I am attempting to install a Sunset TAS smoke unit in a MTH premier f3 diesel.I have tried using plastic aquarium tubing into the top of the smoke unit but it gets too hot for the tubing.I have brass automotive fittings that I can mount into the top of the smoke unit but I would like a recommendation as to what adhesive would stand up to the heat and not get soft or melt.I tried looking on the MTH website to see how they plumb smoke unit tubing from the factory but had no luck.I would appreciate any advice from someone that has done this install before.Thank you.

Replies sorted oldest to newest

The F3 has two stacks, so there's a split funnel that pipes the smoke to the two stacks.

JB-Weld will stand up to high temperatures.

J-B Weld is water-resistant, petroleum/chemical-resistant (when hardened), and acid-resistant. It also resists shock, vibration, and extreme temperature fluctuations. J-B Weld can withstand a constant temperature of 500 °F (260 °C), and the maximum temperature threshold is approximately 600 °F (316 °C) for 10 minutes.

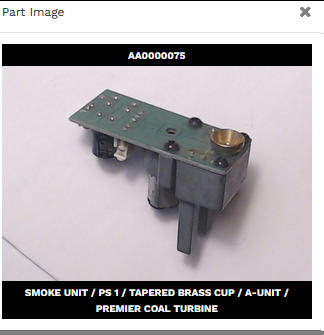

Wouldn't it be nice to find a TAS smoke unit with the F3 funnel already attached? WAIT! I have such a smoke unit, drop me a line and it can be yours.

This is the TAS smoke unit out of a 3rd Rail F3, it has the two stacks exactly spaced for a scale F3.

Attachments

Thanks for your reply.is that funnel piece in the picture meant to mount directly under the exhaust openings of the f3 shell or is there additional tubing needed to attach to the brass oval openings and then piped up to the shell.

I would have used the MTH correct smoke funnel for that engine- but that's just me.... Even further, I might have adapted a PS1 style smoke unit with the correct spacer legs, since this was going into an MTH chassis. I get wanting to use the TAS unit, and adapt. Otherwise, I would replace the resistor in a PS2/3 style unit and then have separate power and control for the fan- there's a lot of ways to skin this cat.

https://www.mthpartsandsales.com

| AA0000054 |

Attachments

Again, it's this simple- they screw the plastic smoke funnel to the shell to give the 2 stack outputs.

mates to this on the smoke unit

mates to this on the smoke unit  which is either already on the smoke unit or screws into the exit hole, also notice the post mounting height of the unit is fairly standardized.

which is either already on the smoke unit or screws into the exit hole, also notice the post mounting height of the unit is fairly standardized.

It has a mating cone shaped connection that fits right over the MTH smoke unit cone shaped brass funnel. This mates and aligns when the shell is installed.

Also, in many cases, the standalone smoke unit AKA PS1 has the same metal cup and mounting post location so in a given frame in can align to existing MTH mounting holes- simplifying adaptation.

or even a this one from the coal turbine has the correct mating cup

Attachments

Again, sorry for interjecting, but I just feel like there are a bunch of ways to adapt and install a smoke unit but some are a lot more work in my opinion, custom fabrication and so forth.

If you started with an MTH chassis and shell, staying at least with MTH mechanical parts (the smoke duct, the smoke cup (heating chamber), the standardized top PCB, the fan unit- even if you decide for space and other concerns you need to remote mount fan control and change the resistors to suite how you need to power and control the unit.

Again, you have an offer for a known TAS unit with duct that may or may not require mods to align to the MTH shell outlet hole spacing and location, but then also need to solve the overall smoke unit mounting problem.

Also, you can go anywhere in-between solutions mixing and matching. Use the MTH smoke duct and adapt the TAS output funnel to the MTH one and solve the mounting location.

I just feel like for many folks, again, if you start with an MTH chassis and matching shell, I would keep as much of the MTH mechanical/physical smoke unit parts (especially the shell mounted duct), making alignment and mounting just that much easier and more reliable IMO.

As always, your train, your rules, and ultimately your time and money.

Thanks Vernon for your reply/info.I have mounted a TAS smoke unit into the MTH 20-21583-4 B&O F3 non-powered chassis. The smoke unit did not come with a funnel and the hole where a funnel goes is not threaded internally.So I have small brass automotive fittings that are T shaped.I think I am going to follow GunnerJohn's recommendation and use JB weld to secure the fitting into the smoke unit opening.Then from the two openings on the brass fitting run tubing up to the openings in the underside of the shell. I think it should work.What do you think?

@joe woods posted:Thanks Vernon for your reply/info.I have mounted a TAS smoke unit into the MTH 20-21583-4 B&O F3 non-powered chassis. The smoke unit did not come with a funnel and the hole where a funnel goes is not threaded internally.So I have small brass automotive fittings that are T shaped.I think I am going to follow GunnerJohn's recommendation and use JB weld to secure the fitting into the smoke unit opening.Then from the two openings on the brass fitting run tubing up to the openings in the underside of the shell. I think it should work.What do you think?

It's your train and you got the offer of one solution free, so I'm not saying don't use that or try to use that. Maybe it fits perfectly to the shell, maybe it doesn't?

Honest personal assessment of typical problems with DIY smoke ducts:

#1 filling the smoke unit later and not getting leaks or air blockage from drops or bubbles. Horizontal paths are probably the worst offender.

#2 heat related problems of the DIY smoke ducting funnel transport system melting, coming unglued, other failures and leaks. What glues and plastics hold up to the heat can be a challenge. Soldering an all brass or metal one is possible, but then details like horizontal paths, smoke filling operation, long term operation and viability- and a huge last one- heat conduction to the shell- all also come into play.

#3 making the whole thing (both the smoke unit itself, and the shell removal and replacement process) easy to service later should the wick or fan motor need replaced or attention.

As a complete discussion- the overall hobby and folks skillsets comes into play. Example, some people like myself are good at electronics, not as good at paint and other cosmetic detail oriented modifications- so for me- using known mechanical mounting and components by reusing MTH parts in an MTH train makes the most sense- and adapting or building simple smoke heater and fan control circuitry is the trivial part for me.

Some people might not be as electronically oriented, they have to treat modules as plug and play. So, then they are more forced into using a given smoke unit "module" example TAS, and then DIYing the smoke duct and mounting. As you have already seen, the heat can be a factor in the DIY solution and might require trial and error. With that- I'm also throwing in the chances of melting the duct, melting the shell, leaks, usability, filling of the smoke unit with creating air traps and so forth.

Joe, I’d buy the MTH F3 smoke funnel that Vernon referenced, mount a stub piece of brass tubing to it, and affix it to the roof for good. Then add a stub brass piece to the TAS smoke unit, & finally connect the two with a hose,….you can get small diameter silicone hose off all the popular shopping venues for small money,……silicone hose won’t care about the heat from a smoke unit,….

Pat

Thank you for all your ideas and suggestions.i now have a few options.

@gunrunnerjohn posted:The F3 has two stacks, so there's a split funnel that pipes the smoke to the two stacks.

JB-Weld will stand up to high temperatures.

J-B Weld is water-resistant, petroleum/chemical-resistant (when hardened), and acid-resistant. It also resists shock, vibration, and extreme temperature fluctuations. J-B Weld can withstand a constant temperature of 500 °F (260 °C), and the maximum temperature threshold is approximately 600 °F (316 °C) for 10 minutes.

Wouldn't it be nice to find a TAS smoke unit with the F3 funnel already attached? WAIT! I have such a smoke unit, drop me a line and it can be yours.

This is the TAS smoke unit out of a 3rd Rail F3, it has the two stacks exactly spaced for a scale F3.

Thank you for your suggestions and advice.How much do you want for the smoke unit? How can I pay you?Also what do you suggest as tubing to go from the brass oval outlets on the smoke unit to the underside of the F3 shell roof?Thank you Joe Woods

@joe woods posted:Thank you for your suggestions and advice.How much do you want for the smoke unit? How can I pay you?Also what do you suggest as tubing to go from the brass oval outlets on the smoke unit to the underside of the F3 shell roof?Thank you Joe Woods

@gunrunnerjohn posted:Wouldn't it be nice to find a TAS smoke unit with the F3 funnel already attached? WAIT! I have such a smoke unit, drop me a line and it can be yours.

Not sure if I am responding correctly.I wanted to know how much you want for the smoke unit and how can I pay you? Also what tubing would you use to go from the oval openings on the smoke unit to the exhaust openings in the roof of the F3 shell?

@joe woods posted:Not sure if I am responding correctly.I wanted to know how much you want for the smoke unit and how can I pay you? Also what tubing would you use to go from the oval openings on the smoke unit to the exhaust openings in the roof of the F3 shell?

Joe, send me an email.

I hope I got this right this time.As per your recommendation I just used JB Weld to secure a brass fitting into the opening of the TAS smoke unit I have installed in the chassis of the MTH F3 and am waiting for it to harden.Just in case that does not work what are you asking for the smoke unit you have with the manifold installed and how can I pay you if interested.