HELP?!?!?!

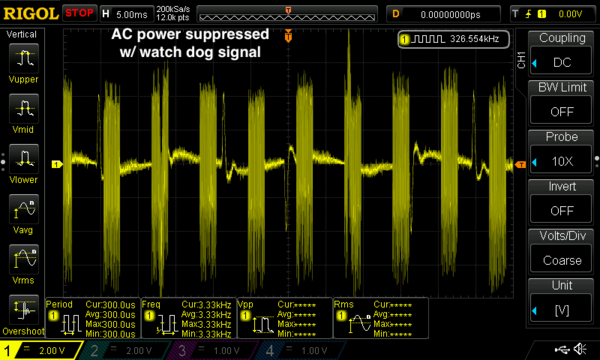

I did more testing, and here are the results:

I'm really surprised to say that replacing the 74ACT244 and MAX6439 did not fix my problem at all. After I found it didn't solve the problem I went nuts and just measured everything to show the difference between a good and bad channel. This TIU was literally working about a week ago, so I'm thinking to rule out cold solder joints and two transformers suddenly having a problems on two different channels...

If anyone can suggest what part to look at based on what I'm seeing, I'd appreciate any thoughts. Here we go:

First the parts I replaced with hot air rework:

After these were replaced I measured again. Still the same problem.... two weak outputs. This is just one of our TIUs, I actually looked at 3 in detail. The weak signals are not always on the FIXED (That's just this particular part I'm posting here, sometimes they are on the VAR outputs).

Here's the measurements after the parts have been replaced. The problem persists.

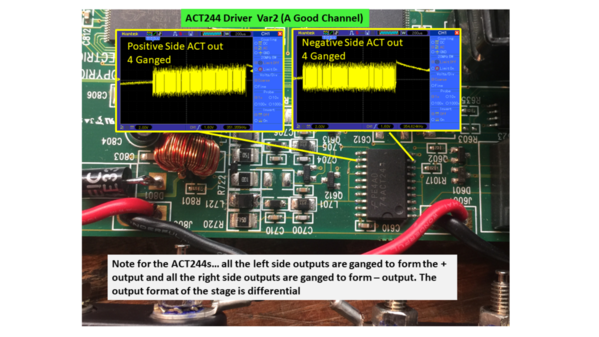

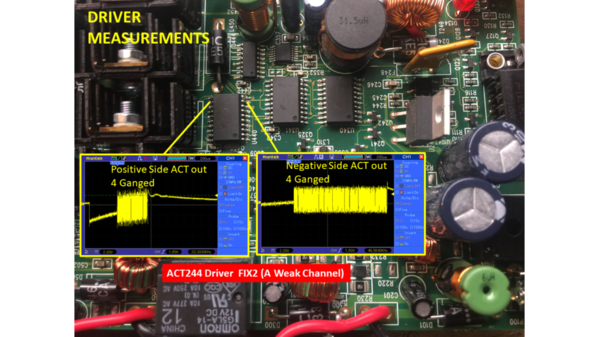

I thought it would be wise to check out the 74ACT244s directly so here they are:

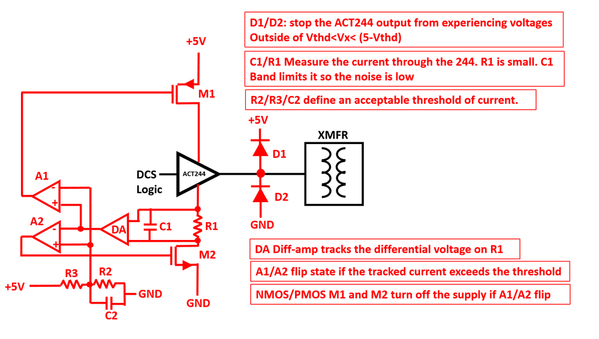

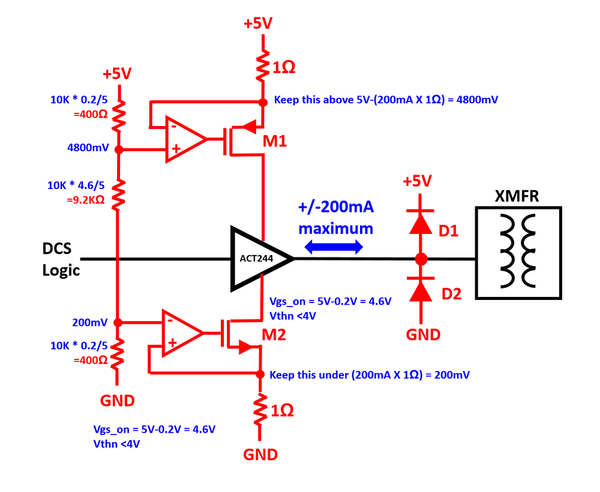

The voltage swing looks pretty much the same in both the good and bad channels so I feel it's safe to say the ACT244s are working fine. From my understanding of the traces on the PCB it looks like they the 4 left channels together to form a positive output and the 4 right channels together to form a negative output, then use it differential to drive the output transformer after a filtering network. I don't understand the filtering network too well since I don't have a schematic.

Given this case I measured the ACT244s deferentially also to make sure there wasn't something the single ended monitoring wasn't capturing.

Again in differential mode both the weak and good channels have about the same voltage swing. If you zoom into the individual bits inside both look like clean square waves.

Next I traced into the output network after the ACT244 as far as I could. Again I don't have a schematic so I don't really know what's going on. If you follow the next 3 pictures I go through some type of 3 stage filter. At the output of the filter the signal is good for the good channel but weak for weak channel. I swapped all the passives between the ACT and the point where the bad signal appears (I think it's 3 series inductors) but the problem didn't move channels so it seems those surface mount devices are okay.

GOOD CHANNEL:

BAD CHANNEL:

So that's as far as I've gotten in troubleshooting. Not having a schematic makes troubleshooting really painful. I don't really understand exactly what this network does, and there are some discrete transistors in there so it's hard to understand exactly what's going on. Clearly something here is killing the signal swing since up to the 2nd stage the weak and good channels look identical.

We have about 11 TIUs in our club with 2/4 or 3/4 channels in this condition, that worked just a few weeks earlier. Once this happens the channel is basically unusable on the layout so I'm really trying to find answers. We find if we have a TIU with only 3/4 channels connected to the layout, then the unused channel never has this problem, this only happens to channels in use which is why we think it's related to operation (probably short circuits). Again it's hard to believe that the ACT244 isn't breaking and something in the output network is... but the measurements are what they are.

Looking for any help from the smart and way more experienced people on here...

-Adrian