Ok I did hear back. I got a very nice reply from Meghan who apologized for the delay she was waiting for Mike to get a more definitive answer. I appreciate the response and hope you find it useful

My question...

Good day. Based on a thread on the OGR forum, does other manufacturers smoke fluid void a warranty repair on a Lionel smoke unit? I understand, as I would expect, Lionel recommends the use of their premium fluid but is there a penalty if a smoke unit goes bad while using another fluid?

From Lionel...paraphrased

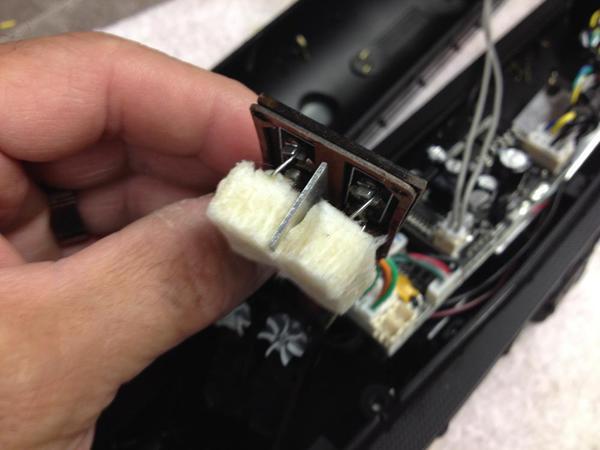

They do consider issues with smoke units from use of other brands and overfilling as abuse and misuse of the product resulting in a non warranty repair and would not be covered. Lionel highly recommends the use of their premium fluid as their products are designed to work with them. They have had many instances of having to clean circuit boards and "gunked" units from other fluid brands which is time consuming and tedious to the techs.

End of paraphrasing.

So what I got from this is yes using other fluid could cause you to loose a warranty repair status. I imagine if you smoke unit fails and you use Lionel smoke fluid you'd be fine but may not be if using another brand regardless of what the failure was. I also gather that if they find smoke fluid, regardless of the manufacturer, on circuit boards it would also result in a non warranty repair.

What does this mean? I'm reading it as if you expect Lionel to repair your engine under warranty your best bet is to use Lionel premium fluid to Lionel's recommended specs. Of course this is entirely up to you.

If you don't like the answer I encourage you to contact Lionel. I imagine there has been some costs involved which may have to do with their policy. For engines under warranty I'll stick to their recommendation. I don't want to pay for parts or repairs that can be avoided. Again, if you don't like the answer I encourage you to contact Lionel. Maybe Mike will jump in here. I hope I represented the response accurately.