@pennsy484: Thanks for that idea! I will definitely have to try that.

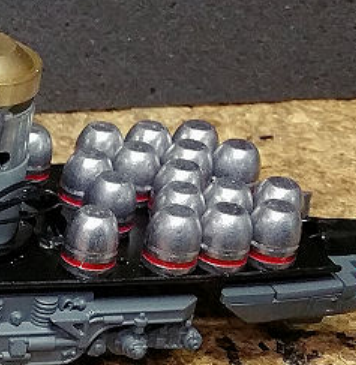

@RickM46: I didn't have much free time last night to investigate the head light further. I'm thinking perhaps that damaged wire is actually broken and that's the source of my headlight problem.

.

.