Updated 12/27/2013:

Got back yesterday from a wonderful Christmas visit with my parents, sister, brother-in-law and their kids in Erie, PA. We left Tuesday and got back yesterday. Didn't do any model railroading during the trip, but did get some thinking and planning done regarding the highway overpass at Crawford's Crossing (see photo below).

That's not a great photo of the overpass, it is too far away and much of it is hidden by the pipe bridge next to it and the mill power line towers. I'm planning to simulate the look with Crow River highway overpass components. This photo shows the rough placement of the highway between the mill buildings.

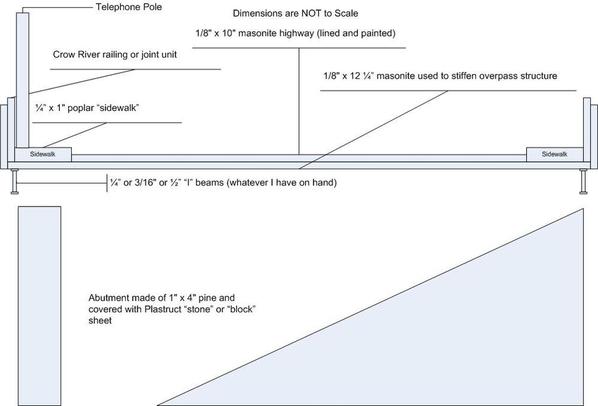

What I had been struggling with was how to organize the structure - add sidewalks, telephone poles, and the Crow River railings and joint components and have it all hang together. Plus the highway must be 4 lane and the overpass must descend from a level height of 6" (between the mills) to the module floor into downtown North Weirton. (NOTE: The drawing doesn't show the upright bridge supports and wooden block necessary to achieve a 6" clearance.). I solved that puzzle during the trip.

A triangular support made out of 1"x 4" pine board will be used to ease the descent. There will be one of these at each side of the road. Disguised screws will be attached through the sidewalk into the support. The roadbed will then be bent downward to mate with the module floor. Screws will be inserted from the underside of the module floor into the supports to anchor them and achieve the downward slope.

I'm cutting a number of wooden components (sidewalks, underlying masonite) tonight. Hopefully, I'll get to paint and scribe the sidewalks this weekend.

And the DZ-2001 buss work is still to be done. That is also this weekend, assuming real life doesn't intervene!

George