those cracks and strengthened them-that has held fine.

Previous attempts to repair:

1.) I temporarily fixed it myself with loctite(read it on a forum)- worked but only for while obviously as eventually the loctite slowly broke apart.

2.) Went to have it done by my very trusted repair guy, but it started exhibiting the issue again within a week. I believe he remounted the wheel

3.) I remedied a similar situation once by placing a lock washer on the axle on the exterior of the wheel through which the axle slides- not working as well here.

Possible Source of Problem:

1.) Dreaded Zinc Pest. Wheel could have expanded

2.) Wheel is not on the Axle properly. It doesn't look as if it's mounted the same as the front wheel. Somehow my repair guy's work became undone. I'll post a picture of how the wheel currently looks ASAP

Current Possible Solutions:

1.) Secure the axle from the exterior of the wheel with something like the lock washer

2.) Add a spacer(s)

3.) Reposition/remount the wheel- if needed

Your help is sincerely appreciated!

Steve