Just read your comment on 24 vs 16. That solves my problem. Even 18 would be fine if it’s ok with timer/converter

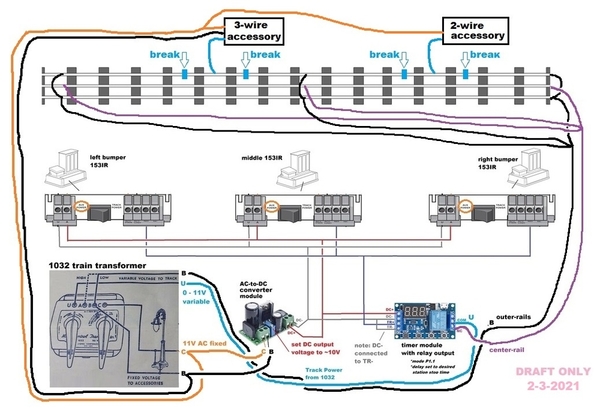

@stan2004 posted:To be clear, your 20 foot run is a single "block" of track. The center-rail and outer-rails are continuous from end-to-end. There are no cuts or breaks or "isolated" sections. The timer module has a relay which has ON-OFF control to the entire 20 foot track. All or nothing!

“No breaks or isolated sections” ?

I was planning on insulated sections to activate road crossing signals. Is that a problem?

Unrelated to that, can this “accessory” be used to turn station lights or parking lot lights (or a “Welcome to Twin Peaks”) Sign on and off ? A little more action to surprise the grandkids! This is complicated enough for me so if the answer is “yes but” then I probably am not interested.

No breaks or isolated sections are required for the timed station-stop function.

Yes, you can insert isolated trigger sections for the purpose of activating accessories. The diagram is getting a bit messy, but I attempt to show this above.

The basic crossing signal has 2-wires. One wire comes from the transformer Accessory AC (terminal C in the case of the 1032). The 2nd wire comes from the isolated section which supplies Accessory common (terminal B) when the trolley passes over the section.

There are more complex crossing signals with 3-wires (or even more). In the case of a 3-wire crossing signal the accessory always receives Accessory Power from 1032 terminals B and C. The 3rd wire is a trigger signal which activates and addition function (e.g., lowering the gate). The trigger signal is from the isolated section.

Of course the 2-wire accessory can be as "simple" as a light bulb such as to light a station platform only when the trolley is over the isolated trigger section.

Attachments

Stan,

Four areas of concern:

The timer module and AC/DC converter have finally arrived! Both look fragile. How should I connect them to the control panel. Should I create some kind of protective cover. ?

The timer module and AC/DC converter have finally arrived! Both look fragile. How should I connect them to the control panel. Should I create some kind of protective cover. ?

———-

To be absolutely clear, the wiring is to be run as follows:

1032 U to timer module

1032 B to Ac/DC CONVERTER module

independent of AC/DC converter module, B also attaches to outside rail and fixed voltage accessories

- should I run B to a terminal block and then run a line to the module and one or more to outside rails and accessories

From the timer module run line to center rail. the same wires go to power drops

Signal gates are connected to outer rail and both C & B from transformer

I understand the connections between the two modules and the 153irs

- DUH! I just realized their is no direct connection between the 153ir and the track itself (you told me, but a drawing is worth ....)

But, is the timer on the 153ir used? If so, One timer is set longer than the other?

——-

it looks like I’m going to be using 16 gauge stranded wire for the lines that go to the tracks I also have 18 gauge solid wire which I could use if the connection to the timer module is too small I also have 18/2 solid core wire which would make less of a mess under the table (see pic). Any recommendation?

———-

A friend who became aware of this project offered this unsolicited advice. He gave me the pictured AC Adapter (modified it seems) with instructions to attach the reds to the positive inputs on the boards and black to the negative. He suggested it would be easier. I don’t understand what the hook ups might be (yours I do, now). Its output is 12 volts (you said use 10). Would both plans work? Is there any reason to switch. Could I use the AC converter for any other purpose?

Attachments

While a good deal of this thread is over my head, the trolley stop is exactly what we want to do down the road with our short elevated trolley line using our MTH bump and go trolleys. In our case, it would be point to point but would only have to station stop on one end...we have room for the track/bumper to extend out about 12" past the station if I can figure out how to understand the stopping/timer part you guys have been discussing. Wish there was a simple add on type thing for our MTH Realtrax like the special Lionel track accessory...I'll be referring back to this thread for sure when we get ready to add this to our layout later in the year and see if I can figure it out.

@Don Baird posted:...

Four areas of concern:

(1) Both look fragile. How should I connect them to the control panel. Should I create some kind of protective cover. ?

Maybe in the end. But for now, whether it be with bailing wire and duct tape the goal should be to get the "automatic trolley" function up and running. I can't quite picture your layout but position the two modules where it makes sense relative to your track, transformer, etc. When the kinks are worked out then I'd probably suggest screwing down the two modules to a scrap piece of plywood or whatever using the mounting holes on each module (probably #4 screws should work).

(2) But, is the timer on the 153ir used? If so, One timer is set longer than the other?

Set all 153IR timers to the minimum delay which will be a few seconds.

(3) Any recommendation?

Whatever is easiest. Solid is "generally" easier to work with. 16 vs. 18 is irrelevant for this application. A trolley consumes very little current in the big scheme of things so you won't be pushing any wire-gauge limits!

(4) Would both plans work? Is there any reason to switch. Could I use the AC converter for any other purpose?

You could indeed substitute the 12V DC adapter for the AC-to-DC module. But you would have another AC-cord running to a wall-outlet or power strip. In my opinion there is something to be said for having ALL-THINGS-TROLLEY powered by your single transformer. Seems simpler. But to be blunt, and with no disrespect intended to your buddy, this is a distraction. I think you need to get the "automatic trolley" part of the system up and running. Otherwise there will be more diagrams that frankly just complicate matters. Downstream, once you get things running, you will likely want to adjust or modify the system. That would be a good time to re-visit your buddy's 12V DC adapter. In my opinion anyway...

You have bigger fish to fry.

Example of a bigger fish:

Take a look at your three 153IRs. Lionel changed the wiring instructions in their different versions. If you don't know the "vintage" (release date as printed on the first page of manual) of each unit to confirm compatibility, at minimum look at the 2 left terminals. Are they labeled U and A, A and U, something else, or no lettering at all?

@Canes RR posted:While a good deal of this thread is over my head,...

I am a novice at this hobby and when I started this trolley project had no idea what I was getting into. Everything in this chain would have been over my head. But with help from this forum I have learned much and gained much confidence. There are two things to note:

1. There are different ways to achieve your goal. These are discussed early in the chain. Stan worked with me to use all the pieces I already owned and do so inexpensively.

2. Availability and cost of parts The key element in my set up is the Lionel 153 IR which will operate many different operating accessories on many brands of trains. Google it for a full description. I began my project when I had only one 153ir. When I planned only two stops as you do, I knew I needed another which I found on eBay for under $50.00. When I decided to add a third stop I needed another. Both my local hobby shop and Amazon offered the product for less than $50.00 I’ve waited for months and finally turned to eBay once more. Since you are apparently starting from scratch, you can probably spend less. The AC/DC and timer modules were cheap ($4 each) but took 3 & 1/2 months to ship from China.

My message to you is meant to be encouraging. You can do it! There are plenty of folks on this forum who will offer whatever assistance you may need.

Skimming through some old posts I came across one from “Chris F” (“Lionel Transformer 1032 Hookup” December, 2005” which says that when UB is used as the variable power source no options for constant auxiliary power remain. No one in that chain challenged him.

Since I am planning on using UB for variable power and BC for constant auxiliary power this concerned me. Is Chris mistaken?

I think I found the post you mention:

"Terminal U could be used as the common terminal. You'd get 5-16V from Terminal A, and 0-11V from terminal B. However, there would be no fixed voltage terminals available with this connection scheme."

Note the first sentence of the paragraph. Your connection scheme uses Terminal B as the common terminal.

Lots of similar discussion and information here on the 1032/1033 and more on their wiring schemes:

https://ogrforum.ogaugerr.com/...out-1033-transformer

@bmoran4 posted:Generally speaking with classic transformers, in isolation, those designed to run a single train had the U terminal as the variable post. With transformers with multiple variable taps, the U terminal was the common ground.

Much of Lionel's documentation was focused on the simple layout, especially in their generic instruction sheets and it really didn't matter (inconsistencies can be found).

However, take a look at the advanced sections in this guide, specifically take a look at printed pg 43-45 (pdf pg 45-47) where it discusses common ground wiring. : https://ogrforum.ogaugerr.com/...sories%20%201954.pdf

The chart is expanded upon in the transformer section of the service documents.

Stan I’m finally wiring the trolley! I’m assuming I can use terminal blocks, for example, on your diagram, grey wires (2) from the timer are joined with one from AC/DC Converter and subsequently to the right and left 153IRs. It’s much neater if bring the 3 wires from the modules together at a single terminal strip block. Any reason not to do that?

Neatness is good. The grey wire is a good example. The 153IRs are up on the track. The modules are no doubt below the layout. So it makes perfect sense to connect the grey wires from the modules "locally" to a junction or common point. Then connect the grey wires of the 153IRs "locally". Then run a single wire between the two junctions.

Bigger Fish

re: the 153IR controllers

- in two of them the two left hand terminals are labeled A & U the four terminals on the right are labeled “AC power, AC ground, NO, & NC.”

- in third (1961 I believe) the two left hand terminals are labeled “power supply.” The four terminals on the right are labeled “Com 2, Com 1, NO, & NC”).

smaller fish. (Which hopefully I will have soon caught)

I am currently watching uTube videos about multimeters in order learn how to set the the voltage on the DCAC converter and check my track for continuity in my wiring.

reading this, it sounds less expensive, and less of a headache to get a mth brill or pcc and program it to go out and back

@Don Baird posted:...

re: the 153IR controllers

- in two of them the two left hand terminals are labeled A & U the four terminals on the right are labeled “AC power, AC ground, NO, & NC.”

- in third (1961 I believe) the two left hand terminals are labeled “power supply.” The four terminals on the right are labeled “Com 2, Com 1, NO, & NC”).

I was afraid of that. Unfortunately the mix of 153IR styles makes for a bit of legwork. Here's a "reference" diagram I've been working on with tidbits of info provided by other forum members when 153IR related issues arise. Hopefully we can confirm or add to the knowledge base. Not all of the diagram applies to your situation but my comments will be to the point.

Apparently you have two (2) of the upper right version identified as 2002 above...and one (1) of the upper left version identified as 2001.

What I need to confirm is these early versions can operate on DC voltage (as does the later version identified 2014). These need to operate on DC voltage as that's what is coming from the AC-to-DC converter module set to 10V DC.

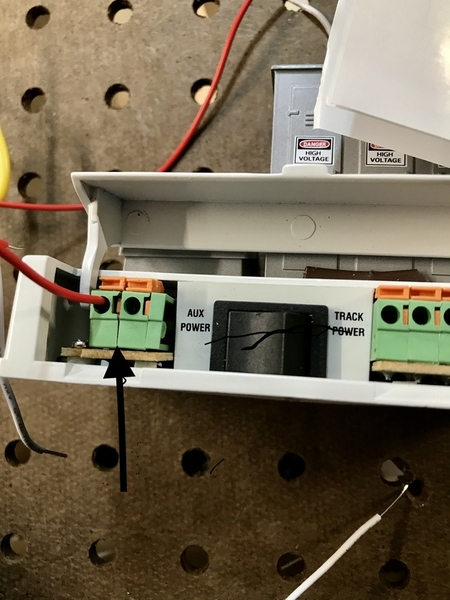

1. Set the Power Selection toggle switch to the AUX POWER position.

2. One 153IR at a time, apply 10V DC to the two power terminals on the left side of the 153IR. Get a pad of paper to take good notes. Apply +DC output for converter to the left (unmarked or A) power terminal and -DC from the converter to the right (unmarked or U) power terminal. There is NO power indicator, light or whatever on the 153IR to show power is "on". However, when you wave you hand in front of the 153IR you should hear the internal relay "click" on. When you remove your hand, after a few seconds you should hear the relay "click" off. You may never get any clicking action.

Whether you get the clicking relay or not, next swap the two 10V DC power wires. So now +DC goes to the right power terminal, and -DC to the left power terminal. Repeat the hand-waving to listen for the 153IR internal relay clicking on and off.

Report the results for the 6 experiments (2 experiments per 153IR).

@Don Baird posted:I am currently watching uTube videos about multimeters in order learn how to set the the voltage on the DCAC converter and check my track for continuity in my wiring.

Do you now feel comfortable using your multimeter to test for continuity? When you reach the point where you can touch the 2 meter probes to two different contact point and read the meter to determine continuity then here's more homework:

1. Confirm the 153IR Power Selection toggle switch is still in the AUX POWER position.

2. One 153IR at a time, test for continuity as follows:

Place one meter probe in the left power terminal (unmarked or "A" depending on version. if you have a needle or thin probe you ought to be able to insert it into the connector and 'clamp' it in place with the orange lever. Then take the other meter probe and one-by-one briefly touch each of the 4 terminals on the right side of the 153IR. So depending on the version, the 4 terminals are labeled left-to-right COM2, COM1, NO, NC...or... ACC PWR, ACC GND, NO, NC. Use the meter to determine if there's continuity for the 4 cases.

This will be enough information to tell me how to combine the 2 different styles of 153IR you have to work together as a team of 3.

Yes, I realize this seems quite tedious and time-consuming but I think all above can be done in maybe 30 minutes.

Attachments

@Don Baird posted:

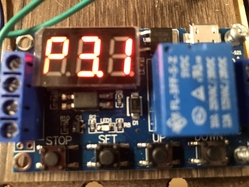

You want to get to mode P1.1. And you want to set the station stop time to however many seconds. Let's just call it 10 seconds now. I assume you're reading the mangled-English instructions on one of the eBay or Amazon listings for this timer?

Here's one procedure which I just tried.

1. Press SET for about ~4 seconds. Release SET. The display indicates Px.y.

2. Press UP and the display cycles thru P1.1, P1.2, etc. When it reaches P1.1, momentarily press SET. The display should blink OP and then blink some number XYZ. This is the station stop time in seconds assuming the decimal point is after the rightmost digit. As the time is flashing, use the UP and DOWN button to set the time to 010. If the decimal point is not on the rightmost digit press the STOP button to change the decimal point position. The STOP button will cycle thru XYZ. or XY.Z or X.Y.Z. Again, you want the XYZ. setting so that XYZ represents seconds. When you get the desired time (010.) press the SET button for ~2 seconds. The display flashes P1.1 and then reverts to a solid 000

It's now programmed. You can turn off power and back on and it remembers the setting. When you initially apply or re-apply power, the display should flash P1.1 for a couple seconds then revert to a solid 000 as it waits for a trigger to start its timing function.

The AC/DC Converter is set to 9.9

The AC/DC Converter is set to 9.9

I will refer too the 153 IRS as units

1. 2001with power supply on the left and terminals com2, com1, no, & MV on the right. This is the unit for which I have instructions

2 & 3 are the 2002 version

The “Clicking “Test” is

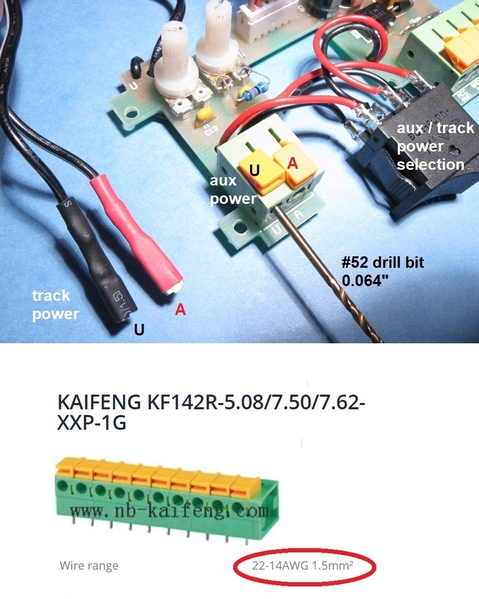

I am using 18 gauge solid core wire. Directions say nothing larger than 24! I ran into difficulty on unit two.

#1 A with + DC current connected to the unlabeled left hand terminal on unit one

- the unit clicked as expected

- reverse -DC Left terminal Nothing Happens

#3 the results are reversed The unit clicks when -DC is plugged into A

dors not click when +D is in terminal A

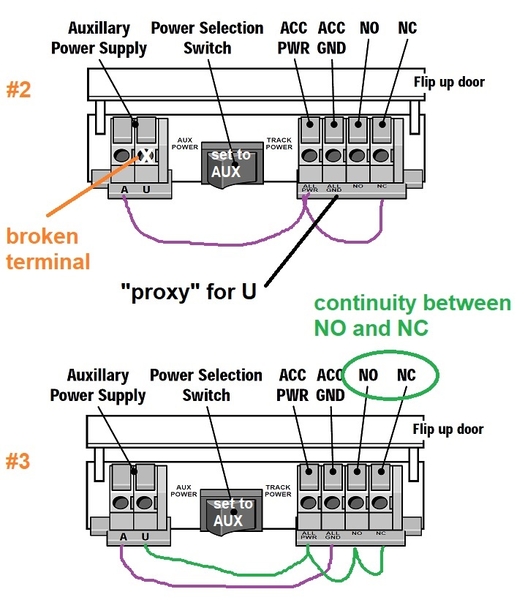

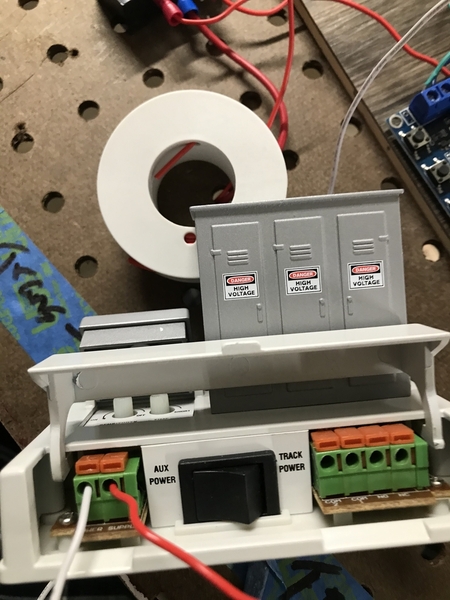

#2 unable to test Terminal unit u will not accept cable I noticed one difference between unit 2 and the others There is a small space (crack?) between terminals a & u on #2 see pictures

Continuity Test

Unit 1 2001

com 2 yes; com 1 no; NO no; NC yes

Unit 2. 2002

Same as #1 show continuity withACC Power and NC, but not with ACC ground or no

Unit 3

surprisingly shows continuity only with ACC ground. Decided to switch the leads placing -DC in A. With that scenario, each of the four terminal showed continuity excepting ACC power.

these results are mot helpful are they

I’m going to read the 2001 instructions again. They may have said that those units would lwork on AC or DC I’m not sure. If you haven’t looked at this I will edit and add the answer to that question

Attachments

I think we've entered the Twilight Zone! ![]()

Continuity and DC power test results understood on unit #1. Let's put that aside for now.

> Please confirm the two power terminals on units #2 and #3 are labeled A - U as shown in photos above (not U - A).

For unit #2 with the broken U terminal, I suppose it could be replaced/repaired...but to keep things moving, simply use the ACC GND terminal as a proxy for U. Based on your continuity test for #2, A = ACC PWR (connected internally)...this means U = ACC GND (connected internally).

> So you should be able to power #2 with DC+ to A, and DC- to ACC GND...and the unit should click. And if you reverse the power connections (DC+ to ACC GND, DC- to A), it should NOT work.

Assuming this is the case, we can then put unit #2 aside for now.

On to unit #3. You tested and found continuity between U, ACC PWR, NO and NC as depicted in Green above.

> This is a problem. Double check this. For example measure continuity between NO and NC. These should NOT connect together! Can you see any random loose strand of wire or whatever that might shorting the two terminals? Otherwise, the next step would be opening up the unit to find why NO and NC are tied together.

Attachments

@Don Baird posted:...

I am using 18 gauge solid core wire. Directions say nothing larger than 24! I ran into difficulty on unit two.

Separately, regarding the broken connector and wire size.

I only have a 153IR 2014 (U-A) version to play with and was experimenting with the largest drill bit I could comfortably insert. As shown it was a #52 which corresponds to AWG 14. The 2-terminal connector has an embossed part number KF142R and I found a datasheet which suggests a wire range of 22-14. So by larger than 24, I'm thinking Lionel meant no larger in # than 24.

In my previous post, I suggested using an unused terminal from the right block of 4 as a proxy for the broken terminal...they should be internally connected.

OTOH, if for whatever reason, the broken 2-terminal connector renders the unit useless by, say, shorting together A and U, another workaround would be to flip the Power Selection switch to Track Power and apply DC power to the Track Power wires as shown in above photo. This would take the broken 2-terminal connector completely out of the circuit. Again, the photo is a different 153IR version than what you have and is only meant to illustrate the workaround of using the track power wires to supply power - we'd have to double-check continuities of course.