I can't afford those $1K turntables so, other than making one (I can only imagine what that would look like), the 24" Atlas turntable is about my only recourse. Let's see yours so I can get some ideas!

Replies sorted oldest to newest

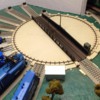

Bob....while my steam service area has changed quite a bit and I no longer use the Atlas turntable, here is what it looked like back a few years ago....

Alan

Attachments

Alan and Shep,

What other than price are the good and bad with the Atlas Turntables?

I installed the Atlas turntable it works great, easy hook up and runs fine. looks good on my layout.

My Atlas turntable does not see a lot of use. It has works fine when I do use it.

the only negatives I know of are it has no pit and the drive belt slips Sometimes. I have been told you can replace it with a o ring with good results. The positive points it allows people like me to have one on the layout. They also can be made to look real nice with proper scenery. I am not there yet. Jon

Dennis....I like the Atlas turntable but in my particular case, I needed to be able to have a turntable that would allow longer steam locomotives to travel on its bridge. So...at the time I was looking for a replacement, I met this "Al" guy and he convinced me to buy one of his turntables...![]()

The Atlas turntable has plenty of prototypical examples from which it was modeled. Yes, the pit may bother some because of how the bridge and pit are designed to turn together....but I have seen folks paint the pit area so the pit movement is not noticeable. Also...some modelers don't like how the bridge automatically stops at every track location rather than being able to index it to the track with which you want to align the bridge. Still, it is a nice turntable that is certainly a bargain in today's market.

Alan

Looks fine Alan.

Does it lay flat on the surface or is there anything that needs to be done below grade, like holes to be drilled or cut?

Does it come assembled, how much assembly is required?

Does it accept Ross/Gargraves track?

How many degrees between 2 tracks?

Did you use the manual operating feature or is it motorized?

My longest engines (Williams brass 2-8-2 and 4-6-2) are 23" long, they should be fine.

Best price I've seen is just above $200 for a new one. Haven't checked our forum yet or EBay. Would it be wise to get a used one?

Bob

It lies flat.

The only assembly is mounting the small girders (see Alan's 1st photo) at the center of the bridge. Most people don't bother.

Not without a LOT of work. Stick with what's there.

21 stalls, would have been 24 without the shed. I dunno how that works out in degrees - too long out of school.

I use the manual. I think the speed with the motor is too fast.

My largest engines that fit are F3's and the MTH Railking Challenger (26", but has a slight overhang).

Buy new.

I really like mine.

Alan,

That turntable looks great and I really love all the Pennsy Steam Engines. ![]()

Thanks guys ![]()

I'm looking at maybe building up the "ground" around the perimeter of the TT, except for where the tracks will go, to make it look less like a flat plate slapped down on top of the layout.

As it is I'm going to have to add a 2 foot wide by 4 foot angled extension at the end of the layout to accommodate the TT and redo the trackwork in that area.

There was something lacking there anyway and I think the TT was it ![]()

Now to find the best price!

Pulled the trigger and ordered one from Norm's O Scale for a great price.

Time to redo the redo on my track!!!

Let's see some more photos ![]()

I will probably do the same, but since I am still working on starting the

benchwork, it does not need to sit in a box! >GRIN>

Dennis

Dennis

Piscataway, NJ

On Tue, Aug 19, 2014 at 4:18 PM, O Gauge Railroading On Line Forum <

alerts@hoop.la> wrote:

Bob

Are you going to use toggle switches or cab 1 2 for the tracks coming off the TT?

This is in reference to controlling power to each of the tracks coming off the TT for parking a engine.

I'm just asking because the TT has a reputation from all that I have read that applying high voltage to turn the TT tends to through the little belt off the TT. It soon becomes a PITA.

If you would like I will send you pictures and info of the Atlas (item311) AC DC small transformer that is a real neat little tool for running this TT. You can really fine tune the amount of volts and avoid a bunch of problems. Just a suggestion for ya.

good luck on the project.

Larry

Larry,

I can do it either way, really haven't thought about it yet.

How much voltage is required? I have a couple of transformers I can use, an old Troller Transamp 1 (1 amp) with fixed AC and variable DC, a Z750, and an old American Flyer 1A. Don't know if any of them can do the job, but I also have DCS, and CAB1-L/Base1-L, powered by a PH-180.

Send me what info yo have and I'll take a look, thanks!

Well Bob...It was a busy day for me so didn't get a chance to come back here until now...but...it seems too late for me to answer your questions as the guys have come through once again in helping you!!![]() . That is what is so great about this place!!

. That is what is so great about this place!!

Bob...if you go online and take a look, you will find that there are folks that have done a lot of things to make the turntable look more prototypical. In fact, Atlas says that they modeled it after a Santa Fe prototype although I could not find which prototype of which they speak. Glad you found one and I know you are excited about it!!

Alan

Bob

Are you going to use toggle switches or cab 1 2 for the tracks coming off the TT?

This is in reference to controlling power to each of the tracks coming off the TT for parking a engine.

I'm just asking because the TT has a reputation from all that I have read that applying high voltage to turn the TT tends to through the little belt off the TT. It soon becomes a PITA.

If you would like I will send you pictures and info of the Atlas (item311) AC DC small transformer that is a real neat little tool for running this TT. You can really fine tune the amount of volts and avoid a bunch of problems. Just a suggestion for ya.

good luck on the project.

Larry

Larry, if you could send me the pictures and the info on the Transformer Modification for the turntable. Thank you in advance, email is in my profile.

Hi Larry,

Would it be possible to send me the pics and info also. My email is in my profile.

Thanks,

Bob

Alan,

I did a search and found quite a few things, thanks.

I almost went into the "build it yourself" mode, looking for ball-bearing turntables and Lazy Susans to convert. Then I thought of all the effort involved with no guarantee it would work, that's when I made the call to Norm. Some of the photos I saw made the Atlas TT look much better and I see an ERR Mini Commander can be hooked up to it (anybody done this?). There was also an article on a direct drive (no belt) but I couldn't determine where to buy the motor/gearbox.

Here's what my layout looks like now:

And here's what I've designed for the TT:

All I need to do is add a 12" to 24" x 8' extension along the side, I won't have room for a roundhouse but that's fine, an engine shed will do. I can't go more than 24" wide on the extension (stairway and access).

The TT will give me a bit more "play time" at this end of the layout (I'm glad I never finished the scenery in this area) and the TT is the only thing I needed to buy.

Come on guys, more pictures! I know there's more than a handful of these things out there ![]()

Attachments

Guys I can't find my manual anywhere. But, if when you get a atlas 6910 I think you will get a better idea why I was going to use this or a similar type transformer for the TT power source. Or you may not.![]()

This is a few pictures of the atlas 310 & 311 transformer. I understand it came with ho and n gauge sets. I bought this one on the bay new 25 dollars shipped. Not real hard to find.

Now I typically use this for testing various AC or DC lights. I did get it for the TT but that project didn't work out due to space.

Atlas power pack transformer. Great for running switches and accesories. Features on off switch direction control and throttle nob and overload indicator. Input 120VAC 60HZ 25W Output 17VAC

0-14 VDC max 10VA total max output 15VA.

Larry

Attachments

Very nice Ted! I figure I'll paint those "blocks" on either side of the track locations, but not sure if I want them to stand out or blend in ![]()

Bob

Just a little reminder. You can have parking spaces off the TT 50 feet long, but you can't park anything more than 24 inches long or less coming off the TT. Unless of course you plan on multiple engines on the same parking track.![]()

Larry

Frank,

I'll have room for 3-4 engines near the TT and a switcher parked inside the Wye. That's plenty for me.

I did revise things a bit:

This will keep most of the existing track where it is, just have to tie-in the TT once I extend the framework.

Attachments

That does look like a good play area.

I'm curious, where's your modelled bridge across the Atlantic ocean? That

London, Midland and Scottish Ry locomotive has me confused, it's not a Coronation class that i can tell, I'm unsure what that is

I watched the video Lionel put out on how to control the Atlas TT by installing an ERR Mini Commander and making it appear the TT is just another engine.

I have 2 old Locosound modules (1 steam, 1 diesel), shouldn't I be able to do the same thing? It won't fit inside the TT shack, but hey, I can always "build" another building.

Can't do it, at least not in Command Control. The Locosound module is conventional ![]() .

.

I'll get the TT install and then decide how to power/control it.

What is the diameter of the largest outer ring on the Atlas TT? If the TT itself is 24" then the outer ring has to be what, 26"?

I'm chomping at the bit here and want to get a head start by having the frame work in place when it arrives.

I had one of the HO versions of these, which I disliked because of the lack of a pit, but think I then saw a photo somewhere of a short line or mining road? that had a

prototype with the pit boarded over....no idea now where I saw that. Seen that? If I was to incorporate one now, planned, but space where planned does not now look to allow it, I would have an armstrong (1/4" and full scale, me), and a gallows type.

Got it yesterday!

Word of advice...GET the TT BEFORE you build layout space. I added a 12" extension to the side of my current layout and the TT barely fit where I wanted it.

But fit it did! I placed the hand crank on and gave her a crank, jammed ![]()

![]()

I played around with it for 5 minutes before I decided to take it apart to see what was the matter.

I removed the center screw and the TT comes apart in 2 pieces. There's 2 plungers that make contact with the track power that had fallen out (don't think this was what was causing the jam) but they went back in just fine.

What I think was the problem was the cam gear was jammed. This IMO is a very poor design, the cam gear simply sits in a hole in the bottom section and a cover plate on top is suppose to keep things in place.

Problem is all this stuff is plastic and as big as it is it warps/bends/sags. The plastic cam gear HAD a spindly little shaft/pin (plastic) that was suppose to go in a hole in the cover plate, well the shaft/pin was broken.

I fixed it by drilling a hole thru the cam shaft center and inserting a tiny screw with a larger flat washer on the bottom of the TT, with another flat washer and nut on top of the cam gear. This keeps the cam gear from coming out of the hole in the bottom section. I may even drill a hole in the cover plate and move the top nut and washer there so the gear is captured between the bottom plate and cover plate.

I hope Atlas reads this.

I powered it up using my old Z750, but I'm wondering if a wallwart can be used (seems like a small motor to be turning such a large platter, but so far so good). I have a few laying around so I may test to see which one will do the job.

Once I get it running like I want it then I'll do some weathering to make it look less like a large plastic trash can lid!

Here's a photo, you can see I cut it close on the surrounding space:

Attachments

I had one for a while but wasn't very happy with it. The drive belt was constantly falling off.

It came with a spare belt, which I had to replace immediately. The belt that was "on" it was off one of the pulleys and when I took it out it looked like a pretzel.

Bob,

Could you take pictures of your fix?

I will be getting one and will probably have to do it!

Thank you in advance!

Dennis,

I currently have the TT fastened down on the layout, but here's some photos of it with the cover plate off:

I used a #2 button head machine screw 1/2" long. There's a large #2 flat washer on the bottom (head of the screw) followed by the large #2 flat washer and nut you see on the top in the photo.

I drilled a tap hole for the #2 screws using a #50 (.070") bit in the middle of the cam gear (there's a nub on the bottom of the cam gear, maybe 1/4" diameter) and tapped the hole for the #2 machine screw. I figure if it's tapped all I needed to do is screw in the screw until the gear can't move then back it out a bit so there's no resistance when the cam gear is turned. I put the nut on the top for safety's sake, but it may be one more piece that could gear inside and mess things up.

The hole doesn't have to be perfectly centered as it's only there to keep the gear from riding up, but I tried to get it as close to center as possible.

I used a button head screw because it has a very shallow head and won't affect the flatness of the TT. If it does a small clearance hole can be drilled in the layout tabletop to clear the screw head.

Goggle Button Head Cap Screw and you'll see what they look like. I get mine from Microfasteners:

http://www.microfasteners.com/...rew-alloy-steel.html

While I had it apart I also applied some white Lithium grease to the gears, made things run smoother.

hope this helps, if I have to pull the TT back off the layout I'll take some bottom photos, but this should do it.

Attachments

Thanks Bob! Post if you do end up taking it off the layout.

As for the speed, I use about 4 - 5 volts & works great & more realistic. Very nice piece for the price. As for a longer engine, I line it the Round House & exiting track & just run it across it to park the longer engine in the Round House. I line up tracks as close as I can without them rubbing to turntable.

John,

I just tried a wallwart that has different voltage settings of 1.3, 3. 4.5, 6, 7.5, 9, and 12 vdc and is rated at 300ma. I tried it at 12, 9, and 7.5 and so far it works fine. Still need to power the tracks and get the leads into the TT shimmed down to match the track on the TT.