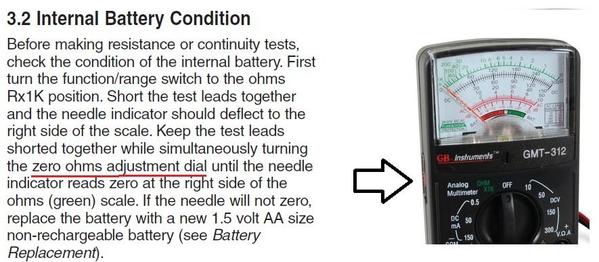

OK - I think the stars are starting to align! If the Resistance is 0.1 (x1K), that's 100 Ohms.

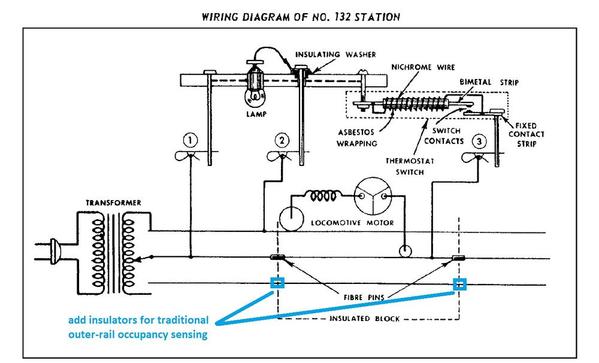

So when engine enters block , there's ~12V AC across the 100 Ohm Nichrome Wire (heater). That's a heating power of about 1.4 Watts. (Watts = Volts x Volts / Ohms). 1.4 Watts seems like a reasonable power level to warm up a bi-metal switch. And 10 sec seems like a reasonable warm up interval.

This is why the original Resistance measurement of 2400 Ohms seemed odd. That would be a heating power of only 0.06 Watts which is hard to imagine warming anything up!

Since there's 12V AC available when the engine is stopped (and the Nichrome Wire "heater" is active), the obvious solution is just hook up a 12V AC relay.

But, while 12V AC relays are certainly available, they tend to be expensive and can consume coil power on par with the Nichrome heater. This can upset the apple cart in terms of station delay timing and such depending on how much power the relay coil steals from the Nichrome heater.

So my suggestion is the Azatrax MRAPR-12V AC/DC relay. This is actually a DC relay with some components to make it function as an AC relay. The coil resistance is 360 Ohms which is several times the Nichrome Wire resistance. It will "steal" some power but I don't think you will see a material change in behavior.

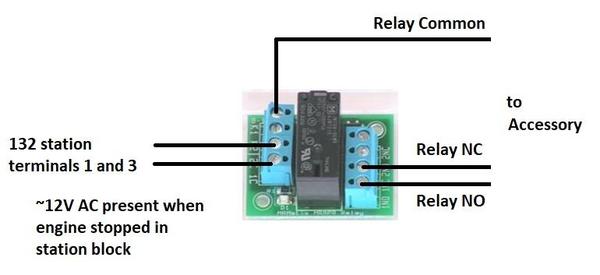

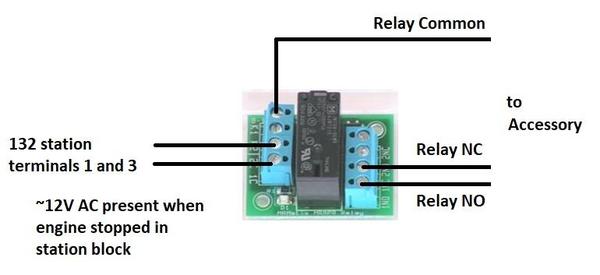

The coil inputs to the relay module would connect to terminals 1 & 3 on the 132 station. The relay contacts of the module would go to the Accessory using the "standard" Common, Normal Open (NO), and Normal Closed (NC) connections.

I realize some signal accessories (possibly including the Semaphore) might only need the Common and NO contacts. So one could ponder whether a simpler (less expensive?) relay module could be used. But in general, for signaling widgets that power red/green or up/down, you need all 3 contacts. So with shipping, I figure about $15-$20. Note the convenient screw-terminal connectors on the Azatrax module.

----------

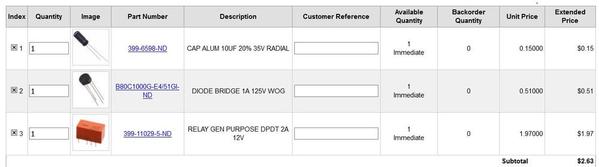

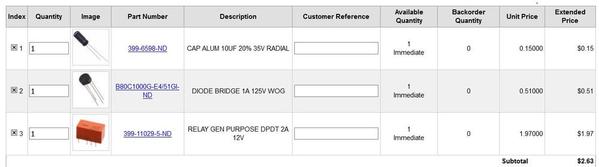

Now all that said, one could roll-their-own equivalent to the Azatrax module for half or less out-of-pocket cost but requires soldering and gathering and assembling at the component level. A bridge-rectifier (for AC-to-DC conversion), a capacitor to smooth possible coil chatter, and a 12V DC relay should do the trick. Would require a dozen plus solder connections. So less than $3 in parts cost and you'll pay more for shipping. For example, from DigiKey.com. Links purposely NOT provided as this was hastily searched.

What a DIY approach does provide is ability to tailor the parameters to the application at hand. For example, the relay above has a coil resistance of 1000 Ohms...or roughly 10 times that of the ~100 Ohm Nichrome Wire heater - hence a neglible burden.

--------

Separately, for the sake of completeness, I was searching OGR and there have been several threads about the 132 station. Apparently, if the Nichrome Wire / thermostatic bi-metal switch fails, a "genuine" replacement can run $25 or more and it would be re-furbished at that. So there have been occasional discussions about how to duplicate the 132 station stop performance. To that end it seems the direction others have taken is to use timer modules and relay modules. For maybe $5-10 on eBay with little or no soldering, one could cobble together some modules to kill track power for some settable time delay ... and then re-apply power for some different time delay (to let engine leave the controlled block) before re-arming to stop the next pass thru. Actually, this would be a DIY'ers playground; I was imagining how to sense the engine was approaching the station at high speed (high track voltage) which would disable the stopping and let the "express train" go thru. Only the "local" trains approaching at slower speeds would stop. And so on.