Where can I find a list of Locomotive Workshop Diesel Locomotives Brass and White Metal Kits and Accessory Kits on the Internet?

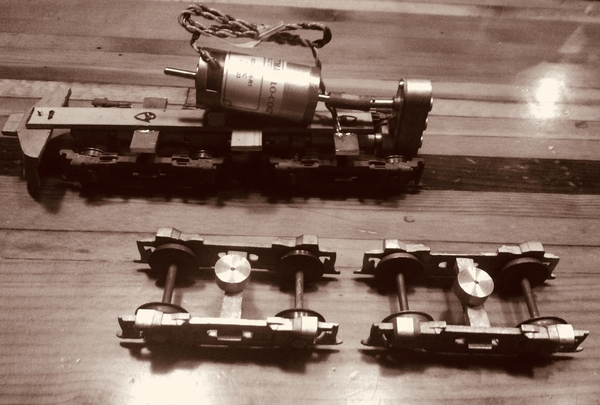

The Locomotive Workshop O-Gauge 2-Rail Diesel Locomotive line of Kits was owned and made by Jan A. Lorenzen during the late 1960s to 2000s. These Diesel Kits came with basic parts made from cast White Metal and Brass and require an intermediate skill level and tools to assemble.

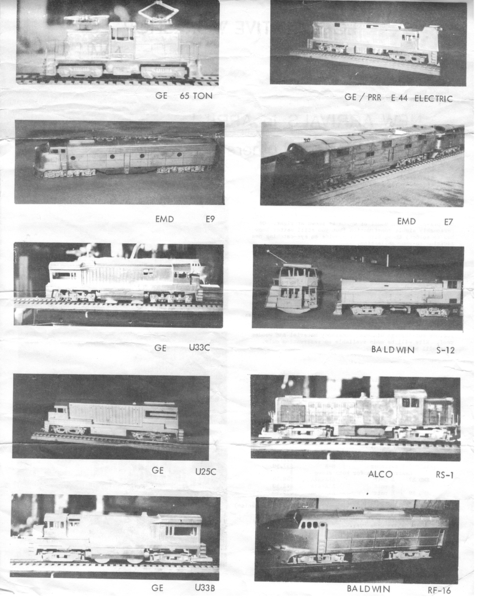

I found a Locomotive Workshop (LW) product announcement sheet (?date) that describes some of the Diesel Kits in the 1980s... Which other Locomotive Worshop Diesel Kits were manufactured and not included on the following list? I know they made a Baldwin Centercab that is not listed below...

Regards, Steve Neago

Cincinnati, Ohio

LOCOMOTIVE WORKSHOP

32650 LAKE ROAD

AVON LAKE, OHIO 44012

(216) 933-4142

JAN A. LORENZEN

NEW ARRIVALS in APRIL!

SD40, GP40 and others in 0 Gauge!

*all brass superstructure

*fully engraved/etched

*formed hoods and cab

*lost wax castings by Kemtron

*truck castings included

*full instructions

Our newest diesel kits are for the EMD 40/38 series, the pre-production model of which is shown at right. Of reasonably simple construction (but you still better know how to solder) these kits will provide an eye-catching new addition to your collection.

GP40, complete, less power $75.00

GP39 ditto $75.00

GP38 ditto $73.50

SD40 ditto $80.00

SD39 ditto $80.00

SD38 ditto $78.50

SDP40 ditto $85.00

These are for the "base" EMD engine, less extras.

The following lists available accessory kits or "parts packages" where available:

Aluminum Casting Sets

Baldwin RF-16 "Sharknose" B-B $37.50

General Electric U25C C-C $37.50

General Electric U33B B-B $37.50

General Electric U33C C-C $37.50

GE Pennsylvania E44 electric C-C $45.00

GE 65 ton switcher B-B $17.50

Photoengraving Sets (Brass)

ALCO RS-1 road switcher B-B $37.50

ALCO S-4 switcher B-B $37.50

Kemtron parts for above Kits:

EMD E7 A unit A1A-A1A $49.50

B unit A1A-A1A $42.50

EMD E9 A unit A1A-A1A $59.50

B unit A1A-A1A $52.50

(Note E9 and E7 basically complete except for mechanism)

Baldwin 1200 hp S-12 switcher B-B $37.50

Brass parts to complete

GE-UP Gas Turbine "Verandah" (O-Scale) $45.00