As requested, here is how I built my electrocouplers that match the profile of the existing couplers. I really enjoyed this build though there were some minor setbacks in the beginning. I’ll start by listing the hand tools and items used (see pics at bottom), with pics to help understand the process. Needed: Dremel or similar, aluminum oxide cutting wheel, aluminum oxide grinding wheel, J B Weld 2-part quick-set epoxy, mill file, file card (for cleaning file since everything is aluminum), alcohol (or solvent of choice), swabs, aluminum offset angle 1/2” x 3/4” x 1/16” thick, Lionel Trackmobile Electrocouplers, dial vernier caliper.

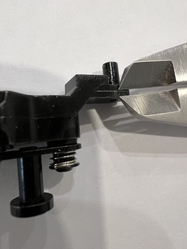

Step-1: Make a diagonal cut thru the Williams coupler, staying closer to the knuckle to ensure the usable section is whole. Set aside the attachment end of the Williams coupler until Step-3. Cut off the back end of the Lionel coupler. Use caution as to not nick or damage the coil wires. Remove as much material as you feel you can safely remove, use file to make surface flat and square to knuckle.

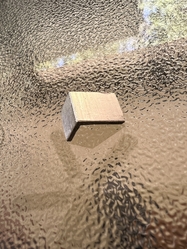

Step-2: Measure width of trimmed electrocoupler and cut a section off the aluminum offset angle matching this width. Try to keep cuts as parallel as possible to save trimming work later. Eyeball angle to ensure flat surfaces are at a 90Deg. angle, bend with vice grips to accomplish. Score surface of electrocoupler, and both flat surfaces of the offset angle, thoroughly clean the scored surfaces of both parts with alcohol. Set the electrocoupler on a flat hard surface and ensure the top of the knuckle is parallel with surface on both axis. Mix and apply epoxy to the electrocoupler and the 1/2" flat side of the offset angle, with bottom edge of offset angle on surface, press together. Provide a support to keep the offset angle in position, move on to Step-3 while epoxy cures for 24 hours.

Step-3: Using the file, square up the cut of end of the attachment end of the Williams coupler. Cut in a 1/32" chamfer to both corners. As cast, the attachment, not including post is .168" thick. I removed .048" from bottom of the attachment, this will cause the knuckle to sit only .014" lower than the st'd Williams coupler when installed. To provide a witness line for removing this material, set the calipers to .048", lock in place, set edge of caliper on bottom of attachment and drag across part on both sides. This will leave a witness line that will allow you to grind material off and keep the part relatively square. Use the file for finishing to the final thickness of .120", measuring around the part with the calipers to ensure it is square to the uncut surfaces. When satisfied, score bottom and thoroughly clean the attachment and electrocoupler assembly. Mix and apply epoxy to the attachment and the top of the electrocoupler assembly, position the attachment so it is centered with the knuckle body and the attachment shaft centerline is 1.2" from the centerline of the knuckle pin. Allow epoxy to cure 24 hours.

Step-4: Final process is to trim the offset angle so up to and around the attachment. Use care to hold the part securely if you decide to grind away, rather than file, the excess material. Undue vibration may break the epoxy bond. When satisfied, leave as is, paint, or touch up with sharpie as I did. This assembly allows you to use the stock centering springs though I'm presently looking for a stronger alternative.

Though I was trained as a toolmaker and later became an engineer many years ago, this project as laid out is well within the scope of anyone who is willing to take their time. I enjoyed the project and I think anyone attempting it will agree, once completed. Now on to two more sets!