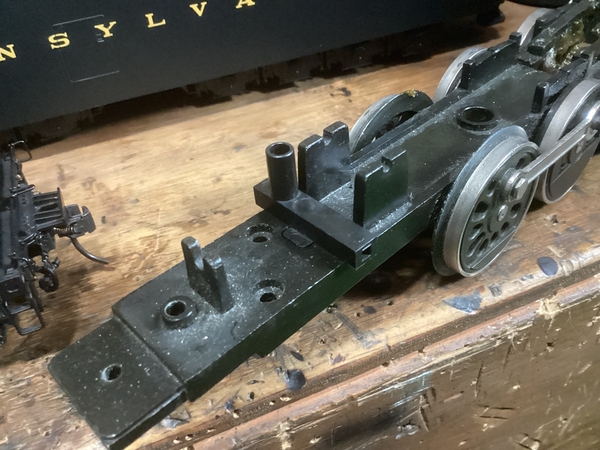

I’ve rebuilt dozens on top of dozens of these Mohawks, both the 18009, & the 18064. The problem we need to address is to get to the root cause first, so is this a traction problem you’re having ( wheels just sit and spin ) or lack of pulling power, ie; you can’t supply enough voltage to pull your desired train. This locomotive should have no issue pulling your desired consist on level track with generous O72 curves. If you’re having traction issues, let’s look at the trailing truck, and the pilot truck. If they have too much tension sitting on the rails, they can lift the drivers just enough to cause tractive problems. I’ve seen the pivot arms of the pilot trucks bent just enough to cause this issue, as well as misaligned ash pans causing the trailing truck to lift on the back of the locomotive. When the locomotive is sitting on the rails, you should be able to lift in the pilot truck and the trailing truck and neither should begin to lift on the chassis. You should only feel very slight spring resistance on both trucks. Just enough to keep each truck seated against the rail head.

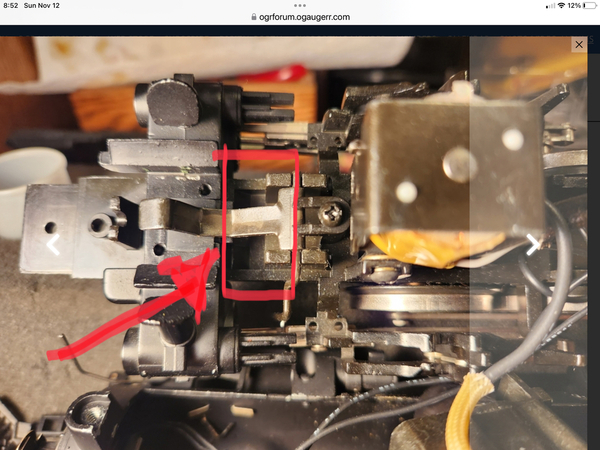

Performance issues can be diagnosed by your Z4000 for you. If your engine is drawing too many amps, then it’s working too hard to even pull itself, let alone a consist of cars. A properly tuned Pulmor motor equipped Mohawk should consume between 2-2.5 amps ( smoke unit on ) to get itself and the tender moving ( running light, nothing else on the rails ) ……..if you’re engine is consuming a lot more amps than that, then it’s time to open her up for an examination. Both of these locomotives 18009.& 18064 respectively, are notorious for the grease hardening in the gear box to the consistency of cured concrete. They were also sometimes very kind enough to squirt that same grease in the oiling ports of the Pulmor motor. If you suspect an amperage consumption problem, first remove the shell, and try and rotate the drive line by hand. A properly tuned Mohawk should spin like butter. There’s other things to consider, but let’s check the usual suspects first, then dive in even deeper if necessary …..

Pat