Thinking about doing it anyway. Am I correct in assuming ERR's AC Commander is the proper board for this conversion? Are the F3 horizontal dual motors' amperage draw too high for this board? Am I crazy to take a good running beautiful postwar locomotive like this and alter the way it was meant to be? Your thoughts and comments are appreciated. RICH

Replies sorted oldest to newest

Altering the locomotive? That's a personal decision, as a model railroader it would be easy for me to decide; i'd do it. If i were one who plays with toy trains, collects them with the idea they're investments, etc., the answer would probably be no as they're original only once.

AC Commander yes; Amperage draw from 2 Pullmor motors? i've never done one of these for a customer; call Ken at ERR for an accurate answer.

jackson

P.S.

See you have an interest in motorcycles. i tore up my leg putting down a Norton once. The last bike i had was an Ariel Square Four. Always wanted a Vincent or Brough Superior, but way out of my price range.

Rich, modeltrainparts is correct about contacting Ken. I have communicated with him often, he is a real fine fella. As for the AC Commander, I have installed in Lionel Postwar F3s with no problem, and great performance. As for the more modern engines, have also installed the DC Commander in many MTH PS1 engines as an upgrade, glad I did every time. My next endeavor is repairs to cherry switch and U-joints in my Niagara form Lionel CCII. But, I have no problem agreeing to use ERR components as any upgrade you intend to perform.

Jesse

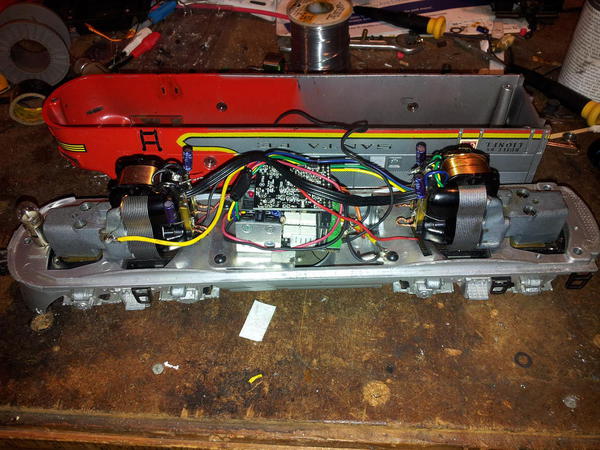

I installed an AC Commander in an MPC era dual pullmor motor F3 with no issues. It was an easy install and runs great. While original 2353's are not rare, if it is especially good then you might reconsider or at least retain all of the original e-unit and stuff that way should you want to part with it the potential future buyer can decide what they want.

My 2343 has TMCC installed. It has been operating for several years with TMCC. The 2343 was operator quality with a few scratches when I obtained them. I still have the old e-unit and horn equipment to convert back if I ever wanted to. Also, I rebuilt the motors and replaced the bronze bushings with ball bearings which greatly reduce the amps that the unit draw and eliminates the "coffee grinder" sound effects.

Attachments

Thank you all for sharing your thoughts. It may come down to deciding if the condition of the engine is worth it. I posted about this particular 2353 some time back. It's a solid C7+ with the original boxes, and it runs great, but I'm not thinking of selling it, so perhaps this isn't the time yet. On a positive note the horn is in the dummy A which would make things easier. Hey Jackson, we keep riding no matter what, right? I average an accident every 20 years so I'm good for another 15 when I'll be 80. RICH

My 2343 has TMCC installed. It has been operating for several years with TMCC. The 2343 was operator quality with a few scratches when I obtained them. I still have the old e-unit and horn equipment to convert back if I ever wanted to. Also, I rebuilt the motors and replaced the bronze bushings with ball bearings which greatly reduce the amps that the unit draw and eliminates the "coffee grinder" sound effects.

WBC, thanks for the photo. If your email is in your profile, I'll be in touch. If it isn't, shoot me an email. I'm very interested in a similar conversion, and I'm curious about the ball bearing replacement process.

Thanks, again, for the photo and information.

There is some art in putting in the ball bearings because Lionel uses a curious mix of metric and imperial sizes; even from the postwar era. I do find the measurements of the postwar era much more consistent than those since 1970. The shaft size of my 2343 motors is 0.1865 inch, which a 3/16 inch or 0.1875 i.d. ball bearing works. The end of the shaft (where the gear is) I used a 0.1875 inch i.d. x 0.3125 inch o.d. x 0.1250 inch width. This bearing fit snugly into the motor housing bore. Ball bearings of this size are available from Boca Bearings.

Replacement of the large bearing next to the armature takes a bit of art. I have accomplished this in various motors using a couple of different methods depending upon the shaft size of the motor. The cavity size is 0.4345 inch which an 11 mm bearing is a kissing fit. 11 mm is 0.4331 inches. However, 5 mm (0.1969 inch) is the closest metric size to the motor shaft size. I have found motor shaft sizes range from 0.1830 to 0.1870 inches. For narrower shaft sizes I use some ultra-thin heat shrink tubing to make up for the difference. I have also used a polymer system such as epoxy or methyl cyanoacrylate for making up the difference, but you have to be careful not to get the polymer liquid into the bearing itself or it ceases to function.

For the 2343’s the shaft size was too large to use the heat shrink tubing as the shaft + heat shrink tubing would not fit the 5 mm size. Thus I used 0.1875 inch i.d. x 0.3875 inch o.d. x 0.1250 inch width ball bearings from Boca Bearings. I had some Teflon tubing with an i.d. of 3/8. I inserted the tubing into large bushing bore in the motor housing and then pressed in the ball bearings. I pressed in two ball bearings. I then pressed on the gear and assembled the motor.

So the ball bearings sizes used are a 0.1875 inch i.d. x 0.3125 inch o.d. x 0.1250 inch for the gear end bore and either 11 mm od x 5 mm id x 4 mm w or 0.1875” id x 0.3875” od x 0.1250” w for the armature end bore.

Unfortunately I did not take any pictures of the 2343 motor. I did of my modern era Berkshire which I attached.

0.1875 in x 0.3125 in x 0.1250 in ball bearing in the worm end of the motor.

11 mm x 5 mm x 4 mm ball bearing at the armature end of the motor.

Attachments

I have installed a couple of AC commanders in dual-motored locomotives, never an issue. I currently still own one of them, the Phantom I locomotive that I added a second motor to and used the AC Commander in the upgrade.

Thanks for the input gunrunnerjohn. Do you think horizontal motors would draw higher amperage than vertical motors maybe enough to make a difference?

The AC Commander is robust enough to handle them, you can ask ERR, but I think the answer will be the same. The board is rated for 8 amp output, if your engine is drawing half of that, something is probably broken. My Phantom pulling five cars (set plus one) draws less than 2 amps.

Good info. Thanks again grj. RICH