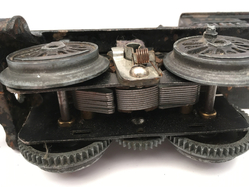

I second the Marx theory. It's the fat wheels (geàred)

I wrote, then noticed some big issues in the pics .,... but I'm gonna post it anyhow

But I doubt it is 100% dead just because of looks though(didn't, I think its hardly worth the bother now) One of mine was literally buried in the earth for 20years or more and was near frozen solid, but ran once cleaned (dunked and soaked in water, then I oiled it like mad, and it ran better and better with time, and still runs today.)

Dont pull the wheels, shine the armature plates, clean/check brushes and brush tubes, oil axles, wait a day, do it again (till they weep clean oil vs black streaks, clean more frequenty) (or solvent flush and reoil)

The wheels have a soft oxidation going, strip it from the working surfaces by dremel wheel, med-fine abrasive paper of choice, etc... spinning the wh3els for a lathe-like removal of material/oxidation if you can. Not spinning may produce a flat spot/ out of round. If the motor is clean, jump it by gator clips and run it while dressing the spinning wheels. Keep dust from falliing on the axle areas

The shine won't last. Tarnish happens pretty fast until you clean/dress them a few times, then it will slowly remain pretty longer. I do a final cleaning of dressing dust with solvent (thinner, spirits, alcohol, wd 40, electric spray..whatever, then for the last few years, wahl clipper oil on the tread and flange, then wipe the wheel as clean as I can with a clean rag. The clipper oil isn't real slick, it's more a sheeting oil, a very light penetrate. I just saw the brushplate is cracked. Robert Grossman Co for Marx parts, but checking what you have by meter on the armature and field would be a good idea first. If they read fine it should run.......

Except now it looks like the frame is bowed.

And has no shoe plate.

I'd likely look for another to replace it unless your doing a resto. If the replacement is the same, you could borrow its plate to test it; leaving you a possible extra for the next shell.

Could you file the flanges down or grind the cylinders more ? Deepen the mounting slot so the shell shifts forward more. offset of the body to one side is common too if the wheel sides hit the body. Or raise it. Thinning on The wheels face side could help (the gauge is likely narrow as is, I can see a lot of axle tip showing)