How about a "Smart" 21st Century Diesel Maintenance Facility Building?

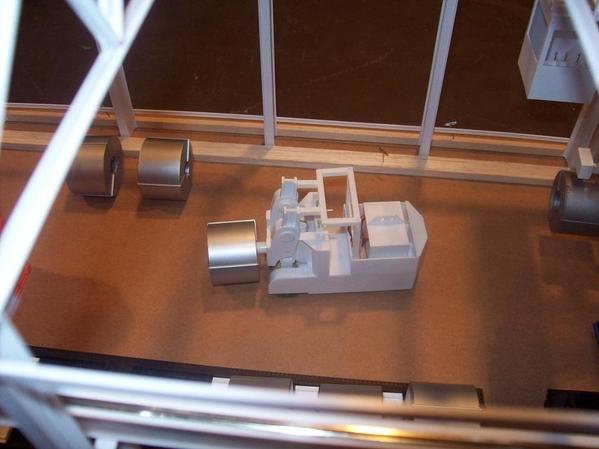

Technology and Innovations have always caught my eye. That said, I would suggest that Lionel produce a "Smart" 21st Century Diesel Maintenance Facility Building.

Legacy features:

1. Open and close the doors with Cab-1 or Cab-2.

2. Turn exterior and interior lights on or off with Cab-1 or Cab-2.

3. Enter Id’s into Legacy Cab-2 what Diesel or Steam locomotives are assigned to their scheduled maintenance and have announcements from the Maintenance Facility or Roundhouse when the engines need to be serviced. “Engine 1988 Scheduled Maintenance today track one”, kind of like a Locomotive Maintenance Management System. The Service check could be programmed for 30, 60 or 90 days. This would make for a great reminder to look your engines over for traction tire issues, lubricate gears, check for loose wires, and a general maintenance check just like the real deal. If you wanted to service all your engines in 1 session, then you could enter a code that would make an announcement of all your engine ids one at a time every 5 or 10 minutes until you have acknowledge the engine has been serviced. At the end of the day you could enter a code that would check all the engines in inventory that have been serviced and announce “All engines serviced next scheduled maintenance in 30 days”.

The Maintenance Facility could even make announcements for staging your Diesel or Steam locomotives for sand, water and fueling. “Engine 1982 Track two clear for fueling”. A two stall modern building would look fantastic. A roundhouse would be colossal!

Regards,

Swafford