Still having issues with this thing.

1. Reed valve on top of piston is in great shape.

2. Substituted some 1/8" Tiki Torch fiberglass wicking for the little wick pad it came with because that wick pad is not available.

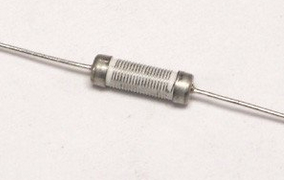

3. Was smoking a little bit at medium to high speeds now it doesn't. Resistor tests out at 21 Ω so I assume it is OK.

4. Opened it again and the smoke fluid had flooded everything. Fluid got down into the piston and beyond. That might be the problem, but it is difficult to prevent that (see below).

Questions:

1. I ordered a 14mm x 12mm x 1mm Silicone O-Ring to replace the nitrile O-Ring it came with to see if it pushes more air into the smoke unit chamber and thus more smoke out the stack.

2. Can I cut the sleeve off the resistor for better heat or would it just burn the wick more?

3. What I don't understand is how to keep the smoke fluid from going down the air vent into the piston cylinder since the hole leading to it is right under the smokestack where you put in the fluid. I guess the original little flat wick pad prevented that, but it also blocked puffed air from the piston from puffing the smoke out very well. CATCH 22 situation. Has anyone found a workaround?

Thanks,

John