This is long but may help you decide on hand laid or not.

I have been building my layout’s track using Fast Tracks (from now on referred to as FT) components. I lost my last layout to a fire and had to start from scratch. I wanted to build it in O standard and as I was in On30 before the fire and was able to salvage some locomotives and rolling stock, some On30. A back woodsy theme dictated code 100 and 70 for the narrow gauge. I looked at ME track and turnouts in both scales. It seemed very pricey especially when I would need custom made turnouts in O and On30 (except for #5). After a lot of thought I decided to try the Fast Tracks system and went “all in”. (remember, the jigs bring good $$ on eBay when you are done)!!

I realize hand laying track is not for everyone but if you are at all considering it I urge you to read on and see how FT products and some of the tricks I’ve learned over the past 7 years can make it a less daunting task.

The FT method consists of jigs, 3 foot rail sections, PCB (printed circuit board) and wood ties. The rail is soldered to the PCB ties which holds everything together. The ties provide the additional support for the rail and receive the spikes further holding the rail.

I purchased jigs in O standard (code 100 branchline) of 36”, 40”, 42” and 48” curves as well as straight and # 4.5 and # 6 turnouts. In On30, I purchased (code 70 branchline) #4, #5, #5 wye, # 6, and # 6-3 way. Also a straight and curves of 22”, 24”, 26”, 28”and 30”. I mention all these because had I to do it again, I would not have purchased so many different radii jigs. The turnout jigs (for me anyway) are a must as they allow a fine working turnout to be made over and over in about 45 minutes. Get the frog and point tools as well as they save a lot of time. I’m using light code 100 and code 70 as I am modeling an old, back woodsy outfit. Also, I think the smaller rail makes the tighter curves I have look broader.

As to the curved track I would still get a jig for 36” (O) and 22” (On30) as this is tightest used radius and it is critical to have it consistent to avoid derailments. You can also save the cost of a Wye jig as I made this one using the left and right sides of a 4.5 O scale turnout. It was not a fast as using a jig, but I only needed one so I got to see what pre-jig turnout construction was all about. Jigs are much easier!!

Here’s how you can do more with less:

Here’s how you can do more with less:As I started laying the O standard track, I used to make an easement for a 40” curve, for example, by using the 48” jig to attach about 4 ties, then the 42” for the next 4 and then down to 40” and then back at the other end. I then found using FT sweepsticks and a couple of track gauges after soldering only the inside rail of the curve to the PCB ties in the jig gives you much more flexibility for easements and variable radii curves. You can also make any curve you need to fit your situation this way using track gauges with the one rail soldered. I find this results in much more natural looking track curves and is a lot faster. Except for the accuracy needed for minimum radii you could actually get away with just using a straight jig.

Track and roadbed alignment: what I’ve learned.My sub roadbed is what used to be called ½ inch plywood (seems to be all different measurements today!)with homasote on top. I use cork roadbed but do not like the commercial stuff as it’s too thick. I buy rolls of 1/16th inch cork at Michaels, Ace or wherever I can get it on sale and cut it into strips 1 ¼” wide, half the total width needed (10 scale feet) with my power miter saw.

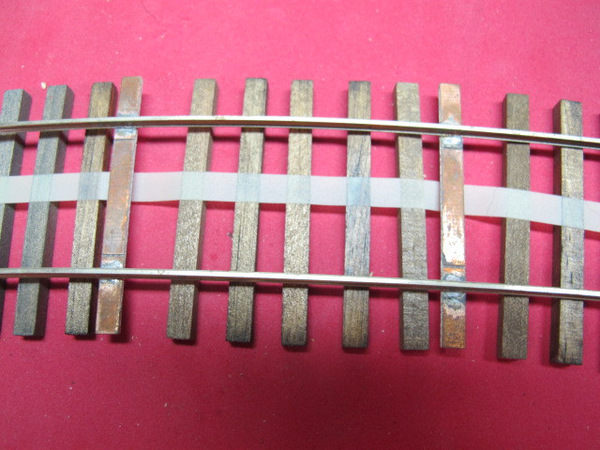

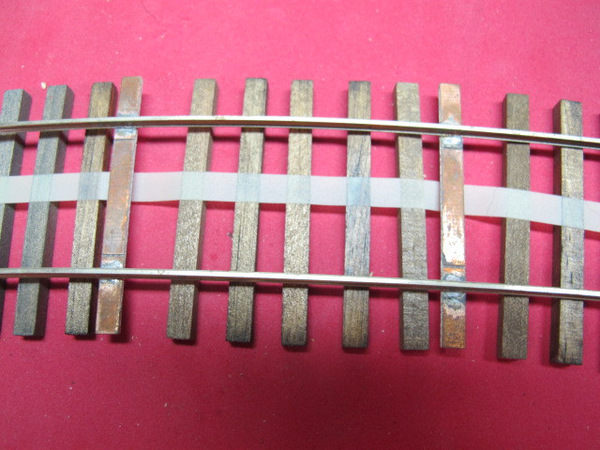

The basic premise of the FT system is soldering NS rail to PC board “ties” for alignment and strength. The PCB ties are spaced at the same spacing on all their jigs and tie racks of the same type, i.e. Mainline, Branchline and Siding (in O). I use Branchline which works out to 5 wooden ties between every PCB tie. In theory one loads up the “tie rack” with wooden ties, leaving out every 5th tie for the PC tie, then presses some masking tape to the tops of the ties. You then pull the whole strip out and place it on the cork you’ve laid down on the homasote and then set the rail and PC ties down onto the wooden ties and glue or spike. Easy, right? Well for straight track it is because a straight line drawn with ruler is always straight and everything will line up fine. The only straight track I have is in my small 4 track yard at one end of the run with the turntable, fuel and water facilities and enginehouse. The rest of the layout has curves. The problem comes because of this basic premise. No matter how carefully you measure and mark it is nearly impossible to get the wooden ties lined up with the PC ties and the edge of the cork roadbed and everything centered under the rail, all at the same time. The masking tape is not that flexible and it also blocks your view of any centerline you have. I’ve tried thin masking tape, plastic electrical tape and nothing seems to help. As you bend the strip of ties to follow the curve, the ties lose their spacing to the PC ties. Using slow setting glue for the wooden ties allows some time to monkey around getting everything lined up, but it’s very time consuming. Note the spacing of PC ties and wood ties and how in the last photo it's gone awry! See below:

I have completely scrapped this method-too time consuming.

I now do it this way.When you first read this it will seem as if I’m doing everything backwards to how it should be done. Keep an open mind and follow along to the end and you’ll see there is a "method to my madness". Do not lay your cork or Homasote roadbed yet. With this method it comes second to last.

You will notice in O scale the PC ties are thinner than the wooden ties. Per FT instructions once the track is ballasted that disappears which is true but I’ve found a better way to do the whole process. I believe in HO and N scales, like On30, the PCB ties are the same thickness so you can skip this next shimming bit.

I cut 3/32 x 1/4” bass or balsa wood strips into tie lengths. I place the PCB ties in the straight jig and solder both rails to the first tie at the end of the rail where it joins the last piece and then solder only one side of the tie for the rest of the 3 feet of rail. Once removed from the jig I then score up the underside of the the PCB ties with rough sandpaper and use CAA (use only good quality super glue) to attach the shim ties to the PCB tie. For HO N and On30 solder the single rail as above.

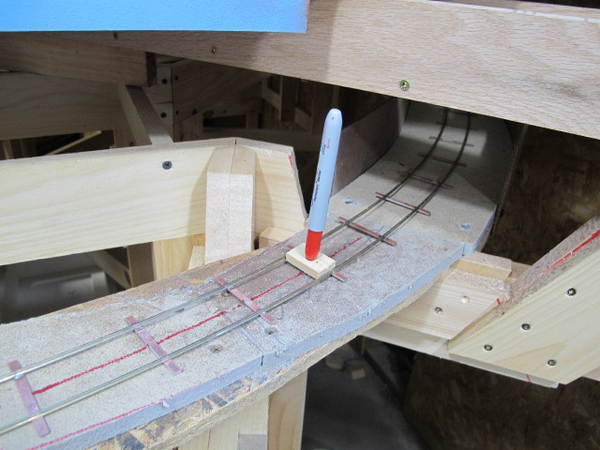

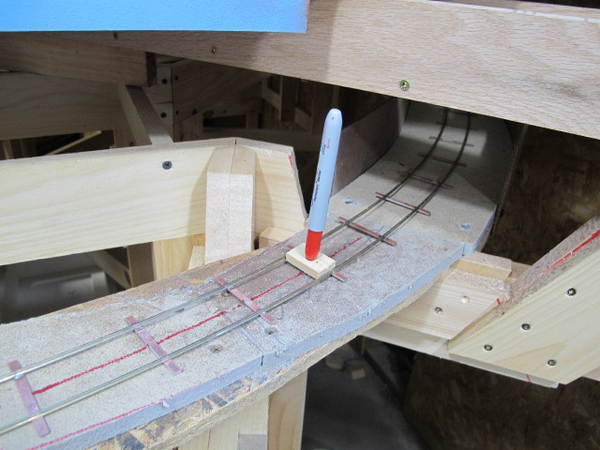

You are now ready to start laying the track. You will need a lot of push pins to hold everything in place as well as your soldering equipment and track gauges. Lay your rail down where to you want it. You will notice you can bend it as you see fit. I you want, you can align it with sweep sticks but I prefer to eyeball it using the sweep sticks only to prevent it getting too tight. Once you have it down the way you want and it’s secured tightly with push pins on the ends of the ties (wont interfere with the track gauge and center line jig) use your track gauges to align the loose rail and solder the rail in place. Continue along until you have maybe 8 to 10 feet done or come to an area that needs a turnout or crossing. Leave your ends long. Now take a sharpie and mark the centerline of the track. I use a jig with a centered hole.

Once you have the centerline drawn, pick up the track as its time to add your under ballast roadbed. I use rolled cork 3/16th thick cut to size while still rolled up on my miter saw.

Now the fun part, laying the sub ballast road bed. I have found Weldwood water based contact cement works very well and doesn’t stink up the whole house and make you high.

My cut cork strips are 4 feet long. I pin the very ends of a few to a long board tightly and spread the cement evenly with a throwaway foam brush. Now go to the layout and spread the glue over your centerline just a bit wider than the cork. In 20 minutes you can lay down the cork. Remember this is contact cement so you need to get it down in the exact location it needs to be before applying and using a lot of pressure. If you make a bobble you can pull it off and re-align it now. On curved track I find putting down the convex piece down first. I tip it and lay the very edge along the line working my way around slowly then patting it down away from center until it’s all down. Now seal it does tight with a wall paper seam roller. Do the second piece the same way tilting the edge down to meet the piece already down at the center. Again once aligned right seal it with the roller. If you have a major goof (remember all the cork gets hidden by the ballast) you’ll have to cut that piece out and put in a patch. This is sooooo much easier than using craft glue and pins and I have completely scrapped that method. Using the contact cement it stays perfectly flat and is ready to sand smooth as soon as you’ve used the roller on it. I would suggest you try this method with flex track and assembled switches.

OK, go back and get the rail you’ve soldered together and place it back on the cork. As you used the track as a template it will fit perfectly. Once you’re sure of the alignment, its time to fix the track to the cork. With O scale and wood shims under the PCB ties I just run thin CAA at the junction of the cork and the wood on both sides of the ties and in 20 seconds it’s glued fast. With non shimmed PCB ties you have already scored up (this is important as the CAA needs some “tooth” to grip well), I like to use a medium CAA and pick the tie up and run a bead of glue in the cork and then set the tie down into the glue. As medium CAA is not instant set I like to weigh it down for a couple of minutes. The next and last step for now it to place a wooden tie in the center in between the PCB ties. I use Aileens Tacky glue. (the best there is-available online or at Michaels craft store). With 0 scale branch line there are five wooden ties in between the PCB ties. If your rail requires 6 ties, I would space out 2 in the center. Once the glue has dried, spike these ties in place. Using this method, these are the only spikes you will need to drive in your track. With my O gauge track the rail is anchored every 1 1/2 inches which is plenty to hold it in place….I cannot move it side to side at all. Spiking the rail to the ties is the most time-consuming and, to me, boring part of hand laying track and one of the biggest reasons people give up on it. Cutting this down to a minimum has made all the difference to me. The proto48 and proto87 guys out there, I salute you!

Your track is ready to use now so you can test everything for alignment and smoothness.

In the below picture you can see the rail and ties prior to adding the center wooden tie in the middle and with the center ties on the right.

Here’s what it ends up looking like ballasted and painted.

Turnout control:

I use Caboose Industries HO scale high switchstands which I find exactly correct in O scale. To control frog polarity I attach a micro switch under the switchstand with an extension up through a hole that is activated by the sliding bar of the stand. See video attached:

http://youtu.be/5zF3cW_MHFgStaining Ties:

I hate the smell of Minwax Stain and it takes forever to dry so I use a homemade stain using black and dark brown India Ink in 92% alcohol. Do yourself a favor and wear latex gloves! I mix up about 4 different shades in those old rectangular plastic salad containers you get your “Spring Mix” in. Dump the ties in and swish around until they are evenly coated and colored to your satisfaction. You need to play around with the ink/alcohol ratio so I start with just alcohol and add ink until I get the right opacity tested by dipping a bare tie in. Do the same with the colors-mix the brown and black to get some variation. I use an old sieve to pull the ties out and shake off as much of the excess stain as I can. They dry faster and you stain more ties per box. Dump them on newspaper with couple of layers of paper towels (no, NOT your i-pad, Stanley!) and spread them out so they are just one layer. I then run a wad of paper towels over them rolling with a back and forth motion to get the excess dye off. They should be ready to use pretty quickly. Since writing this in 2014, I have discovered Minwax water based stain.

Like the water based contact cement it is very low odor and 1 small can goes a long way as you need to thin it a lot with water. I use it the same way as the idea ink dye. Wear rubber gloves, please.

Painting the PC ties and rail.

I pour some Polyscale roof brown or Tamiya medium brown into 3 small cups and add a little black to one and white to the other and mix, then brush these shades on the PC ties of assembled rail. On the rail I use Micro Lux rail brown in acrylic.

Ballast.

I make my own using a a product they have up here used on the roads called hard pan. It is a little big for HO and especially N. Before this I used to used sand strained different sized sieves and color it with my trusty sanded grout and think one could use this for HO. For N i wonder if sanded grout by itself would work. Here’s a closeup of the ballast:

That’s about it. I have found the Fast Tracks system to be of the highest quality, easy to use and they are delightful people to deal with. Like with everything, you learn tricks as you go along.

A few musts:

You should use Micro Engineering rail as others will not fit the slot in the assembly jig properly. You must use a non acid flux for soldering the rails or wash off the rail and PC ties with soapy water after or you will get a lovely green Patina on the rail and ties and the paint won’t stick to the ties or rail.

You must wash out your jig occasionally with a stiff NYLON brush so everything lines up correctly.

You must use a good quality solder and preferably non acid flux. I prefer my resistance soldering station as the tweezers heat both sides of the rail base quickly.

Have fun and now go build some track!!!

Peter

Like the water based contact cement it is very low odor and 1 small can goes a long way as you need to thin it a lot with water. I use it the same way as the idea ink dye. Wear rubber gloves, please.

Like the water based contact cement it is very low odor and 1 small can goes a long way as you need to thin it a lot with water. I use it the same way as the idea ink dye. Wear rubber gloves, please.