So the gentleman at Dallee is irritated with me because I've called 3 times with questions - I've got $500 wrapped up in these 2 engines and boards and want to make sure of the connections before I smoke them by accident. Only on the 3rd call did he understand I don't have "O" gauge but have "S", and on the second call I believe he played some sort of "cuckoo cuckoo" tone when he thought I'd hung up. "These units have been around for 40 years" "if you don't understand simple electric ciruit" "I can't be expected to know every kind of engine" etc. I don't want this idiot fired, I want him to understand he's not very good at his job - interacting with the public - and improve.

So rather than be insulted once again, I've come to the wise folks here.

I didn't understand that both motors run at the same time. I don't have series motors, I have 2 DC motors. There are 4 wires going off to each truck plus on the front truck 2 wires for the old Christmas style bulb headlight. Of the two sets of 4 wires, one red and one black go to the motor, once black goes to the rail pickup, and one black wire seems to be chassis ground, being connected to the truck ahead of the coupler.

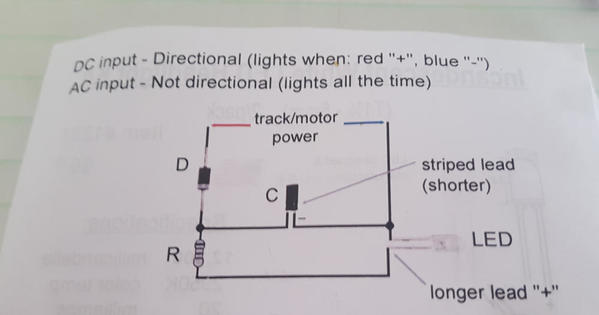

The Dallee has 6 pins 1&2 motor brush 3&4 track power 5&6 field

Since I have DC motors I just jumper 5&6 together. It would seem that I can connect the two motor leads from the two trucks to pins 1&2 either in

parallel (two wires on each pin) or in series ( one wire each pin, twist one wire from each motor together: either way, check for wheel direction by

putting engine one side and running with a jumper wire on the rail pickups, there is one rail pickup for each rail - one goes to pin 3 and one to pin 4. I should use these two leads -track power- to power the headlight ... ?

WHAT I DON'T GET

So what are the two remaining grounded wires that are connected to the truck ahead of the coupler for?

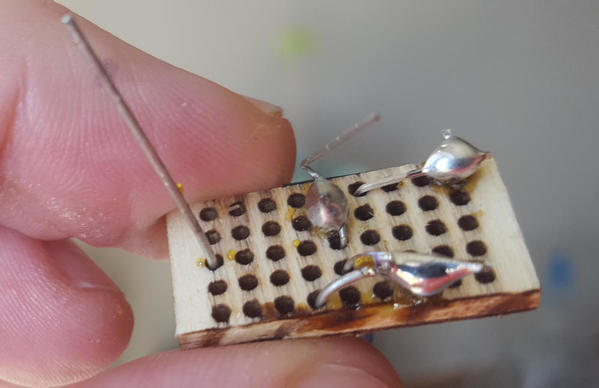

![20171014_154319[1] 20171014_154319[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/75199724070428520/filePointer/75340558592905172/fodoid/75340558592905168/imageType/MEDIUM/inlineImage/true/20171014_154319%255B1%255D.jpg)

![20171014_154319[1] 20171014_154319[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/75199724070428520/filePointer/75340558592905172/fodoid/75340558592905168/imageType/SQUARE_THUMBNAIL/inlineImage/true/20171014_154319%5B1%5D.jpg)