Train shows are really great places to meet other hobbyists, share information, and shop for bargains. Recently, I went to one of Greenberg’s Shows in Wilmington MA, just outside of Boston. While there I found an incredible deal on a vintage 1998 MTH Santa Fe F3 ABA. I was reluctant to buy it, because I wasn’t sure if it was fully operable, and since I’ve had no experience with anything other than post-war Lionel and Marx locomotives. I wasn’t sure that I’d be able to fix it if it wasn’t working properly. The seller assured me that it would work with my post-war vintage Lionel transformers – so I bought it. Initially, I couldn’t figure out what model it was, or how to make it work. After posting pictures of the locomotive to this forum, and describing the problems, I found out that it was a MTH model 30-2131-1 with Protosound, and it needed a new 9 volt battery. I discovered that a lot has been written about the best batteries to use with Protosound 1 locomotives. I also discovered that the recommended battery types are not easily found at your local box-stores. As an interim workaround, I used an ordinary alkaline 9 volt battery. So with that, the locomotive is temporarily working, and I did some performance testing to see how it would stack up against one of my favorite post-war diesel EMD “cab-unit” locomotives – the Lionel 2333 New York Central F3. But first, I am going to describe some salient mechanical/electrical features of the locomotive.

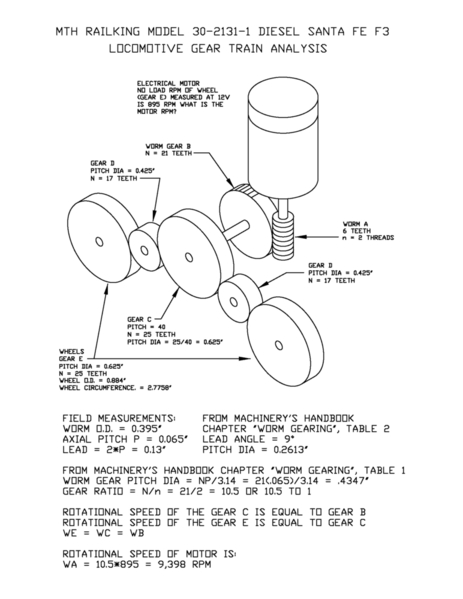

The locomotive weighs 3 lb 5 oz. The unpowered B unit weighs 1 lb 12 oz, and the unpowered, dummy A unit weighs 1 lb 15 oz. The locomotive has two die cast trucks, each with two powered axles. Four of the eight wheels have rubber tires, so it has very good traction. I could easily pull the B-unit, the dummy A unit and 3 heavyweight Lionel Madison-series, lighted passenger cars. I chose those passenger cars because they have a lot of rolling resistance and are very hard to pull. In fact, I measured the drawbar pull required to get this mashup rolling, and it was 12 oz. I removed the shell to take a look at the mechanical and electrical components. Each truck is powered with a vertical can-type motor – which I discovered is a dual-shaft, RS-365SH, brushed, permanent-magnet, 12-24V DC motor, with a brass flywheel on the top shaft of the motor and a worm on the bottom shaft. This is the first time I’ve seen one of these train motors – since all of my other post-war locomotives have series-wound, universal (AC or DC) motors. I examined the gearing and made some field measurements, and as best as I can determine, using my old, 20th Edition, Machinery’s Handbook as a reference guide, the worm has 6 teeth and two threads, with an axial pitch of 0.065”, a lead of 0.13”, and a lead angle of 9 degrees. The pitch diameter of the worm is 0.2613” and the O.D. of the worm is 0.3095”. The worm gear has 21 teeth, with a pitch diameter of 0.4347”. The gear ratio (10.5) is equal to the number of teeth on the worm gear (21) divided by the number of threads (2) on the worm. Worm gear drives are generally self-locking or irreversible – meaning that the worm can drive the worm gear – but the worm gear cannot back-drive the worm. That is definitely the case with this locomotive. Once you place it on the track, it won’t roll forward or reverse unless done with power applied to the motors. The diagram below shows the gear train.

I bench tested the locomotive with a 90 watt Lionel 1033 transformer and measured the drive wheel rotational speed using a Cen Tech digital photo sensor tachometer. At 15.5V the wheels where spinning at 1315 rpm and the locomotive was drawing 0.98 amps. At 12V, the wheels ran at 895 rpm and the motors drew 0.8 amps. Since I don't have the ability to directly measure the rotational speed of the motor, and since this locomotive has a gear ratio of 10.5 to 1, I calculated a motor rpm equal to 13,807 rpm at 15.5V and 9,398 at 12V.

Now let me describe the test track and testing equipment. I have a loop of 0-31 gauge tubular track, and the total center-rail length is 13.4434'. I have a 90 watt Lionel 1033 transformer, and I have power applied in two separate equidistant points along the line. I have a digital multimeter to monitor the track voltage. I have a clamp-style amp meter to monitor the amperage from the hot wire between the transformer and the track. For the time trial, I used the stopwatch feature of my Android phone, and timed the train over 5 laps. I tested just the locomotive at discrete 1 volt increments from 7 to 13 volts AC. Outside of this band, the locomotive either would not move or would move so fast I was afraid that I'd derail and damage it. I then connected the consist and repeated the time trials at 11 through 13 VAC. Again, the train would not move at less than 11 VAC, but when I cranked up the fully loaded transformer, all I could get out of it was 13 VAC, and the train running at 46 mph. Below is the velocity calculations and amp draw:

Locomotive Only

| TRACK VOLTAGE | Elapsed Time MIN | Speed FPM | Motor RPM | Speed MPH | Scale MPH | Amp Readings | Power Watts | HP |

| 7 | 1.84 | 36.567 | 1659.9 | 0.42 | 19.9 | 1.1 | 7.7 | 0.0103 |

| 8 | 1.26 | 53.241 | 2416.7 | 0.61 | 29.0 | 1.15 | 9.2 | 0.0123 |

| 9 | 0.81 | 83.361 | 3784.0 | 0.95 | 45.5 | 1.18 | 10.62 | 0.0142 |

| 10 | 0.60 | 112.560 | 5109.3 | 1.28 | 61.4 | 1.23 | 12.3 | 0.0165 |

| 11 | 0.51 | 131.412 | 5965.1 | 1.49 | 71.7 | 1.3 | 14.3 | 0.0192 |

| 12 | 0.47 | 144.088 | 6540.5 | 1.64 | 78.6 | 1.32 | 15.84 | 0.0212 |

| 13 | 0.45 | 149.482 | 6785.3 | 1.70 | 81.5 | 1.35 | 17.55 | 0.0235 |

Locomotive with B and U units and three Lionel Madison-series heavyweight passenger cars

| TRACK VOLTAGE | Elapsed Time MIN | Speed FPM | Motor RPM | Speed MPH | Scale MPH | Amp Readings | Power Watts | HP |

| 11 | 2.58 | 26.048 | 1182.4 | 0.30 | 14.2 | 3.7 | 40.7 | 0.0546 |

| 12 | 1.24 | 54.419 | 2470.2 | 0.62 | 29.7 | 3.8 | 45.6 | 0.0612 |

| 13 | 0.80 | 84.302 | 3826.7 | 0.96 | 46.0 | 3.9 | 50.7 | 0.0680 |

Note that at 12 VAC, the locomotive alone was running at 78.6 MPH (scale), drawing 1.32 amps, 15.84 watts. When I attached the consist to the locomotive and ran it at 12 VAC, it slowed down to 29.7 MPH (scale) drawing 3.8 amps and 45.6 watts. I also bench tested the locomotive at 12 VAC, and it was drawing 0.8 amps and 9.6 watts. So, I prepared a pie chart showing the power profile at 12 VAC. As you can see, the majority of the power (65%) was consumed by pulling the cars. Overcoming mechanical/electrical inefficiencies consumed 21% of the power, and the remaining 14% was consumed moving the weight of the locomotive.

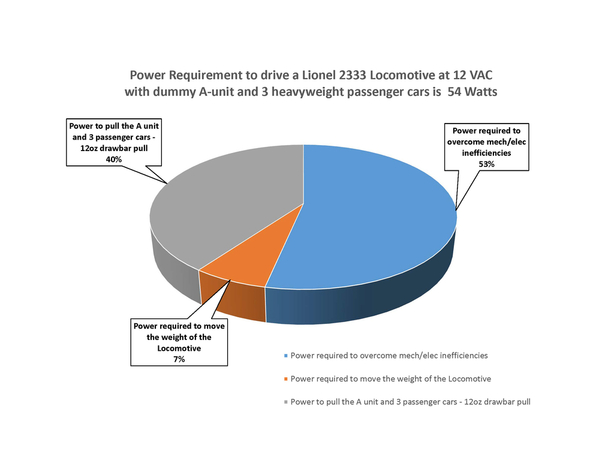

You are probably wondering, how this compares to the other locomotive I mentioned above – the post-war Lionel 2333 New York Central F3. I prepared another pie chart showing the power consumption profile for this locomotive under the same operating conditions, i.e. on the bench, on the track (locomotive only), and on the track pulling the dummy unit and the 3 passenger cars.

The one thing that I noticed right away was the difference in motor efficiency between the series-wound universal motor, and the permanent magnet DC motor. The latter being much more efficient than the former. As you can see from the pie-chart for the Lionel 2333 locomotive, 53% of the power was consumed by electrical/mechanical inefficiencies compared to just 21% for the MTH Santa Fe F3. Also, worth noting is the power that the MTH Santa Fe F3 consumed by pulling the dummy units and the passenger cars. At 12V, the MTH Santa Fe F3 consumed a total of 45.6 watts, with 29.76 watts just to pull the mashup at speed. On the other hand, the Lionel 2333 New York Central F3 required 54 watts total, with 21.6 watts just to pull the mashup. The mashup pull wattages aren’t’ equal because the MTH F3 was running faster at 12V than the Lionel F3 – and as we all know, it takes more power to go faster.

Overall, I am very impressed with the performance of this 1998-vintage MTH model 30-2131-1 Santa Fe F3. It is a superb locomotive, but I am not sure how durable the electronic components will be. It is remarkable that my 1949-vintage Lionel 2333 New York Central F3 is 74 years old and still runs reliably – probably as good as new. I wonder if this MTH Santa Fe F3 will be able to stand the test of time.

Here is a video clip of the Santa Fe F3 pulling the passenger cars.

Here is a video clip of the Lionel 2333 New York Central F3 pulling the passenger cars.