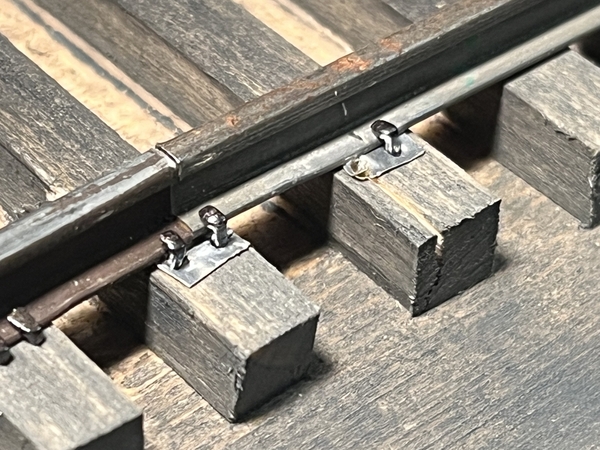

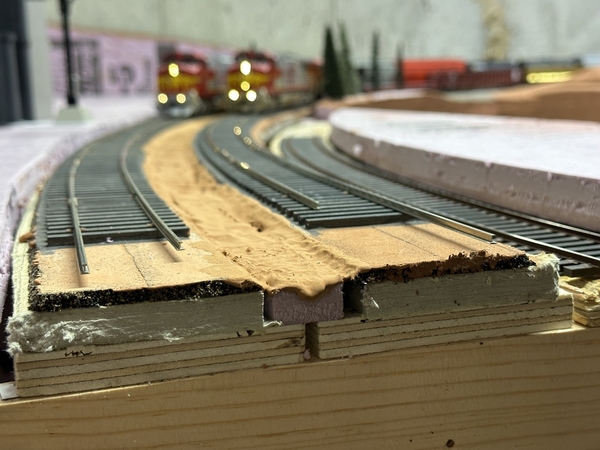

Starting a new project, adding an upper level with some two rail loops. I have my plan for the process, but how many glue ties to the plywood sub roadbed directly? I did a trial run so now working on the real loops. Messed around with making tie plates from an aluminum can.

Replies sorted oldest to newest

IMO, wood ties attached directly to fully second level plywood will provide plenty of vibration noise. Homasote will offer some noise reduction; just be sure your tie spikes (and any other "securing" implements don't reach the plywood.

Chuck

I'd be making roadbed with beveled sides from Homasote placing that on top of the plywood (glued and screwed; back out the screw later) to glue the ties on, and then spike the rail into the ties. If everything is a solid unit, minimizing potential for vibration, then it's quiet.

Wow, a lot of work ahead. My whole layout is 1/2” Homasote sheeting on 1/2” plywood with Fastrack screwed into the Homasote using shallow screws that don’t reach the plywood.

Still a little noisy, because it’s Fastrack, but has been trouble-free going on 12 years now. IMO, you can’t go wrong using Homasote. 👍

First of all you can buy tie and fish plates and unless you are trying to model a 1950's toy train layout used cork glued to the sub roadbed. can I ask what code rail you are using , and how big are your cross ties

@Dave Koehler posted:First of all you can buy tie and fish plates and unless you are trying to model a 1950's toy train layout used cork glued to the sub roadbed. can I ask what code rail you are using , and how big are your cross ties

Not going for proto 48, more of a 1940’s layout. Crossties are 1/4” square, yes I realize that is technically oversize for a 8 or 9” square tie. Your really not going to like the rail I am choosing to use for this either. Stripping the ties from American Flyer S track and using that rail. It’s probably close to code 148 though I have not measured it. I’m using 1/4” & 5/16” spikes. I did consider purchasing tie plates, but figured they would not fit the base of the rail I am using. Was thinking about making a jig to punch four uniform holes in tin can aluminum blanks. But very likely I will be too lazy for that.

Ditto on the Homasote over 1/2" ply and the track screws do not reach the ply. The Atlas track is very quiet... you should have very similar acoustical results with hand laid track.

No. I get it, , the profile of the Flyer rail , should be close to the Lionel T rail but with wood ties. I can see your collection of vintage car s built from period kits running on it now. Are you going to install an outside 3rd rail?

Yes, I do plan on outside third rail. Not sure if it will be on both loops or just one. While I do have some doorstop stuff insulated for 2 rail, most of what I have collected over time is not. We'll see, it's a work in progress.....

I could have just thrown down some Gargraves, I probably have enough, nothing wrong with that, but I eventually came to the conclusion I did not want to do it with Gargraves. This started with a four foot experiment which is the track with the old kit cars on it. It was easy enough with no special tools.... anyway, you know how it goes lol. The other part to not lose sight of at least for me, is I am adding these two hand laid loops as an upper level on basically a mid sized tinplate layout, so lots of compromise there, but I like both and collect both so it is what it is.

well it looks great, and your concept is sound. have fun and keep us posted

@Dennis Holler posted:Not going for proto 48, more of a 1940’s layout. ...

Carey Williams has done a lot of that kind of thing - I suggest looking at his posts or YouTube channel, or perhaps asking him directly.

@Mallard4468 posted:Carey Williams has done a lot of that kind of thing - I suggest looking at his posts or YouTube channel, or perhaps asking him directly.

Yes, Carey is a great resource! While I haven’t made it up to visit yet, we talk a bit on some other groups. But yes I definitely reference his posts, and quite a few others honestly.

The part 2 vid. looks great. I see what the oldtimers liked about steel rail over Nickel silver and brass , even though it Flyer rail, you cant beat the patina of weathered steel I think one of the 2 rail companies still makes it PS what was the electric loco with the body off to the right of the track

Nothing like building it like the railroads did in the 1800's! ![]() The track looks great, but boy is that a lot of work!

The track looks great, but boy is that a lot of work!

Looking good Dennis!

I hand lay most of my track and have experimented with different roadbed options including gluing ties directly to plywood. That works fine but the only minor issue I experienced was sometimes it was difficult completely pressing spikes in without bending them. There's definitely no issue with that using homosote roadbed though. Over the years I've settled on using O scale cork glued to 1/2" homosote glued to 1/2" plywood as my default roadbed configuration.

John

Attachments

It all Depends on what you want to represent. A less maintained or less traveled branchline or shortline would probably not have much raised roadbed. So laying ties directly on the plywood would represent this type of track. If you are modeling a high traffic class one mainline especially in the 1940s the track would be well maintained and well drained requiring very visible roadbed. So modeling that kind of track would work best using the homosote roadbed.

My experience is that once you ballast the track - ie lay ballast and glue it in place, the sound deadening affects of using homosote are pretty much negated When the glue dries it forms a hard material contact between the plywood and the track.

@prrjim posted:My experience is that once you ballast the track - ie lay ballast and glue it in place, the sound deadening affects of using homosote are pretty much negated When the glue dries it forms a hard material contact between the plywood and the track.

Valid point!

I have always wondered why model train books, magazines and message boards haven't discussed this phenomena more. Ballasting (with stone), although adding realism, results in an enormous increase in track noise. It definitely negated all the work I did to use cork roadbed upon the Homasote. I imagine the noise level would even be higher for ballasted track laid directly on the plywood.

I stopped ballasting on track areas not readily visible by guests. I also experimented using rubber ballasting but found it too difficult to lay down.