I have a 3rd Rail 2-10-4 CP Selkirk. It doesn't pull nearly as heavy a car load as my MTH CN 4-8-4 though. Getting it to pull six GGD heaveyweight cars is a bear. No trouble at all with the MTH. And that's on flat track. I hope to have a 2- to 3 percent grade on my layout. This loco will never carry those cars up a grade, no matter how slight. The traction tires are intact on the rearmost drivers. The motor has lots of power. It's a matter of traction. Any tricks to increase traction? Weight the body? As if there's room for any significant weights and as if it's not already a heavy engine. Make the traction tires "stickier?"

Replies sorted oldest to newest

If there's room in the boiler, add as much weight as you can. My 3rd Rail GS4 pulls all 14 GGD Daylight cars with out a problem on flat track. GGD cars heavy, and a 2-3% grade is probably going to eat up some traction tires.

Have you weighed the 2 engines to see what the difference is?

Did the traction tires get oil on them maybe, dust/grime making them slick?

I can relate when I was modeling HO some of my brass engines where too light to pull 20 cars up a 2.0 percent grade.

I would focus on adding weight. There was in article in MR many years ago on how to Balance your brass engines and add weight over the driving wheels.

Can you open it up and see if you have space in the boiler?

I would replace the traction tires too. Rubber tends to dry out over time. Do they look glazed over?

Everyone is correct. Add more weight.

If you have room to add weight, get some stick on tire weights sold at auto parts stores.

Cut to fit.

I use rubber gloves when handling them-and I'm NOT a 'Safety Nazi'!

IF that and the traction tires don't solve your issue, time to look at some other things...

Everyone is correct. Add more weight. Keep in mind that the trailing truck is a double axle, which pushes the drivers forward on the model. Rear driver/with the traction tires is probably very close to the center of gravity of the model. Model is probably back end heavy, needs weight to the front, to more evenly distribute the weight over all the drivers. My Weaver CP Hudson is "tippsy" this way. Front driver set seem to have very little weight. IMO

Mike CT

Before adding weight, be sure that the traction tires are functioning properly.

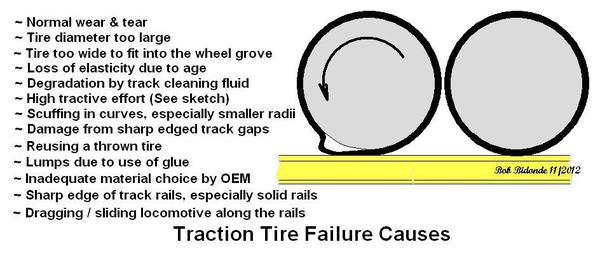

I would replace the traction tires with new ones by MTH as they perform better than all others. There is a traction tire chart attached to this post.

Be sure that the traction tires are not slipping on the drivers. I use one size smaller than the locomotive manufacturer specifies. Tract cleaning fluid and smoke fluid contamination will cause the tires to slip on the drivers as well as the track.

Adding weight to the locomotive requires more work and traction to get the locomotive up grades.

Attachments

Thanks all for the helpful replies.

The tires LOOK fine but the loco has been a "shelf queen" for several years. Supposedly it had very little running time before being crowned. I have on hand only the replacement tires originally packaged with the engine.

I strapped weight to it. An unrealistic amount of weight really, meaning I'd never be able to get that much inside it for permanent installation anyhow. Definitely pulled better. Better, but still not as well as the MTH, an engine of similar weight but perhaps spread over a smaller area too.

Not sure about getting the rod off the drivers for replacing the tires either. I have a tool, but it does not fit the recessed bolt on the Selkirk. replacing the tires looks a pretty fiddly job?

PS: Anybody using "Bullfrog Snot?" (Embarrases me to type it.) http://www.bullfrogsnot.com/howtoinstall.asp

Terry, check with Scott Mann from Third Rail/ Sunset Models. He sent me the right size tool that I needed.

Thanks, Paul.

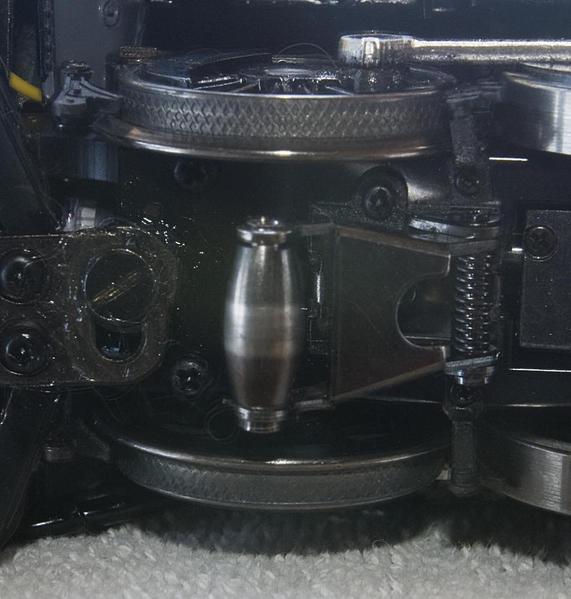

But isn't the tool the one pictured? I recently bought several engines. Three Sunset/3rd Rail, a Weaver and an MTH.

This tool came with one of them but I am no longer sure which. No matter in that it doesn't fit ANY of them??? ![]()

Attachments

There are some wheel designs that just don't have the same pulling power. The T1-Duplex comes to mind. You'd think it would be similar to something like the Northern with the same number of driving wheels, but it's not even close. This may be one of those cases. Also, if it has sprung drivers, see if something is amiss in the suspension. Could the pilot or trailing truck be exerting too much "lift" and unweighting the drivers? To test that, you can take the pilot wheels and trailing truck off and see if that changes the traction.

Something else to check, especially if the drivers are not sprung, is whether the drivers all contact the rail evenly.

As already mentioned: add more weight, replace traction tires if they seem hardened, clean rails.

When space is limited, it may be possible to reshape pieces of lead to fit the available spaces. I've hammered old .22 bullets into small shapes to fit in HO locos. Lead fishing weights of different shapes and sizes can be adapted for O gauge locos.

Something else that might help: occasionally I run a home-made rail cleaner car around the layout with very fine grit sandpaper to remove light oxidation on the rails. I've noticed on my HO layout that this may help traction somewhat by removing the glaze on the rails.

At this point I'd also look for binding, brake shoes touching drivers, worn cog drive belt and other mechanical obstructions.

Has it been well lubed? Not what it came with, but the old grease cleaned out and newly lubed?

Are the wheels spinning when you try to pull the cars? If not, traction is not the problem.

Some locomotives are geared different. Generally, all of my 3rd Rail locomotives will pull the foundation out from under the house!

We'll keep giving ideas until you solve it. Now I'm curious also.

At this point I'd also look for binding, brake shoes touching drivers, worn cog drive belt and other mechanical obstructions.

Has it been well lubed? Not what it came with, but the old grease cleaned out and newly lubed?

Are the wheels spinning when you try to pull the cars? If not, traction is not the problem.

Some locomotives are geared different. Generally, all of my 3rd Rail locomotives will pull the foundation out from under the house!

We'll keep giving ideas until you solve it. Now I'm curious also.

I have lots of questions about Sunset/3rd Rail. Like how to take the shell off? I can't figure it out.

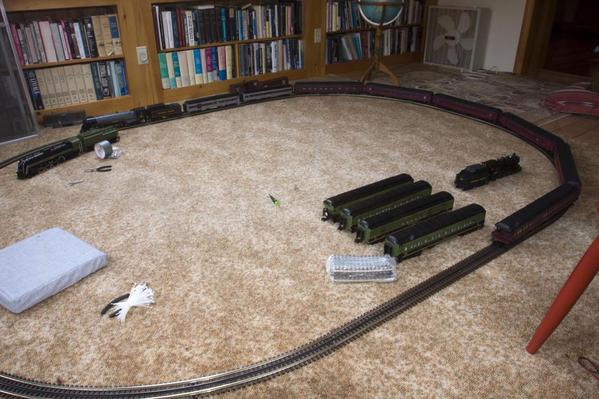

Definitely wheel spinning! If it wasn't such a poor puller compared to the MTH 4-8-4, I'd just accept it as "normal." The six GGD cars DO seem a good load. I have only a carpet loop so far and those cars stretch a long away around . . . 180 degrees. O-72 curve.

Pic attached of loop as well as a closeup of the tires.

Attachments

I have lots of questions about Sunset/3rd Rail. Like how to take the shell off? I can't figure it out.

Terry, can't help with that. Most are different from each other. Generally speaking, the shell is held on with screws from the bottom. Once you have them out, try GENTLY moving the shell off the mechanism, may require fore and aft movement. Remember, there may be delicate wires to deal with. Take your time and be careful and you'll get if off safely.

Word of advice-keep a hand under it when trying to get the shell off. You'll never know the mechanism slid out until your hand gets lighter and you hear something hit the floor. At this point, the vocabulary will embarrass a Sailor! Guess how I know?

Definitely wheel spinning!

Change the traction tires while you have it apart. Who knows how old those tires are(?). They could just be so hard they won't get any grip, which sounds like your problem.

As far as Bull Snot, I prefer to use traction tires. Just my opinion.

Let us know what you discover.

that engine most likely has sprung drivers. if the wheels with the traction tires grab too much, they will lift and you loose the grip. engines with un-sprung drivers are better for traction, sprung drivers better to look at. you choose

Most brass engines use two small screws on the back of the cab below the deck. Then one large screw above the engine truck. If you are used to diecast engines you would not think the two tiny screws are enough but they do the job.

As for slipping drivers the first thing I do is make sure there is no oil on thr drivers. I use an automotive degreaser called Prep Sol. Its safe for paint and won't attack rubber if used quickly. Wipe on then wipe off. Second choice would be lacquer thinner but you have to be more careful of paint and rubber. Lay the engine on its top and apply power to it and hold a Q tip against the drivers.

Pete

The other flanged set of drivers is front or the second set back from the front, does this set also have traction tires????

We have both the Selkirk and 6060. the 6060 is a better puller for sure . As mentioned the Selkirk has sprung drivers, if I remember correctly there is some adjustment, I was able to slide a thin piece of paper under some of the drivers between the rail and drivers. They weren't even touching the rail, The fix.???? it doesn't get run much. A beauty engine though.

Hmmm . . .

See attached image, please.

Two drivers on one side, and one on the other are "floaters" as evidenced by the paper I can slide under them. If I read Gregg correctly, there isn't much I can do about that? I thought it didn't matter anyhow as the engine only drove one axle, the one with the traction tires? There is only the rearmost axle with tires.

I love to run this engine! It's whistle is just so mournful!! At slow speeds it chuffs wonderfully too. At higher speed though, the sound seems to fall apart into cacaphony?

Attachments

The motor only does directly drive one axle. But all of the drivers move, and all should be contributing to traction.

Beautiful-looking model, by the way.

Try a little BullFrog Snot on those middle drivers, itll take up that gap and add some more traction

I have this engine and her is a easy fix> Put loco upside down and loosen the two rear screws on the plate that holds the drivers in. Take a round toothpick and shove it under the plate to raise it up. Put the toothpick on both sides to get maximum lift of the plate. Then screw down and you will get more weight on the traction tires and put on new thin traction tires that fit the slots well and do not buldge over the edges. It will pull allot more

PS if you have scratched the rear decals on the tender I can make it like brand new. email me if interested annie175@live.com

Here are a few ideas that haven't been mentioned yet. First, check the spring tension on the pickup rollers and the trailing truck, if it has a spring to hold it down. If the pickup roller springs are too stiff, they will exert a lifting force on the drivers, reducing traction. The same goes for the trailing truck. I have a brass 4-6-4 that came from the factory with a spring so stiff pushing down on the trailing truck that it lifted the rear drivers. A softer spring fixed the problem.

Check to see that all the drivers move up and down freely and that the journals are mounted correctly in their slots. I have seen journals mounted incorrectly, preventing them from moving up and down. The fact that you can slide a piece of paper under three of the drivers indicates that the driver springs are too stiff. This is very, very, common. The idea of sprung drivers is that the weight of the engine compresses the springs, equalizing the down force on the drivers and allowing them all to remain in contact over irregular track (just like the prototype). Check with 3rd Rail's service department about getting softer springs, or you may be able to carefully shorten the ones you have.

You can try roughing up the traction tires with a piece of fine sandpaper. If they are worn slick from spinning, and/or have a glaze from age, roughing them up a bit may help.

More weight might help, but that is a brute force approach that essentially overpowers the problem rather than solves it. Something is keeping your engine from having as much traction as it should - look for the cause.

If you have room to add weight, get some stick on tire weights sold at auto parts stores.

Cut to fit.

I use rubber gloves when handling them-and I'm NOT a 'Safety Nazi'!

IF that and the traction tires don't solve your issue, time to look at some other things...

The weights are made of steel. Lead is not allowed anymore.

MUCH IMPROVED!!!!

Thanks to all for their suggestions. I would like to replace the traction tires but the tool I have just doesn't seem to fit the recessed bolts holding the rods to the drivers.

Ironlake's toothpick suggestion struck me as a bit ungainly and, after I placed the toothpicks in there, the other drivers were really floating and I was not at all hopeful but . . . IT WORKED!!!

More weight is on the tires. The engine starts nicely pulling all six GGD heavyweights plus two additional MTH cars, my entire CP passenger collection. With no wheel slips at all! That's all I need it to pull. Whether it will take them up any grade at all remains to be seen. If I can't get those rods off, BF Snot may be the only alternative when the tires fail.

Again, considerable success and thanks everybody! ![]()

Here are a few ideas that haven't been mentioned yet. First, check the spring tension on the pickup rollers and the trailing truck, if it has a spring to hold it down. If the pickup roller springs are too stiff, they will exert a lifting force on the drivers, reducing traction. The same goes for the trailing truck. I have a brass 4-6-4 that came from the factory with a spring so stiff pushing down on the trailing truck that it lifted the rear drivers. A softer spring fixed the problem.

See my post yesterday. ![]()

If you have room to add weight, get some stick on tire weights sold at auto parts stores.

Cut to fit.

I use rubber gloves when handling them-and I'm NOT a 'Safety Nazi'!

IF that and the traction tires don't solve your issue, time to look at some other things...

The weights are made of steel. Lead is not allowed anymore.

Though it has nothing to do with the thread, thanks for pointing it out. I wear the gloves because the weights having a nasty coating that is hard to get off your hands. Not because they were lead...and, yes, they were the steel ones.

Sorry if I confused you.

As a technician, I work with these weights all the time with no issues with the coating but there are all kinds on the market. We even get some that are painted. There could be a issue with the coatings but I have not run in to them.

Here are a few ideas that haven't been mentioned yet. First, check the spring tension on the pickup rollers and the trailing truck, if it has a spring to hold it down. If the pickup roller springs are too stiff, they will exert a lifting force on the drivers, reducing traction. The same goes for the trailing truck. I have a brass 4-6-4 that came from the factory with a spring so stiff pushing down on the trailing truck that it lifted the rear drivers. A softer spring fixed the problem.

See my post yesterday. ![]()

hm, undersized traction tires? could it be it needed thicker traction tires than shipped. Reading the repair is what comes to mind.

So, what did Scott from 3R have to say about the traction? Did he tell you which size nut driver would fit?

So, what did Scott from 3R have to say about the traction? Did he tell you which size nut driver would fit?

I did not contact 3rd Rail. However, I DID find a 3mm nutdriver that will work. The mystery remains as to just what the tool I included an image of is for??? There is one remaining possibility. One of my engines is out for servicing . . . a Sunset/3rd Rail CP 4-8-4. I can only guess that tool will fit it. I have three Sunset/3rd Rail engines. It seems only one came with the tool? That seems strange.

So I can replace those tires now. I haven't yet done so as the engine seems to be pulling fine after lowering the rear driver axle with Ironlake's "toothpick trick."

And, frankly, replacing the tires looks like a job where some bad language will be involved? I've already used up some of my supply of that on trying to get the spring on the rear truck back into place. First thing I need to do is fashion a foam cradle for holding these things upside down while working on them.

Seems to me magnetraction is a better idea than these fiddly tires. On steel track anyway. Does Lionel still have a patent on that?

Before you modify your loco: I would make sure all of your passenger car axles are well-lubricated. Also that there isn't excessive tension on the center rail collectors for the passenger cars' interior lights. My $.02.

Terry

Welcome to the wonderful world of brass. Talk to any 2 rail O scaler and they will be able to name several go to guys to get your brass locomotive, from much higher prices importers than 3rd Rail, to run reasonably well after an extensive mechanical rebuilding. It is just the nature of low volume production by small firms who may have high employee turnover and who themselves may not stay in the train business too long. Sprung drivers sound like a nice feature but they can be a disaster if the springs and the axle loadings don't match just right. And they are often wrong.

3rd rail has come up with a pretty good mechanical design with their belt drive and they stick with it. They have some very talented designers working for them right now. But weight an balance change with every model. If you want a model of a particular locomotive Sunset may be the only game in town. You can expect it to run smoothly and get good customer service and warranty support. But if you want it to pull like a typical diecast locomotive you should expect to make some modifications to the springing and to add weight. And then you should be aware that by increasing the traction you are also increasing the stress on all the drive train components from the traction tires to side rods and pins to the motor and control circuitry.

This is a shot of a Sunset GN O-8 Mikado double headed with and MTH S-2 northern pulling 14 passenger cars on a 2.5% grade. The O-8 has to double head to handle this train. The S-2 can pull the train and the O-8. It is just they way of brass.

What a beautiful scene, Ted!

Well, I suppose I could doublehead my 2-10-4 Selkirk with my Atlas GP-9!

I mean, I could, but . . .

![]()