Hello, I recently bought a basket case 226E. I've completed the tear down and have ordered parts to get it running again. My question is about the coupler on the tender. It's missing except for the coil which still works. Nobody seems to sell a reproduction coupler assembly. There's a complete 6 wheel truck with coupler and pickup on eBay right now but I'm certain it will go for as much or more than what I paid for the whole thing. Could I buy a 4 wheel truck and take the assembly from that and use it? I don't necessarily need the coupler to operate automatically.

Replies sorted oldest to newest

Look here:

http://pictures.olsenstoy.com/cd/b123/000327.pdf

Looks like you could use the some or all of the following:

CP-38

2226T-15

TS-5BCH

Can't hurt to reach out to @Harry Henning as he deals with quite a bit of prewar parts in addition to @sharon.ottparts (Olsen's Toy Train Parts)

Maybe I can help you with that. I recently refurbished a 226E and that same tender. I bought a tender frame with trucks to get the correct coupler setup and I've got several leftover parts that may be what you need. Tomorrow I'll get it out and take some photos.

I looked on eBay and didn't see the truck you mentioned. I see a truck with a knuckle coupler, but that's postwar and not what you need. I see a complete frame with whistle that you could use but it's already up to $56 + $11 shipping. Did I miss something ?

Back on this tomorrow.

Malcolm Laughlin

Jeff Kane, the Train Tender sells several reproduction box coupler kits. Look at his web site where he has photos of various coupler parts with part number identification. That coupler with the tapered pin was used the bent lift plate. I think it is one of the more unusual types. Also look in the prewar Greenberg guide. There is a whole section on trying to explain the different box couplers. I think when Lionel introduced the box coupler they changed its design every year trying to get it right. Then the war came along and that was the end of it.

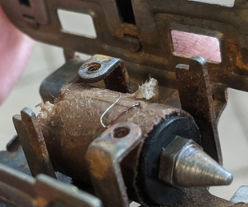

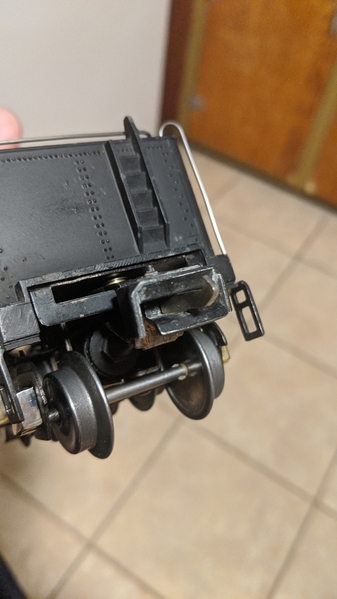

Hi guys, Ive been going back and forth with Jeff Kane but he doesnt have the coupler assembly I need. I believe its called HBC or high box coupler. I've attached a photo of the one on ebay. Its a complete 6 wheel truck. Also a rear shot of another coupler on a tender. Right now I have a 6 wheel truck with just the coil with a crayon style tip. The coil does bench test good.

I want to keep it original prewar even though most of my stuff is PW.

Thanks all.

Attachments

Did you reach out to @Harry Henning of Henning's trains as you were pointed to before? He could be considered King of prewar parts.

Wow...she is a basket case....I would welcome the challenge...good luck...post pics of the finished product....joe

The non-operating box coupler on that list is close to what you want, but the shank is too short. A key problem is that the coupler mounting is designed with a connection to the truck so that the coupler swivels as the truck turns to align the coupler with the next car.

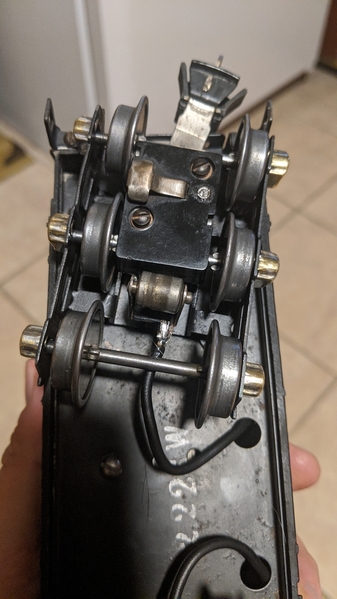

Could you post a photo of the underside of the tender. I'm going to go down and take a look at my postwar Berkshire tender and see if it has the same swivel mechanism and post a photo if it does. I've also got some leftover parts from a 265T with six wheel trucks that I bought to get some parts for my 2226T, so I'll look for that also. The swivel mechanism is the kind of Lionel design that I'd never have understood without looking at one.

If you're not worried about radius for coupling to long cars, you could just do an independent mount of an ordinary box coupler. Henning's OT-11 looks right bu the shank is too short.

Malcolm Laughlin

I've got the exact coupler that you need as you said manual operation will do for you. I'm busy in a meeting for a couple of hours but will send photos this evening showing the coupler and how the mechanism works.

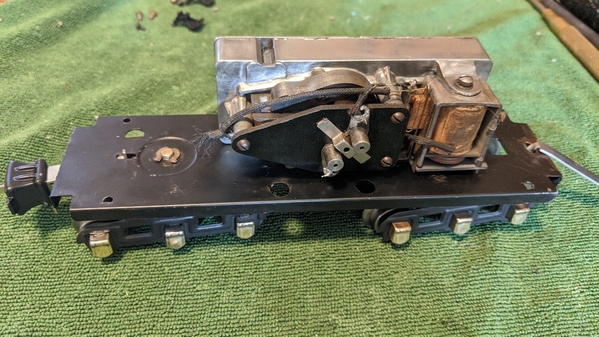

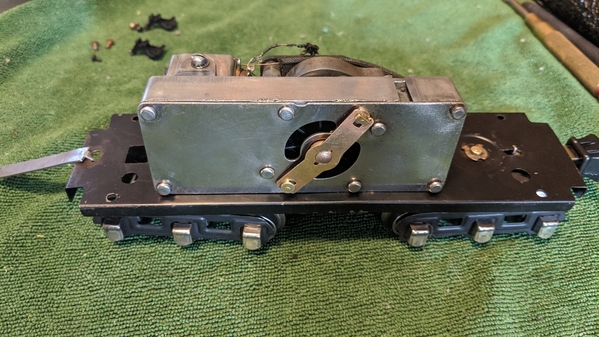

Here are some photos of the 2226 coupler showing how it works. It wouldn't be very difficult to make it work automatically, so I added some ideas on that. This is all the result of a rebuild that I did on a 226 several months ago. It was missing some tender truck and coupler pieces. I had the good fortune to find a 2263W tender frame with trucks. It's the same trucks as the 2226W. Now I have some leftover parts that I'm thinking about listing on eBay. Among them is the coupler that J needs.

Here is the coupler, and next to it is the truck and frame.

In the photo of the truck that needs a coupler, you can see how the coupler is broken off just beyond the mounting hole. I see that the snap ring and mounting post are there so they can be reused. In the next photo, the pencil points to the tab that goes into the slot just above the pencil point. The third photo shows how they fit together. I used a flathead screw as pivot just to illustrate how this works.

It's a clever mechanism. The tab and hole spacing is just right so that turning the truck causes the coupler to pivot so that it is exactly over the center line of the track on a curve. Here it is with the opposite turn.

For automatic operation, you would need a pickup shoe and a different plate on the back of the coupler. Placing a pickup shoe over that conical electromagnet would be simple. The next photo shows the part on another frame that I happened to have. The third photo shows how the underside attaches to the coil with a short length of wire.

The conical mechanism is what Lionel used in 1938-39. The plate projects upward at an angle over the magnet. In 1940-41, Lionel used a vertical plate that was pushed by a solenoid, and that is the coupler that I have. I see two fix possibilities.

1. Bend the vertical plate about 110-120 degrees, and add to it a small piece of magnetic material that will project over the cone - not sure if it's feasible to bend the plate that far.

2. Saw off the lower part of the plate, fashion an extension from kind of magnetic material and attach it to the upper part of the plate on the back of the coupler box. Since steel isn't easy to solder, I'd use epoxy for the plate.

Hope folks find this useful.

The coupler and other parts of the 2263 including bare trucks are for sale. If anyone is interested, please contact me directly by email. I see that Hennings is charging $7.50 for the regular box coupler with standard shank. As this particular coupler is hard to find, I'd say $15 would be a fair price.

Attachments

Thanks for the info. Definitely would be interested in the coupler. Will post more later tonight or in the AM.

This is great info; just another slant from what I learned the hard way; the pencil point/crayon point solenoid coupler release, uses much thicker axles and the journals are designed for thicker axles; the bottom plate is mounted with 2 screws as your excellent pics show; I believe they were used in 38/39. I believe in '40 Lionel went with a much narrower cylindrical bar for the coupler release and mounted on a base plate attached to two much thinner axles with 4 fingers around the axles; the journals have a carrier for the smaller diameter axles. Why do i know this? Because I tried to mix and match and it was not pretty. So bottom line, I should have gone with a "crayon" solenoid as original. Please correct me if I have bad info. But great info above; thanks much; Falcon70

Interesting comments Falcon. You are right about 1938-39. According to Greenburg on prewar O, Lionel went to the solenoid instead of the cone in 1940.

I'm puzzled about the axle comments. I looked at my 2263W trucks and the axles looked smaller than those on the conical coupler trucks. But when I checked them with my calipers that can measure .001", I found they were both 3/32 - seems like an optical illusion problem. I then checked several other cars with both early and late coupler types and didn't find one that didn't measure 3/32. I got the same result with postwar cars and tenders.

Those four fingers around the axles seem to me to have enough play to accommodate at least a 1/32 difference. I had been thinking about using one of them when I was working on my 2226 tender, but there is a problem with axle spacing. The tender axle spacing is 28mm, and four wheel trucks are spaced at 26mm, just enough to not fit the tabs. I had figured out how a four wheel truck mechanism could be adapted but wasn't looking forward to such meticulous fiddling. I got lucky and right at that time the 2263W frame was on eBay for $49. Seems like a lot for a tender frame, but I ended up with an easily salable tender rather than one with a jury rigged coupler.

So it looks like my tender since it has the magnetic cone is a 38-39 version. I'm thinking if I get your part AND something like what is in picture 1 I will end up with an asembly like this 2226 that I found on ebay in picture 2. Looks like I can pull the shoe collector and roller lever?

Attachments

On the axle thickness, I never noticed on the earlier (38-39) 2226WX tenders with the pencil plunger; since the bottom plate was trashed, I tried to replace it with rivet shoe version (rod plunger) version of 1940 and it was a surprise trying to mount it; the fingers did not wrap around the axle as well as the 1940 version. I had no idea; one can find pictures of the two versions on the bay. To your tender, it should work. I have read that Lionel went with the rivet shoe in 1940 as the 38/39 version contact arm got activated on switches. Also the rod plunger worked better on release. I just keep learning. That 2226W sure is a nice tender; Falcon70

Do you have the roller ? Do you care about being able to use the whistle ?

I have a truck in my junk box that has the pickup with a roller attached. It's also got a bent plate that I could switch for the vertical plate on the coupler. I'll have to check axle measurements to be sure that extra 2mm spacing won't be a problem.

I'll do some measurements and drawings and send you the drawing. I'm getting a bit fuzzy-minded now so will do that tomorrow morning.

Looks to me like we can certainly get that tender truck fixed. Solving mechanical problems like this is good mental recreation for me.

Going through my prewar junk box, I've found parts enough to finish the job on your coupler and tender truck. I never throw away a Lionel part and over several years have accumulated many truck and coupler parts. Several parts to this discussion, photo of parts here.

- Plate on the coupler box. In the second photo, you can see how the plate is bent to project above the magnetic cone. It's the red part marked "B" below.

We'll also have to take care of the coupler pickup shoe and the contact roller for the whistle.

This has been quite a challenge to my drawing and iPad photo abilities. I'll begin with a drawing that shows the essentials of the uncoupling mechanisms and the difference for the two periods. The second drawing shows the roller pickup end of the mechanism.

Here's how the coupler fits the drawing. I have figured out how to remove that coupler box plate and attach it to the tender coupler.

On the lower left in red is the plastic plate for the pickup shoe. The L shaped extension holds the pickup roller for the whistle. The next photo shows how the roller pickup doesn't quite match the pickup shoe plate. That can be fixed with a bit of cutting and a splice plate that I could easily cut from that piece of 1/64 tinplate.

Also note there is a wire on teh top side of the pickup shoe that has to be soldered to the coil wire.

Putting all of this together, now it doesn't seem like a difficult job to get that tender truck and coupler full functional.

Attachments

Looks great! I appreciate your R&D on this. How much do you want for everything?

In regard to how much, best we confer privately and decide how much of the project you want me to do and what you might do yourself. I will ,however, for the interest of other forum members who been reading this, summarize what needs to be done. I’m assuming there is a working whistle for which the contact roller is needed. From your photo of the tender, it looks like the whistle needs some work, but fortunately Lionel used the same whistle for about 20 years so it's easy to find low cost replacements.

Given the 2226T truck with coil and conical magnet in the original photo plus my 4 wheel truck frame and pickup roller.

- Remove the bent box plate from the 4 wheel frame, and use that to replace the straight plate on the on the tender coupler. Then it will be ready to work with the cone magnet.

- Remove the broken shank of the old coupler, saving the rivet and snap ring. Set the coupler, rivet and ring aside for the final assembly step.

- Unscrew the pickup plate from the 4 whl frame and clip the wire to the coil. Looking at Namdray’s photo, I believe I see the lead on top of his coil.

- Attach the whistle pickup roller to the pickup plate. For this step, the wheels must be in the tender truck frame to allow checking the height of the roller before joining those two parts.

- Solder a connection between the coil and pickup plate, and screw the plate with roller on the tender truck.

- Put the shank of the coupler through the slot on the tender end, placing the tab in the slot with the rivet through the hole from the frame side. Then attach the truck to the tender frame, placing the hole over the rivet. Finally use the snap ring to hold truck and coupler together, and put the clip on the truck kingpin. This is one of those tricky procedures that makes one wish for a third hand, but I did get it done on my own 2226T after several tries.

Thanks for the info and glad we met. I figured I would give an update for anyone that is interested. I bought the engine and tender online knowing that it did not run. The coal pile on the tender was broken and the engine was missing it's rollers from collector.

When I received the engine I realized that the collector was too mangled to save.

Thee-unit fired but the drum shredded itself into pieces. For these reasons I decided to buy a whole new motor assembly.

Attachments

New parts added besides the replacement motor were a new coal pile and front steps for the tender, a couple of handrail stanchions for the engine, new eccentric cranks and crossheads. I used a repair kit for the boiler marker lights. I'm not 100 percent happy with my job on them but it'll do for now. The valve gear and rods are original, just derusted with vinegar and polished with metal polish.

The whistle works. I put a repo MTH coupler on it until I get the correct parts to get the automatic coupler fixed. I've derusted the tender trucks and need to decided how to finish them. I've seen them all black and some black with nickel or brass journals. Not sure if Lionel painted the trucks or if the metal was finished another way. Ive had good luck by blackening metal with oil and a torch so I was thinking about trying that.

Attachments

Nice job on the whistle, sounds great. What kind of transformer are you using ? I noticed that it slowed slightly while the whistle was sounding. Has anyone solved that problem without resorting to electronic circuits ?

ML

Excellent job. Very nice.

ML I'm using an all original KW transformer. I've read some posts on fixing that issue but I don't recall the specifics.

The automatic coupler works great. For the roller because the tab was a little thinner I just tweaked the spring and it makes good contact with the third rail. I replace the wiring it's a little thicker than I'd like but until my order for thinner stick comes in it will do. It's almost time to start looking for my next basket case project. Thanks for everyone's help.

Thanks for sharing that with us and glad I could contribute. Just today I found someone who wanted my plain six wheel trucks, so all that I have left to dispose of now is the 2263W frame stamping.

There you go! Thanks again.