The magnet on my Fastrack uncoupling track is fried. How is the Uncoupler magnet assembled to the track piece? I want to take it out and rewind it. Visually it appears that only a few of the outer turns are the ones affected, so if I can get it out, it might not be too difficult to repair the magnet's windings. I couldn't find anywhere else on the web with hints or instructions on how to do this, but if it was assembled, there must be some way to disassemble it. For those who want to be sure I'm not barking up the wrong tree, I have continuity in the wires from the button switch. The magnet coil measures at 1.5 Ohms. I have no idea what an unfried magnet's ohm reading is though, but my guess is an ohm or two higher. I directly powered the magnet leads with 10-15 volts and there was no magnetism produced. How is this magnet assembled into the track? I can't see the lines distinguishing where the magnet is inserted into the track section's top or I'd have a better idea how to take it apart.

Replies sorted oldest to newest

Uncoupler magnets should be 5-7 ohms.

Looks like quite a bit of damage to the plastic as well, you might be better off just buying another one.

John is right. It is now a 5” fitter piece of FasTrack. If you do replace it, you should also replace the button with a better one, i.e. one that won’t stick.

The conventional wisdom is to toss it, but I don't like to do that for an item that has the same flaw. Do you guys have any idea how the magnet is assembled into the track section? Getting it out without destroying it is the challenge. Even if it's warped, that might be able to be heated and warped back up once it's out of the track segment.

ADCX, thanks for the information on the ohm reading of a good magnet. It won't help me this time, but such information is important to others doing troubleshooting.

The flaw is in the button.

Yes, usually the controller.

Although they look like the originals, they are really chincey.

R Lamparter posted:ADCX, thanks for the information on the ohm reading of a good magnet. It won't help me this time, but such information is important to others doing troubleshooting.

I haven't had time to study the construction of one of ours yet, if a get a look I will address that part of your question!

My hunch is that I need to remove the outer rails, (which I'm suspecting are hiding a seam) and the accessory rails and then the magnet can be removed from the top side. I don't want to start disassembling things unless I have to because there are a lot of connections to unsolder and it would still work as it is to unload old style cars with their own electronics.

I misunderstood. Sorry. When you said uncoupling track I took it to be that. Those controllers stick all the time. The operating track is more involved. I still think the controller must have been on too long for that amount of heat to be generated, either by sticking or being held.

R Lamparter posted:The conventional wisdom is to toss it, but I don't like to do that for an item that has the same flaw. Do you guys have any idea how the magnet is assembled into the track section? Getting it out without destroying it is the challenge. Even if it's warped, that might be able to be heated and warped back up once it's out of the track segment.

I repair lots of stuff, but I also evaluate the specific item and make a decision on fix or toss based on the likelihood of a successful repair. The cost of the item in question also enters into the picture, for a relatively cheap item, I'm more likely to come down on the "toss" side. In this instance, I deem that likelihood or a successful repair as being fairly small with all the warped plastic. I'm certain that the time involved in a repair of this type, even if successful, would be excessive and better spent on three or four repairs that have much higher probability of success.

Obviously, this is just my opinion, and I don't presume to tell you what to do or not do.

If these two tabs (would require unsoldering the right one) were bent 90 degrees upwards, does the coil assembly wiggle/loosen? There might might be corresponding tabs on the other side.

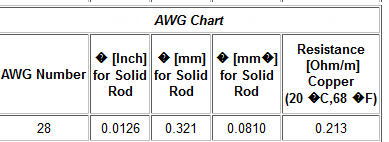

Also, if the nominal resistance is 5-7 Ohms and you're measuring 1.5 Ohms, it seems the "short" might be buried many feet into the winding...rather than just an easily accessible outer layer. Not Fastrack but in this recent roll-your-own uncoupling magnet thread, I estimated a Realtrax coil at 80 ft of #28 magnet wire, 600 turns, 5.3 Ohms. Would be nice to know the Fastrack coil parameters to add to the collective knowledge.

Attachments

Attachments

Dave that's a really helpful photo even if it implies the difficulty / impossibility of the repair. Knowing that it's just glued, it seems that the approach has to be to get under the glue first. In a commercial sense I agree with John that this is not economically repairable, however when you're retired and have always been one to tinker...... It was a Christmas present to my grandson last year.

Having seen Dave's photo, I started to work the edge of the coil up, first with a small spatula and then with a putty knife with a slightly thicker blade. I was able to sneak a broad tipped screwdriver underneath and twist to pry it off the plastic a little. This is as far as I wanted to go tonight. I wanted to prove the concept that it can be lifted and sleep on thinking about a better way to do it. Paint thinner isn't likely to dissolve/melt the plastic, but depending on the glue it might soften the glue. A heated spatula, somewhat under the melting temperature of the plastic and the wire's varnish might work. If I'm successful at rewinding/repairing this, it's getting a resettable fuse soldered in so this doesn't happen again.

Attachments

I renew my advice. ![]()

Not sure a fuse will help. It's the heating over time on that does the damage.

A properly sized PTC is probably a better choice for protecting the coil.

What's a PTC stand for John? It will probably be obvious when you tell me, but I'm blanking at the moment. The idea for an automatic resetting fuse (0.5A) came from a message somewhere else. I haven't made much progress today so far getting the coil off.

These will break the current when excessive current is detected and reset after the overload is gone. I'd try a 1A trip spec for this application to see how that works.

That's what I had in mind. I just replaced one in my train surge/spike suppressor. When you say 1A. Do you mean the one that holds at 0.5A and actually trips at 1A or one that holds at 1A and actually trips at 2A? And the magnet is out. Photos tomorrow.

Attachments

As far as trying to produce the strongest magnetic field possible, so that the coil can be mounted completely under the table and use a longer pole, has anyone ever tested using DC to power the coil, especially a full wave rectified, or even capacitor filtered DC. I would "think" that a relative smooth DC would provide the greatest magnetic field production. The only negative I can think of is that the pole piece might become somewhat permanently magnetized.

The value of the PTC may have to be determined experimentally, I don't know exactly what the coil draws, though I believe it's several amps when energized. However, you only want it energized for a second or two, so a lower trip rating may work as these aren't the fastest acting devices on the planet.

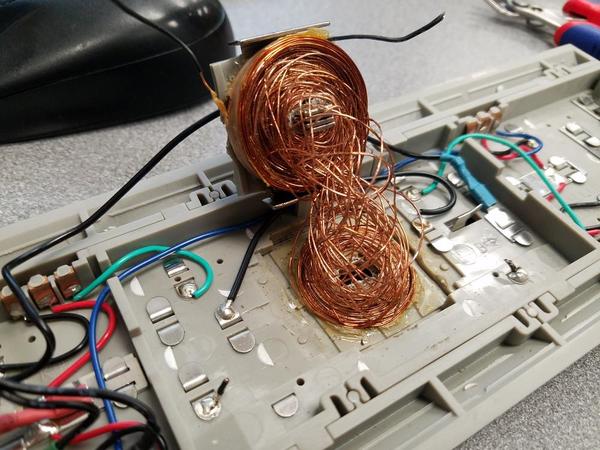

OK. Here are the disassembly photos and information I promised. Items I used to pry the magnet from the track: narrow chemistry/artist's spatula, putty knife, cheap woodcarving chisel, broad bladed screwdriver. Heating to 400º F (measured with a non-contact thermometer) on a hot plate did not help the removal. Paint thinner did not soften the glue or melted plastic adhesion of the coil. Inserting the spatula and putty knife as far as I could followed by twisting a broad bladed screwdriver blade under the magnet was the most effective method. Here's the magnet half way off. As you can see, a few of the wires were damaged.

Here's the core of the magnet being drawn down.

Here's the magnet once it was out.

Next is the underside and top side of the track with the magnet out.

Next comes the task of disassembling the magnet's core in order to unwind the magnet. The metal "wings" on the side of the assembled magnet keep it from easily being wound or unwound. In the first photo, I've pushed up the two center wedges.

And here you can see them raised up

Note that the two wedges have a side tab that seems to be used for locating their height. Hmm. Not sure why that text turned blue.

The flanking parts of the core needed to be tapped out and weren't released by the center wedges.

Finally the core is out leaving full access to the windings. The windings are also glued to the plastic base of the magnet. There are a lot more coils of wire in this thing than I anticipated despite Stan2004 mentioning 600 wraps.

And here's the magnet next to the cores and wedges

The magnet's wire measures 0.014" with its insulating varnish. That's either 27 or 28 ga wire. I guess my next move will be to start by removing the wire at the top that I damaged and see if I can find the short. It might be easier to just buy some magnet wire on ebay and wind a new one, perhaps using a different core like the sewing machine spool mentioned in the discussion on repurposing old RCS track electromagnets. If old RCS track were readily available, it would be easiest to glue one of those magnets into this track section and adapt the top and that's probably the most efficient way to repair one of these.

Attachments

R Lamparter posted:... The magnet coil measures at 1.5 Ohms. I have no idea what an unfried magnet's ohm reading is though, but my guess is an ohm or two higher. I directly powered the magnet leads with 10-15 volts and there was no magnetism produced.

If #28, that's about 15.4 ft/Ohm. So 1.5 Ohms would be about 20-25 feet of wire. That's still a heck of a lot of turns around the core...any buried short notwithstanding. What's confusing is why you got NO magnetism with 10-15V on a 1.5 Ohm coil. That's 6-10 Amps or so. Point being, the magnetic force on the coupler-disc is proportional to the Amp-Turn product. So even though the # of turns dropped, the smaller coil resistance means the current increased...and the Amp-Turn product remains the same. ![]()

R Lamparter posted:The metal "wings" on the side of the assembled magnet keep it from easily being wound or unwound. In the first photo, I've pushed up the two center wedges.

Are you saying the wings must be in-place to allow winding or unwinding? I'm trying to imagine how you're going to manually wind a new coil (if you start from scratch). It looks like in your last photo the wings come off completely and you could start winding un-impeded by the wings? Anyway, are those steel (ferrous) wings? Seeing as to how those wings go right into the core section, I'm thinking those are creating a magnetic path - first time I've seen that configuration in an uncoupling coil. I'd be interested in knowing how much it improves the pulling force vs. a solid steel bar in the core.

Also curious your thinking on how much wire to use if starting from scratch. How do you know when you're done if you don't know how many turns you need? It's hard to tell from the photo how "methodical" the coil winding is (i.e., if it was done with a machine or with really low-cost labor). I suppose you can just keep winding till you run out of space and then just adjust the driving voltage accordingly until it reliably works. Any documentation would be nice to have for the record.

I sure wouldn't try to re-use the existing wire, buy new wire.

Here is some PTC info for Fastrack uncoupler tracks that others have used successfully. 3rd item down on the list.

PTC and TVS - Some Commonly Used Sizes and Part Numbers (from other threads)

stan2004 posted:R Lamparter posted:... The magnet coil measures at 1.5 Ohms. I have no idea what an unfried magnet's ohm reading is though, but my guess is an ohm or two higher. I directly powered the magnet leads with 10-15 volts and there was no magnetism produced.

If #28, that's about 15.4 ft/Ohm. So 1.5 Ohms would be about 20-25 feet of wire. That's still a heck of a lot of turns around the core...any buried short notwithstanding. What's confusing is why you got NO magnetism with 10-15V on a 1.5 Ohm coil. That's 6-10 Amps or so. Point being, the magnetic force on the coupler-disc is proportional to the Amp-Turn product. So even though the # of turns dropped, the smaller coil resistance means the current increased...and the Amp-Turn product remains the same.

R Lamparter posted:The metal "wings" on the side of the assembled magnet keep it from easily being wound or unwound. In the first photo, I've pushed up the two center wedges.Are you saying the wings must be in-place to allow winding or unwinding? I'm trying to imagine how you're going to manually wind a new coil (if you start from scratch). It looks like in your last photo the wings come off completely and you could start winding un-impeded by the wings? Anyway, are those steel (ferrous) wings? Seeing as to how those wings go right into the core section, I'm thinking those are creating a magnetic path - first time I've seen that configuration in an uncoupling coil. I'd be interested in knowing how much it improves the pulling force vs. a solid steel bar in the core.

.................

I'm not sure how this quote system works. I'm not seeing it highlight your text so I'll put dots between our messages. The wings must be removed if you're going to use the plastic "core" to wrap the coil around. The side wings of the core impede access to the coil, but I assume they're there to pick up some magnetism from the periphery and channel it to the central core.

.................

Also curious your thinking on how much wire to use if starting from scratch. How do you know when you're done if you don't know how many turns you need? It's hard to tell from the photo how "methodical" the coil winding is (i.e., if it was done with a machine or with really low-cost labor). I suppose you can just keep winding till you run out of space and then just adjust the driving voltage accordingly until it reliably works. Any documentation would be nice to have for the record.

..................

I haven't carefully thought out what to do next. I'm glad you guys are kibbitzing. It will help me figure out how to proceed. I only dabble with electronics occasionally and defer to the voice of experience. I see magnet wire on ebay isn't very costly, so my initial thought is to buy enough wire that I could potentially wrap more than one coil and just wind till the outer dimensions match the original. The coil appears very orderly and was probably created by a machine.

RTR12, thanks for the links to the references.

|

I checked an O-27 uncoupler - it's wound with 28 gauge wire, so for a nominal 6 ohms, you're looking at about 110" at 65 ohms per 100'.

Rob, your numbers are way off from where I checked.

30 meters of #28 would be about 6.39 ohms! 110" would be more like .6 ohms.

Attachments

My decimal places are off!

1100" / ~92'

Something is still wrong. It doesn't appear that 92' would fit on that spool under the red track button. Maybe it does!

If the coil is really 6 ohms, they have to fir around 100 feet on that spool somehow. ![]() All of mine are packed for the move or I'd measure one.

All of mine are packed for the move or I'd measure one.

Just measured a NIB Fastrack uncoupler, 5 ohms, 10 milliHenries.

28 AWG is .064 ohms/foot, 5/.064 = 78 feet = 937 inches. This all assumes the coil is really #28. I didn't verify that, but I have no reason to doubt it.

Regarding protecting the coil with resettable fuses, I use a .5A hold, 1A trip device. I run my uncouplers on a fixed 14 volts.

The uncoupler is used on an entry level Lionel train. My son says the wall wart / transformer is 18 V and I think DC. I'm not sure there's a lower voltage outlet to run accessories with that tranformer. Would there be any advantage in making a new coil with somewhat larger or smaller diameter wire to keep it from burning out? ... and I don't know enough about magnets to know whether to use larger or small diameter wire to build in more reserve, or whether I'd be losing magnetic strength in the process of changing the original wire diameter.

One thing to be aware of is your measurement tools when measuring low resistance items. Most inexpensive meters will have trouble accurately measuring 5 ohms. I suspect PLCPROF has a quality meter, so I'd go with the 5 ohm value.

R Lamparter posted:RTR12, thanks for the links to the references.

You are welcome.

It is PLCPROF's info that is in the list for the uncoupler track. See his post above, he has added some more info about it.

R Lamparter posted:The uncoupler is used on an entry level Lionel train. My son says the wall wart / transformer is 18 V and I think DC. I'm not sure there's a lower voltage outlet to run accessories with that tranformer. Would there be any advantage in making a new coil with somewhat larger or smaller diameter wire to keep it from burning out? ... and I don't know enough about magnets to know whether to use larger or small diameter wire to build in more reserve, or whether I'd be losing magnetic strength in the process of changing the original wire diameter.

It's about the Amp-Turn product or number of coil Amps times number of coil Turns. If you use smaller diameter wire, sure you can wrap more turns in the same volume...but the smaller wire has more resistance per foot. So the overall coil resistance goes up and for the same applied voltage there is less current...and the Amp-Turn product might be the same with no effective change in magnetic strength.

For uncoupling coils, there is some logic to choosing the coil current. That is, most guys typically run their uncoupling coils from accessory voltage - 14-16V AC. Typical accessory outputs can deliver just a few Amps...not 10 Amps like the main track outputs. Yes, you only draw on the accessory power in spurts when firing an uncoupler, and it's rare to fire two or more at the same time. In any event, common sense suggests a current of, say, 2 Amps is a practical choice.

Unfortunately, the math gets a little tedious with coils driven by AC voltage. Most guys only have a meter that measures Ohms as DC resistance measurement. So you apply Ohms Law, I=V/R and conclude that applying V=14 to a R=5 Ohm coil would be a coil current of I=2.8 Amps. Seems like too much. But wait. As PLCProf notes the coil has an inductance of 10 mH. That represents a 60 Hz AC impedance of Z=4 Ohms. (Z = 2 x pi x frequency in Hz x Inductance in Henries). So the 10 mH (0.01 Henry) coil is really a ~9 Ohm impedance at 60 Hz (you add the 5 Ohm DC resistance to the coil's 4 Ohm AC impedance). The coil current is really closer to 1.5 Amps. The point is 1.5 Amps is a "good" number in that it's something pretty much any accessory output from a train transformer can provide.

Now you throw a DC wall-wart into the mix. At DC there is no AC impedance since DC = 0 Hz. This means the 5 Ohm coil resistance is all there is...and the 18V DC applied to the 5 Ohm coil will draw a 3.6 Amps DC. If your DC wall-wart can support that much current then great because you will indeed generate more Amp-Turn magnetic strength.

But wait, there's even more! The AC current is sinusoidal so that 1.5 Amp AC current has a peak current of about 2.1 Amps. Those coupler discs move very quickly and you really only need a fraction of a second to overcome that retention spring. But in any case 18V DC still generates a higher Amp-Turn strength vs. 14V AC.

So bottom line. If you have an 18V DC supply that can deliver the goods (the Amps), you may not need as many turns. I'm just guessing but I'd say if you hand-wind a coil of hundreds of turns that you lose maybe 20% (?) in number of turns simply because you can't wind the wire as well as an automated winding machine.

FWIW. I kept getting wire diameter measurements in between 27 and 28 Ga so I pulled out a real micrometer instead of the vernier calipers (intentionally mispronounced as "very-near" calipers by some machinists for good reason) that I had been using for convenience. I'm getting .0147" to .0149" with the enamel on. This fits better with 27 Ga wire even if postwar uncouplers were wound with 28 Ga. It would seem Fastrack uncouplers are wound with 27 Ga wire rather than 28 Ga wire.

With a micrometer, you have to take account the enamel coating.

|

The measurement was with the enamel coating on. At .0149'' it was closer to the expected coated range of 27 Ga (.0149" to .0155'') than to 28 Ga (.0132'' to .0139'') I tried paint stripper on it but the coating didn't come off. I was hesitant to scrape it off because there is so little difference in diameter between the two gages. For other reference, the existing coil measures about 1-3/16" Dia. and 3/8" thick.

I wound the coil this afternoon. I used a long #8 screw as the arbor. I had to "shim" the central square box that the arbor ran through with some small pieces of sheet metal to keep the spool square to the screw. I used a large fender type washer on the opposite end to contain the free end of the coil. It was not easy to keep the wire evenly spaced as I did the winding. I did the best I could. Note that it taped the loose end to the bottom of the spool and wound new wire over the tape buffer rather than risking scraping any coating off that lead. I carefully wound the first layer by hand and kept it reasonably even. After that, I unspooled about 10" of wire from the stock coil and held light tension on it, guiding the wire from side to side as it accumulated on the new coil. I ran the drill at a creeping speed till my hand was close to the spool and arbor, and then repeated the process. When the coil was about the same diameter as the original, I cautiously loosened the nut and started to pull the fender washer away, but the wire looked like it might start to spring off the loose end of the coil, so I tightened it back up. I painted some clear lacquer on the coil and will try removing the washer and coil from the arbor when this is completely dry. I may put a coat of lacquer on the loose end of the coil once the washer is removed. Then it's on to reassembly and testing assuming the coil stays together.

Attachments

Yes, but did it work? ![]()

What gauge did you end up with, how many feet, how many turns, etc.?

I used 27 Ga wire. I didn't count turns and just wound it until it was about the same diameter as the old one. I bought 400 ft of wire that should have been enough for more than one coil and it was. I'm getting about 6 ohms resistance from the coil and that fits with the 5-7 ohms for the factory coils earlier in this discussion. I won't know if it will work until I get it reassembled. Any tricks for getting the coating off the magnet wire? Scraping with a knife didn't work very well. Pulling it through a folded piece of emery paper worked, but it seemed slow to get it to bare wire and cleaning of the varnish was inconsistent.

I "burn" off the coating by feeding it into a blob of molten solder and lots of flux. Takes, say, 5-10 seconds and you end up with a nicely tinned 1/2" end. I hope that makes sense. I'd think there are youtube video of this...but if not I can make one if that would help. I've done this many times and has always worked for me.

I discovered today that I had put too much height on the coil. I need to remove the wire and rewrap the coil. The plastic core must touch the underside of the track.

Well, I completed the rewind and installation and it kind of works. I used jumpers from my tubular 3 rail track to power the Fastrack section and test it with the voltage reading about 17 V on the meter. Some couplers are attracted to the magnet and it doesn't have enough oomph to grab some other couplers. I don't have an action car with a center magnetic stem to test that action. I'll have to wait until it's installed on my grandson's set again with his power supply to see if it works like it used to.

I used 27 Ga wire rather than 28 Ga like the older tubular track couplers are reported to be wound with. Would magnetic attraction have been stronger with more turns of the smaller diameter wire? I was not able to keep the turns of wire even on the coil when wrapping by hand under power even when it was turning at a creeping speed. Thus there are not as many turns of wire as there could have been. I might have been able to wrap it more evenly if I had wound it completely by hand, but it would have taken hours to wrap the coil. The top of the magnet core is not completely even with the two outer rails. It's not lower by much - an estimated 1/64". Is that a significant amount with respect to the magnetic action on couplers / action cars? I was able to gain a little additional height by pushing the two central metal core spacers up a little above the two on the outside.

I don't know that I'd want to consider this done and a complete success. It's more of a proof of concept that it can be done and needs refinement. I think this repair would now take about an hour to an hour and a half. Probably not economically feasible for those of you doing commercial repairs, but for the hobbyist, it's doable. When I first asked the question I hoped that somebody else had already done this and had worked out the best way. A different spool and core rather than reusing the one from the Fastrack might be a way to allow more rapid and even winding. Cannibalizing the magnet from an old piece of RCS track would be another way. Photos of the bottom with the rewound magnet installed and the top as it exists now are below.

Attachments

Yes, more turns of smaller wire yields a stronger magnetic field. I know that in the Kadee world, using DC instead of AC with their e-m uncouplers, also produces a stronger field at the same voltage. Just be sure you use a good quality momentary contact switch, that reliably turns off when released, or you'll still have meltdowns. And only hold the button for a second or so to prevent heat buildup.

Bill in FtL

Well, more turns of smaller wire "might" yield a stronger magnetic field, it all comes down to the number of ampere turns on the coil. For the same applied voltage, that statement is not necessarily true as the smaller wire and more turns will have more resistance and also more inductance. This will result in less current flow at a given voltage.

Also, the fact that the coil is lower now due to melting has significantly reduced the magnetic force, the force drops as to the square of the distance, so a small gap can have a large effect. That coil used to be slightly above the track plane, now it's visibly below the track plane. That has had a major effect on the magnetic force to the couplers.