I have a volt/ohm meter but when tracing an electrical problem several months ago I found, with help from folks on this forum, that a lighted car enabled me to pinpoint where a power feed drop connection had failed. So I’m wondering what other techniques/tools are needed to diagnose electrical problems?

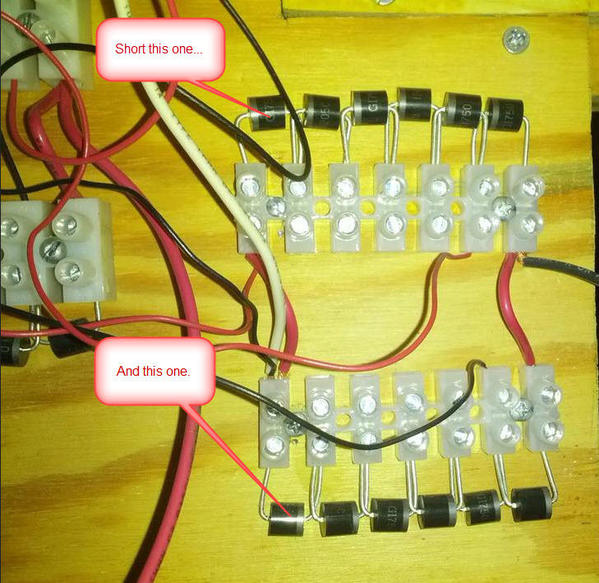

Obviously, what is prompting this question is that a problem has cropped up. I’m using conventional cab control for my layout (about 300' of track), eight insulated blocks with SPDT toggles for each block switching between the left or right handles of a PW ZW. (I use a second KW transformer for switches & accessories.)I also recently wired in two diode ladders into the circuit for whistle/bell control. I’m detecting significant difference in train speed as well as passenger car illumination between the two handles of the ZW and my suspicion is pointing towards the diode ladder. The ladder for the right handle has 5 diodes pairs per side and the one for the left handle has 6. (I used Dale H's & Gun Runner John's circuit & instructions). It’s such a difference that a 6-car passenger train slows down to a crawl when controlled by the left handle yet when I switch to the right handle, it speeds right through and the car illumination brightens.

So I have two questions:

- Could the one diode pair difference in the two whistle/bell controllers account for such a speed difference when the same train is controlled by the different sides of the ZW or should I be looking for a different culprit?

- My volt/ohm meter does not show any significant difference in voltage when toggling between the left and right handles. It’s not a very expensive meter costing less than $7 (analog) so I’m wondering, do I need either a better meter or some other tool to diagnose this problem and what other tools or equipment do I need for trouble-shooting in general, either now or in the future?