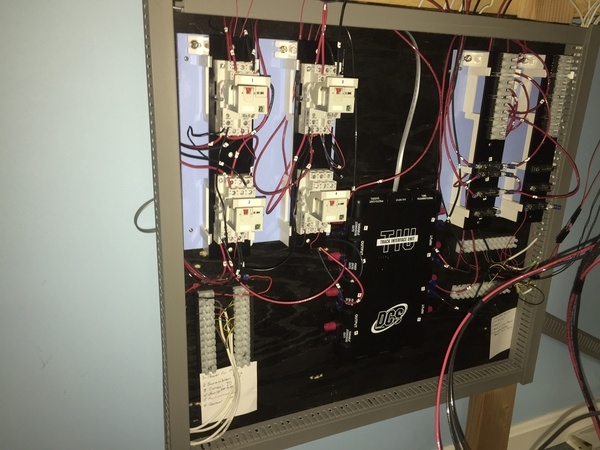

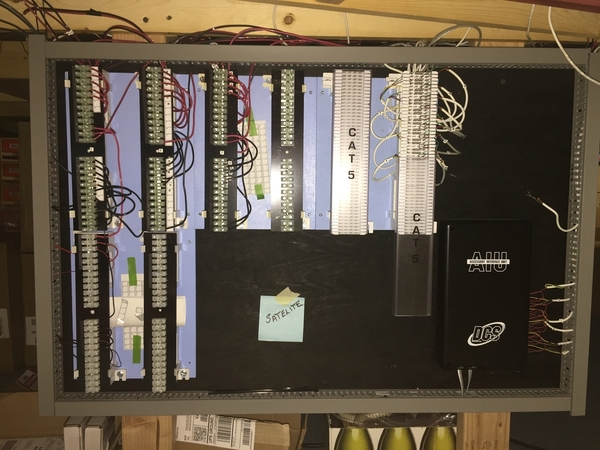

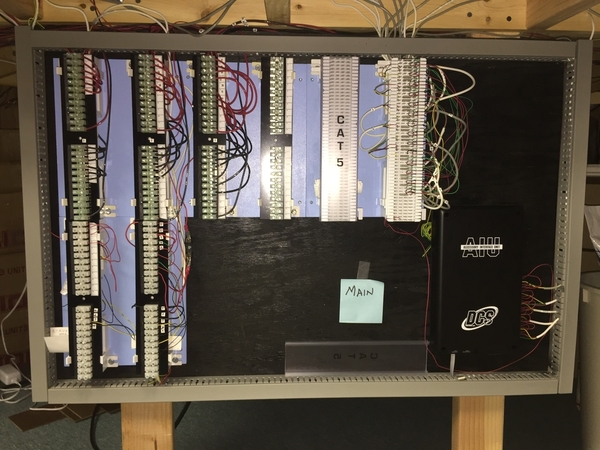

I'm a relative newbie to this with tables for a 10'x14' layout almost done. Once tables are done I think I can begin to lay track but I have a control question. Background is I have acquired, but have no experience with, DCS and Legacy systems ("L" TIU/remote/AIU, 990 system with Z4000 transformer).

So, how advanced of a switch panel should I develop as I'm just starting out? How did you all start... what do you have now? I have mostly post-war/early modern but a scant few PS2 and TMCC (I'm a newbie remember). Will buy more PS2/3/Legacy in the future but not looking for the newest and best, at least at this time (I got kids so will have to keep the good stuff under lock and key... an upper shelf doesn't work anymore as they now know how to climb!).

If I want to run the gamut of post-war to current MTH Premier/Legacy you still want a panel of some sort... right... right?

So I'd love to see what you all have and learn what your thinking was in progressing from conventional to the current state-of-the-art control systems. Responses should cater to us newbies who, while they may be technical proficient, are new to model train control.

Kirk R

![zar022[1] zar022[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/79142442892052360/filePointer/79283631251698250/fodoid/79283631251698246/imageType/MEDIUM/inlineImage/true/zar022%255B1%255D.jpg)

![zar022[1] zar022[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/79142442892052360/filePointer/79283631251698250/fodoid/79283631251698246/imageType/SQUARE_THUMBNAIL/inlineImage/true/zar022%5B1%5D.jpg)