Looks great George!

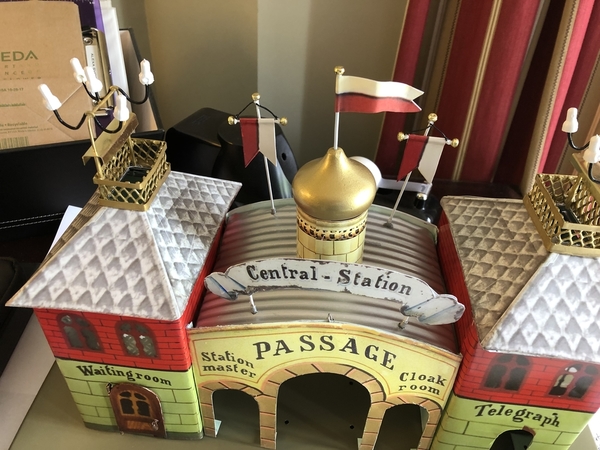

This side is mostly finished. Just needs two telegraph insulators below the roof line and a door knob. I am using resistors painted brown for the door knobs.

Here is the railing inside the passageway in front of the ticket counter.

I still have two doors to make for the other side. Here is how I make the doors. I am using brass for this because it is easier to solder the hinge to it. I had trouble soldering the tin. Maybe it would work with tin if I had a tin hinge?

I am going to put the passenger fence/track barrier on the opposite side. The original had the fence on both sides, but I will be having tracks on only one side and it will be along the back. I have seen many examples with the fence missing altogether.

The final work will be doing some paint touch-ups on the inside. Spray my rattle can colors into a small plastic cup and brush the touchups by hand.

Hope everyone is enjoying the journey. I appreciate the kind words and suggestions!

George

Attachments

I'm betting the "tin" wasn't a pure enough metal and/or wasn't clean enough. Pre- fluxed?

Tin is part of many solder alloys (%) and solder should stick easy to it.

FYI, this has inspired something here also George.

What exactly, I'm not sure yet. I don't usually plan so much as I "just build". (The salt container may or may not be a mold for pebble & cement (or plaster) tower. Same with creamer containers and couch legs.

Anyhow a few days ago I spotted this finial on a hutch being tossed out, and thought of this thread. I dismissed using it at first until I noticed the flat on it's backside and saw "a clocktower".

So I twisted it out to take it home. I cracked open my smallest dead watch (cheap batt. op Coleman) for the face & hands, broke out the Forstner bits and drilled a hole, following with some Old English dark polish on the fresh wood. (dry, thirsty old wood. It was really eager to drink the oils up.)

A smaller diameter womens watch would have fit the bill better. I might have even been able to re-use the crystal or grind the strap bosses off the body to retain some trim.

No building yet, but last night after looking at a figure for a photo shot, I also made a rustic arched door out of popsicle sticks & 2-staples; one for handle, the other for the latch's thumb button. I likely do another door and darken this one more tonight.

I think you can manage some fairly ornate handle shapes from heavy duty staples. Longer ones would be way easier to work with too; just clip the "handle" when done.

I really like wood and so may not paint over it, even though it's not "ideal' being woodgrained. I'm thinking maybe I'm going to try some traditional gilding here to offset the look with some metal. Gold ball, roof, base?..Only maybe. A visor lip over the clock, painted or actual, might be enough though. I might wack the ball off and "sharpen" it too.

I've only done gilding a few times as an adult, and it really wasn't done "traditionally"; like it was when I was a kid with my Grandfather (His father did it professionally.

Attachments

Outstanding, George! A very nice display of ingenuity.

Adriatic, that’s very neat! I read about some Marklin stations that many had working clocks in them with clockwork mechanisms that still function today. It will be fun to see how you finish this.

George

I'm guilty of "short attention span theater" on projects. E.g. I shelved a GG-1 I cut in half for the GG-½ ice blower for three or four years, then finished it as fast as drying glue and paint allowed. Real cars would also sit rusting for years, then be finished enough for shows in 1-2 months...etc.etc..

So no telling when it will get done. I'll shelve a project for years sometimes before coming back to it; waiting for "the answer" to make itself known...or until I get tired enough of waiting and just "settle". My saving grace is I do get back to them for the most part.

I won't likely forget my inspiration either though; so you'll be first to know it's done... if I don't end up posting the whole build along the way ![]() ...and thanks for doing that by the way.

...and thanks for doing that by the way.

Incredible, George. And, it's nice to see somone make such consistent and steady progress. It's definitely time to step back and be proud of your accomplishment.

The colors, shape, and so much about that station really "pop". I'm curious, 'though, on how you created the door hinges. Are they just metal loops that hold the ends of the soldered wire pins in place (per your prior photo)?

Tomlinson Run Railroad

(The inside railings are great, too.)

TomlinsonRunRR posted:Incredible, George. And, it's nice to see somone make such consistent and steady progress. It's definitely time to step back and be proud of your accomplishment.

The colors, shape, and so much about that station really "pop". I'm curious, 'though, on how you created the door hinges. Are they just metal loops that hold the ends of the soldered wire pins in place (per your prior photo)?

Tomlinson Run Railroad

(The inside railings are great, too.)

The door hinges were a challenge. They are modeled more after a Lionel reefer than a Marklin station. I never saw a real Marklin station to figure out how they made theirs and my doors are bigger than the opening, unlike Marklin. This was my “artistic license”.

So, I first tried a tube that captured the end of the pin, but I couldn’t cut it and bend it to attach to the wall without deforming the tube substantially. I then used the “keep it simple - KISS” approach. I cut a small strip of brass and folded it like a ‘U’ shape. I pressed it around the hinge pin with my needle nose pliers. This was inserted through the wall and fanned out on the opposite side.

Cutting a hole in the side of the tin was also a problem. I drilled two small holes next to each other for each hinge. I then used the drill to join the holes. I could not use the Dremel for this, since the slot was so small, and I could not use a punch, because I waited until the building was assembled. Last problem was my hinges were too big for the hinge openings. The Dremel cutoff wheel cut the brass like butter. I held the small hinge with my needle nose pliers and shaved off a 1/32 inch of the hinge flange.

I’m happy you noticed and glad I found a solution.

George

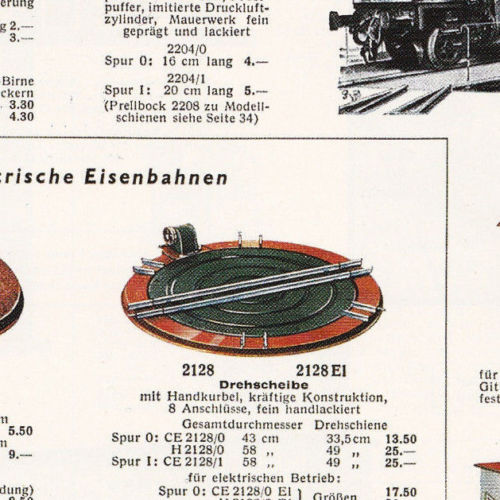

George, that is pretty impressive I have to say!! I can't remember if you ended up moving or not, but either way, you will be itching to get that station down on a layout!! I'd really like to build a tinplate turntable like the early Marklin or Bing or one of the other accessories as well. It would be an interesting project to make a big turntable like this one in tinplate. I can see the need to visit my buddy with the bead roller!

Attachments

One of the two rail scale guys made one out of an 18" kitchen pan....I do apologize, as he is a member of this forum and of course these are his pictures, but you get the idea.

Is that a cabinet Susan or one for a chair?

Attachments

not sure. My late Uncle Jim had bought a back hoe (project of course) and I went up one day, and he had the seat apart. The swivel mechanism was shot, and he had found an excact replacement at Home Depot. I took one look at it and said that would make a neat turntable. Next time I was there he had picked one up for me.IIRC it was around $25.

George,

Thanks for the description of your door hinge solution. I like that your doors are a little larger. It looks good and probably helps with opening them, too. Your use of "tabs" for securing the brass hinge fits the period and is simplicity itself (KISS). Thanks again.

Tomlinson Run Railroad

Dennis Holler posted:George, that is pretty impressive I have to say!! I can't remember if you ended up moving or not, but either way, you will be itching to get that station down on a layout!! I'd really like to build a tinplate turntable like the early Marklin or Bing or one of the other accessories as well. It would be an interesting project to make a big turntable like this one in tinplate. I can see the need to visit my buddy with the bead roller!

I found a spur 1 version of the Marklin turntable in the UK for about £49. At that price you would be better off buying one. However, I didn't find a spur o one yet.

George

That is a very impressive piece of work George - Well Done!

Dennis Holler posted:George, that is pretty impressive I have to say!! I can't remember if you ended up moving or not, but either way, you will be itching to get that station down on a layout!!

Hi Dennis,

We never moved. The house didn't sell. I moved my layout to my parents while the house was for sale. Now, I need to move it back. I'm prepping the basement for a proper layout. We had a power outage last year and the sump pit backed up and flooded, just a few inches. I am installing a generator to prevent that in the future. I'm also considering putting foam insulation on the concrete walls to warm it up a little down there. I don't want to go to the expense of fully finishing it. Anyway, I am anxious to get it built so I can put all the items I have collected and made over the last few years on display.

George

George, I am always impressed by your resourcefulness and creativity. I just surfed over here from a current photo thread. Your station is truly a work of art.

I do have a philosophical question, though. I know you are using tin because the original was metal. But I can see it is hard to work with and keep flat. Since you are covering it with photos anyway, what about making the building from wood or masonite? The look would be the same and it seems it would be a little easier. I would myself probably prefer that. But then I am a woodworker by trade.

I forget what you said you seal it with? Krylon makes a UV protective spray. Photos will fade over time.

Anyway, I might steal your idea of the photographic lithography one of these days.

@Will posted:George, I am always impressed by your resourcefulness and creativity. I just surfed over here from a current photo thread. Your station is truly a work of art.

I do have a philosophical question, though. I know you are using tin because the original was metal. But I can see it is hard to work with and keep flat. Since you are covering it with photos anyway, what about making the building from wood or masonite? The look would be the same and it seems it would be a little easier. I would myself probably prefer that. But then I am a woodworker by trade.

I forget what you said you seal it with? Krylon makes a UV protective spray. Photos will fade over time.

Anyway, I might steal your idea of the photographic lithography one of these days.

Hi Will,

Thank you.

I am using Kylon Preserve-it Photo spray to seal the photos. I would think Masonite would work. For the onion dome, I wanted a thin material and I wanted it to be close to the original style. The inside of the onion dome is painted. If you choose Masonite, I would use a different glue. I recently used Best-Test Paper Cement. I think that would be a superior option on Masonite.

George