Saw this on a new DVD Twentieth Century Limited

Replies sorted oldest to newest

![]()

Awwww ......???? Ummm.... Photoshop!

Looks like that's right on time with me...

my NYC hand car??? ![]()

Of course that's on the NYC RR near where Josh Cowen grew up and lived. So, now i understand where he got the idea, in 1906, for his three rail track introduced that year!

Paul Fischer

"When the New York Central electrification project began the railroad decided on a 660-volt, direct current (DC) system employing third-rail, similar in nature to what the Baltimore & Ohio Railroad had used for its Baltimore Belt Railroad project a decade earlier (the NYC looked to the B&O’s project for guidance when constructing its own electrified lines)."

Engineer-Joe posted:"When the New York Central electrification project began the railroad decided on a 660-volt, direct current (DC) system employing third-rail, similar in nature to what the Baltimore & Ohio Railroad had used for its Baltimore Belt Railroad project a decade earlier (the NYC looked to the B&O’s project for guidance when constructing its own electrified lines)."

Except that was outside third rail, not center third rail.

This picture came up about a year or two ago, as I recall, it was pretty much determined that the third rail was a guard rail for the approach of the track pans.

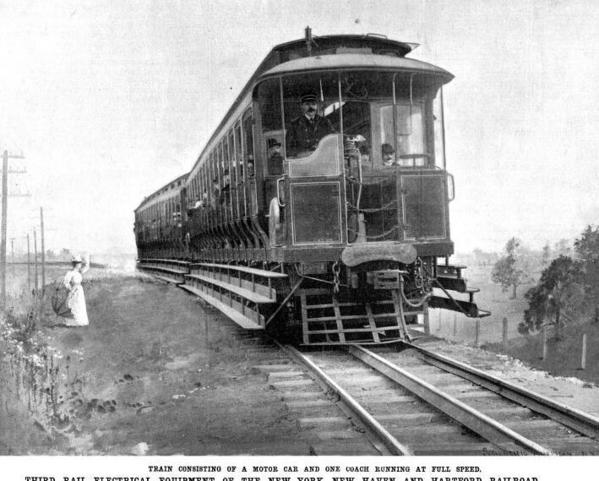

However, the New Haven did have an active third rail at one point on the Nantasket line in 1895:

Rusty

Attachments

Thanks! I couldn't find the exact info.

It looks like they used Atlas rail joiners too. ![]()

fisch330 posted:Of course that's on the NYC RR near where Josh Cowen grew up and lived. So, now i understand where he got the idea, in 1906, for his three rail track introduced that year!

Paul Fischer

Sorry Paul, that was Maerklin in 1897.

Lou N

More info on that NH Nantasket line...how much voltage did that rail carry ...and was it a hazard?

Looks like a diorama to me. No lines on telephone poles.

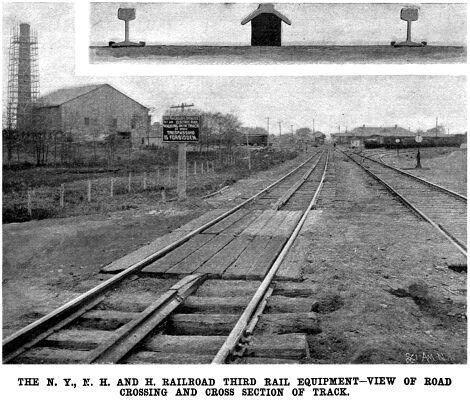

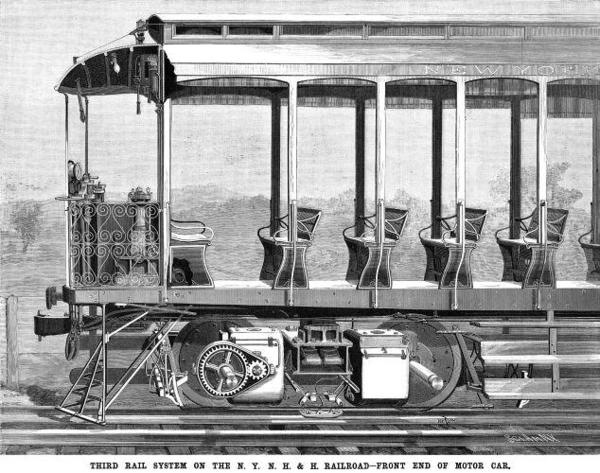

I believe the New Haven Nantasket third rail electrification was at 650 VDC. There were a number of fatalities associated with the operation. The New Haven put out a document indicating how safe the operation was and the only fatilities were trespassers. This was a GE electrification and there is a fair amount of information on it, including photos, in the GE archives at the Schenectady Museum.

Wait, I'm really messing up here. Is that real or toy??? ![]()

Both are real. NYC used a center guard rail to prevent the tender water scoop from tearing up the track, and the scoop, if it was lowered too soon. The New Haven electrified one of their branch lines with a center third rail. It was not successful because there was no way to cover the center third rail and it turned out to be too dangerous.

The photo is real its a video, I paused the video and took a photo. What I thought right away, how cool NYC Hudson on 3 rail track (all rails the same size and middle one centered) just like my first Lionel.

Clem k

Yep. Dual gauge. Or is it duel gauge? ![]()

Great prototypes folks! At the risk of awakening the center stud contact debate again, I give you the Doulter stud system which produced the occasional dead horse and/or pedestrian. It didn't last long .

https://en.wikipedia.org/wiki/Stud_contact_system

http://www.swehs.co.uk/swehs-trams/xx12b.html

Also, if you get anyone pointing out your two-rail trolleys don't have any overhead wire, just say it's a Mekarski compressed air system.

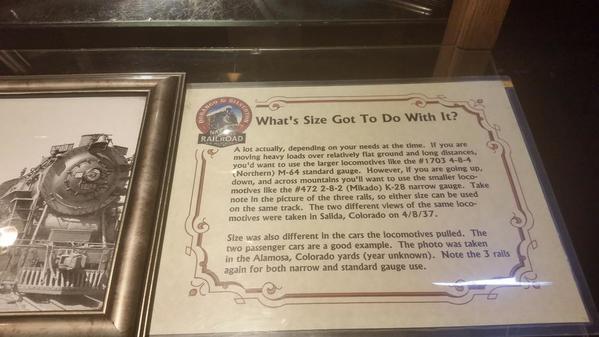

Uh, Colorado narrow gauge often had an outside third rail added to get standard gauge trains into its territory. Middle rail was not centered. There are famous photos of "the end of third rail" (standard gauge) with only the narrow track continuing to distant mountains, and signs posted.

I've often thought about dropping the third rail all the way to below the tie height and have it as just a thin strip similar to that used on Super-O. Of course, all your rollers would have to be low hanging and it would probably only work as a drag roller operation rather than a push roller. But it would be worth experimenting with. Just imagine how realistic the track could look if the third rail was at ballast height.

Penny: For many years Marklin trains ( HO gauge -German built trains) have used what they call a "stud 3rd rail system". The 3rd rail contact is a small button located in the center of each tie. The pickup on the engine is a long sliding contact bar that hits several of the 3rd rail buttons at the same time. This contactor bar is on springs an moves up and down a great deal, so it is always in contact with one or more contactor buttons. At switches, the track has ramps that move the contactor bar above the rail height so as not to short out. They have had this basic system for many years and while they have changed their track design over the years, trains from 50, 60 or 70 years ago all still run fine on the newer tracks.

Incidentally, Marklin trains also operate on AC power. Their sequence reverse system works more or less opposite of regular Lionel, AF or Marx systems. Instead of interrupting the power to trigger the reverse, their reverse is triggered by a momentary higher voltage shot so their trains are not as subject to erratic reversal as ours are. Of course, Marklin has been embracing more modern electronic systems which are controlled totally differently, just as our digital command control systems now function.

Paul Fischer

That's where I got the idea.