Replies sorted oldest to newest

There are differences of opinion on this but it would seem that the star wiring will give you the best in balanced power as well as being able to localize and troubleshoot power losses or other problems. A single T.I.U. would be sufficient for a layout of this size.

Legacy/TMCC works well with most wiring systems.

Do you have a power supply yet? I agree with c.sam.

You can even use the same power supply on different tiu channels to increase the track signal range.

What c.sam said! And FWIW, I am not all that experienced, but from what I have read here DCS seems to be the most fiddly as far as wiring. Although many have reported good results with many different wiring methods, many others have reported problems.

With that in mind, I will be building a layout soon and plan on following the DCS recommended wiring methods using star pattern and blocks with one power drop per block. Will be using separate power supplies for turnouts and accessories. I'm using Atlas track & turnouts too, have a DCS system and Legacy is on order (will have it if they ever ship).

I'm starting out a bit smaller than you, probably about 6x16 or 8x18, but planning to keep adding on as budget permits. Also want to do the wiring so it can be easily added on to.

To add a little more: Have purchased & will be using OGR's #14 & #16 wire from their online store for all my track power.

My layout has Star wiring for DCS based on Barry Boskowitz's DCS Ogage Companion. Track length is in excess of 300 feet, and the DCS signal strength is 10 in all locations including single end sidings.

Power wire feeds are all twisted pairs of AWG 16. All connections are sodered or screw terminals with the wire ends tinned because these are more reliable than speed nuts and clinch type connectors.

Avoid bundling power feed wires with wires connected to solenoids and signal devices. Keep the routing neat, and label the ends of all wires with masking tape.

OK, I am not the perfect wiring guru.

I had a 11 foot by 23 foot Figure 8 with wyes across the middle and 5 dead end sidings.

I ran DCS and TMCC on the layout. DCS used 2 channels fed by 2 100 Watt bricks.

I had all the sidings isolated and fed from a connector block through toggle switches, but I rarely turned them off.

I powered the main at both ends and had no blocks in it.

Did this cause DCS issues? Yes, 2 places roughly in the middle between the power drops had poor signal.

The trains ran through them anyway !!! If the whistle was blowing when they hit that area, it kept blowing until the y left the area.

Big Deal? NO.

So yes, DCS needs more attention to the wiring for perfect operation but it is not really that picky.

Also some Modular clubs have used DCS with BUSS wiring. Yes, it needs lots of Susan's Filters but it works, and those filters are CHEAP.

Have Blocks, One power drop per block with a filter at the connection and you will be fine.

/End Soapbox/

edited for spelling and format

I know one person who did it that way and seems to be OK. Maybe he will post.

In my case, I followed the star-wiring, as follows . . .

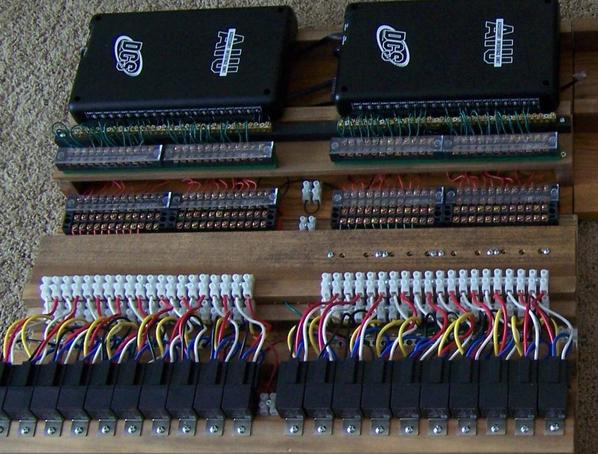

My layout occupies about 80% of a 33-ft x 38-ft room. It has 900-ft of Atlas track, 45 Atlas plus 12 Ross turnouts. I have two DCS TIU’s with five AIU’s, and a Legacy base that is connected (one wire) to just one of the outside rails at one end of the layout. Two Z4000’s supply power to one of the TIU’s, and a ZW-L supplies power to the other TIU.

I have about 20 (haven’t counted after recent additions) ‘wall-warts’ (5vdc, 12vdc, 12vac, 14vac, 18vac) scattered throughout for powering accessories. These are plugged into remote control outlets, as are the three main transformers. I have a TW transformer dedicated to run the Subway train, which is conventional. The ’L’ train, on an independent loop, run with DCS and is programmed to make stops and announcements.

Because of the location of the stairwell, the control center is 120-ft from one set of a TIU with three AIU’s, and 60-ft from the other TIU with two AIU’s. Since the initial wiring, I have rerouted some of the wiring from the control center up the wall in a PVC pipe, across the suspended ceiling, and down another PVC pipe, which is behind a structural support post. This cut the 120-ft run to 70-ft.

From the transformers to the TIU’s I use 12AWG wire. Initially I used 12-2 wire left over from finishing the basement. Later, I switched to stranded 12AWG wire because even though a bit more expensive, it is much easier to route. Four of these pairs of wires are 60-ft and the other four pairs are 70-ft long

From the TIU’s to the distribution blocks I use 14-AVG stranded wire. These eight blocks, each of which supplies power to six track sections, started out as regular terminal strips. I then changed them to relays modules, which allow me to turn any of the track sections on/off with toggle switches on the main control panel. The four 14-AWG pairs from each TIU to the terminal blocks or relay modules range in length from 8-ft to 12-ft long.

From the terminal blocks or relay modules to the track sections I use 16-AWG stranded wire. I make the hot and common connections to each track section. These range in length from 6-ft to 12-ft long.

I have no problems with DCS, other than the familiar “Engine Not On Track” and similar messages when I try to run a locomotive that I have not run in a while, but this is easy to fix. Legacy runs perfectly, but I had to run a ground wire between the upper and lower levels for a stretch of eight feet. Interestingly, there are over 100 feet of two level tracks, including sections where there are six tracks over six tracks, and only the one short section required the ground wire.

If you have any specific questions, please feel free to email me.

Good luck!

Alex

Was starting to wonder if each main having it's own buss that was wired to it's own TIU channel might be a reasonable compromise. Just looking for opinions on how you all do it for reliability before I go much father. Thanks.

I think it may be. I know that having tooo many short blocks is not a good thing and you're better off with one long one. What's the best length is the question... I'm guessing anywhere from 30 to 40 feet, Trouble is... every layout is different.We have about 7 scale miles of track with 4 tiu in super. We used Barry's wiring suggestions with a few exceptions... Actually when dcs first came out our first big layout was buss wired and worked reasonably well.

One way to to find out.. hook up a loop.

We use Gargraves track and Ross Custom Switches. We wired it using the DCS preferred method "STAR" pattern, with each block being 10-12 sections of track, and 1 power drop per block. If you run multiple drops per block, you will get duplicate commands from your DCS remote, not always, but it will happen. (Meaning for example, with 2 power drops in a block, when you hit the soft key for a forward horn signal which is 2 quick blasts of the horn, it will do it twice, because the engine received the signal twice, one on each of the power drops)

Well for the most part Ross switches can be bought "Ross Ready" which means they are wired with "jumper wires" underneath the rails of each switch. That simply means that each switch is wired so that power is running through the entire switch with one feed on either of the 3 legs. We bought our switches and ran the jumpers ourselves to make them flow power all the way through. I'm sure you could do the same with the Atlas switches.

Those filters are used to "enhance" the DCS signal, not to stop multiple commands. Many people who use the newer TIU's with the most recent software edition, are not using filters. We have 2 TIU's, Rev L, and don NOT use filters or light bulbs for enhancing the DCS signal, and we still get a 7-10 signal throughout the layout.

I do have an older TIU, from several years ago that has never been upgraded, and I need the light bulb to get the 9-10 signal on my overhead loop in the bar/gameroom.

I haven't started building yet, but yes, I am planning on mounting MTH terminal blocks in central locations and then feeding track blocks from there. Was thinking of starting with 2 channels and adding on from there as I add to the layout, TIU powered separately with a Z-500 I have from an MTH set.

As for the Atlas turnouts, I was planning on using jumpers to connect the switch legs. I'm going to have 2 loops connected by turnouts and the loops will be isolated from each other. Was also going to ask here before finalizing my setup. I have quite a bit of track and the OGR wire & a bunch of other stuff, but no turnouts. Probably won't be purchasing any turnouts until next month, so I have not had a turnout to really examine yet.

Peter,

I insulated the rails to make sure that the blocks were isolated from each other.

Another aspect you should consider is block occupany detection, perhaps for future enhancements to your train. When I first started, I insulated all three rails of each track section, but somewhere along the way I started insuating the center rail and just one of the outside rails, and in some cases just the center rail. I cannot remember why I did this. Lazy?

In retrospect, now that I am 'computerizing' the layout, I wish I had insulated at least one of the outer rails of each track section throughout. BTW, the isolated outer rail provides the one of the easiest and best occupancy detection schemes, in case you are interested.

Glad to help (or at least try to . . .)

Alex

I also have a double track mainline. I use four conductor 12 gauge trailer cable plus a 10 gauge common ground. I have leads to every track section. Two of the conductors are used for the two main lines. The other two are used for switches and accessories. It works very well for my TMCC system.

PJB, May I ask why you are planning to replace you stranded wire with solid wire? Thanks, Pat B.

PJB, May I ask why you are planning to replace you stranded wire with solid wire? Thanks, Pat B.

I'm curious as to the reasoning here as well. Since it's not going to make any difference, it seems like a lot of trouble for nothing! ![]()

![]()

Peter, I am sure that will not make any difference. The statement is made in reference to the tap wires and it says that solid wires "can" be used. I would believe that if it made any difference at all stranded wire would be preferred over solid wire of the same wire gauge because of the skin effect at high frequencies. I am just concerned that you would go to the expense and trouble of rewiring for no benefit. Pat B.

Really starting to consider the bus wiring option. I have the OGR stranded 14 AWG for all my power drops, and I really like this stuff. But don't think OGR sells it in 12 AWG. Newbie question - any recommendations for 12 AWG? Or is any old 12 AWG sheathed speaker wire fine? Thanks again.

I'm sure there was a misinterpretation of what was said on that link, stranded wire is fine. ![]()

"can be" is the operative phrase. They also "can be" stranded, and it'll work fine. ![]()

Newbie question - any recommendations for 12 AWG? Or is any old 12 AWG sheathed speaker wire fine? Thanks again.

Here is what I used for the Bus wire from Waytek Wire:

12GA 2 Conductor Jacketed Wire

Email me if you have any questions.

For the record - I am being quoted above in relation to discussing "wire taps." First, I don't work for the CIA, so I don't wire tap. Second, I'm not electrically savvy enough to have made that comment.

Peter

Mr. Broskowitz was kind enough to call me and patiently walk me through the wiring considerations – thanks Barry. Then reviewed this thread, my notes from my call with Barry and the underside of the Atlas turnout for a while. Think it finally sank in. For other novices struggling with this, I think it basically breaks down like this:

- The three center rail legs on a turnout are electrically connected only by the jumper wires (long wire between lead center rail leg and the straight center rail leg in the Y; and the short cross-over wire between the two center rail legs in the Y – collectively, “jumper wires" ). Remove these two wires and all three legs are electrically isolated from each other.

- Atlas obviously believes the turnout wire gauge is sufficient. From various real-life experiences posted here and elsewhere, however, many hobbyists feel this isn’t necessarily the case. Therefore, many hobbyists decide to do one of two things: (a) replace the wires with more robust wire; or (b) the more common approach is to power the turnout from all three sides. But powering the turnout from all three sides will run afoul of the DCS “one drop per block” philosophy (unless two of those drops are getting power from a source NOT running to the TIU). Basically, to adhere to the DCS philosophy you must do one of two things:

(a) for a two block scenario, either (i) replace both “jumper wires” (with more robust wires), put a plastic track connector on the leg going to the “other” track block; or (ii) alternatively, just replace the one “jumper wire” (with a more robust wire) for the two turnout legs in the same block and simply remove the short cross-over “jumper wire” between the two Y center rails (and DON'T use the plastic track joiner, given the electrically isolated leg must rely on power from the "other block"). In either case, this will electrically isolate one block from the other. And then you simply rely on the TIU power drop and the more robust “jumper wire(s)” to power everything.

(b) For a three block scenario, remove both “jumper wires” and you have three electrically isolated legs that would be powered by each track block’s discrete TIU power drop.

Having said that, I am curious what your actual experience is when you don’t adhere to the DCS “one drop per block” philosophy and don’t use filters and other gizmos? Basically those who might star pattern but use three drops for each turnout, or route two of the turnout power drops to an alternate power source, or buss wire and put power drops every so many feet, etc.

Peter

I have a 12 x 28 conventional layout. I have 4 loops, lots of accessories and lights. I ran a #8 common wire bus under the entire layout and use it for everything. The other wire bus for the loops and accessories is #14. A separate bus for each loop and separate buses for 12V, 14V and 16V accessories. Half way around the layout each bus is connected to an on/off toggle switch so that I can isolate half the layout when trouble shooting.

DCS and Conventional Wiring scheme:

On my concept layout I use shielded pairs of 18 gauge wires which are attached to each track block (connected in the middle of the block). This cable is the same used for security systems. My block lengths are no longer than 6 feet in length.

Each block is controlled by a separate relay. Each block has individual 3A circuit breaker protection. Block control is by using a toggle switch panel or my TIU/AIU using a 12vdc wiring scheme.

All turnouts use AUX power and are controlled by a relay. Turnouts can be operated using pushbuttons or my TIU/AIU. The turnout motors are protected by current limiting and separate fuses.

I use a circuit breaker on each TIU output. I also use a circuit breaker on each TIU input.

Track power is obtained by two MTH Z-4000 transformers. One Z-4000 is wired for conventional operation only. The second Z-4000 is wired for DCS operation only.