[I had originally posted a reply in a relating thread a few minutes ago but decided to delete it and start this new one]

Hi. My Hiawatha just stopped running. It had been flawless until this morning. I took it off the shelf and placed on the track, powered it up. Lights go on, tender makes noise, but it will not react to any commands from my Cab-2. The tender sounds start up as soon as I disconnect it from the engine and move it away.

it will not run in conventional mode either.

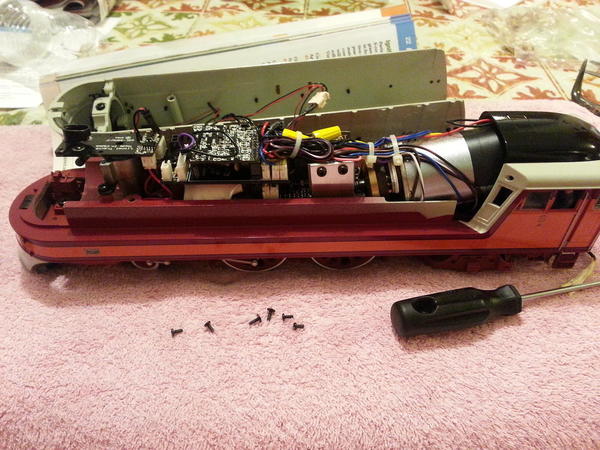

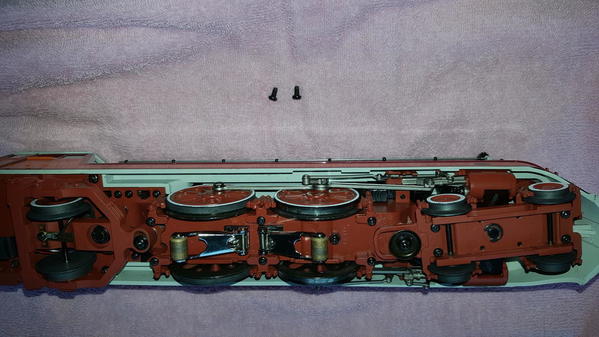

I"ve tried to open my Hiawatha up but the shell will not come off. I removed all the body screws to include that cover in the front. the shell comes up a bit all around but is "stuck"...I can't seem to find out why. Is there a secret to getting the shell off?

thanks,