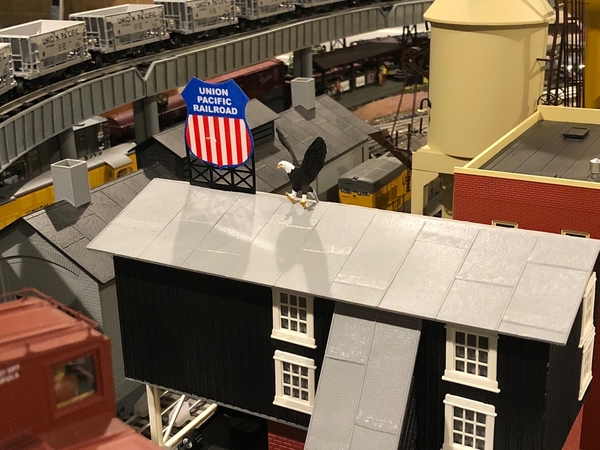

Several weeks ago, my "Great Room" looked like this:

Then I had the notion that it was time to take down what I think of as a big (12' X 17') layout, plan a smaller one and return our Great Room to it's intended purpose, so first it became this:

Since this is the third time downsizing using Mianne Benchwork, I found that I had many extra legs and I-beams, so my wife suggested that I create a 10' long section using the benchwork and, adding (Glenn Snyder) shelving. This will serve three purposes: display my trains that will no longer fit on my smaller table, create a space for storage of my train boxes (since each of the three sections can be slid out), and become a table top for our new 65" TV that is due to arrive soon!

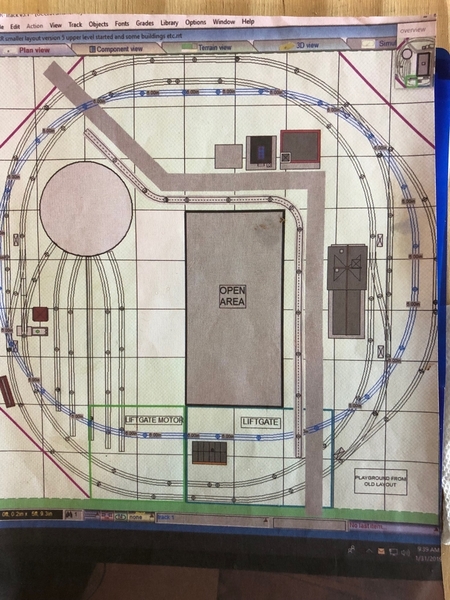

The new 9' X 9' train table is quickly being assembled on the opposite side of the room. I was able to re-configure the benchwork to include my liftgate (Tim Foley provided the i-beams needed to shorten it by one foot), my Bowser 24" turntable and another section of the big layout that included a school and playground:

I'm still working on the layout plan, but I think I will be able to create some nice scenes and likely run three trains at the same time, have a trolley line and five tracks to park engines around the turntable.

Change is real!