does anyone have a write up for modifying a post war relay to isolate the frame of the relay from ground?

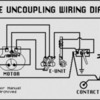

I’m trying to use a whistle relay to open some electro couplers on a postwar 624. I have 2 relays so I can start with one in case I mess it up.

My basic plan is to remove the coil wire from the back of the relay and extend it to ground then isolate the relay from the mountin frame so that I can wire the coupler wires across the contacts.

Is there an easier way to do it?