If the spring is shortened sufficiently, its free length will be shorter than the gap and there will be zero preload on the spring until the pickup roller is displaced upward and the spring begins to be compressed. In this case, it's not the spring rate but, rather, the preload that is important. The longer spring causes a larger (downward) preload on the pickup roller. Shortening the spring will reduce the preload and allow the pickup roller to be displaced upward (by the middle rail) more easily. The spring itself is designed to operate in the linear range (force = k * x) irrespective of its compressed length, but the initial preload is what determines the vertical motion of the pickup roller, not the spring-constant (stiffness). Shorter spring = less preload = more vertical motion of the pickup roller.

MELGAR

Except isn't the point of using a sprung roller to have preload on the spring? If there is a gap that allows vertical motion of the roller before the spring is engaged, doesn't that increase the risk of flickering lights, and perhaps more importantly, arcing? And, if roller is deflected so much that the shortened spring is engaged, wouldn't you then have the same problem, especially with a greater spring constant? Wouldn't the better solution be to either use a spring with a lower spring-constant or add weight to the car?

Edit to add:

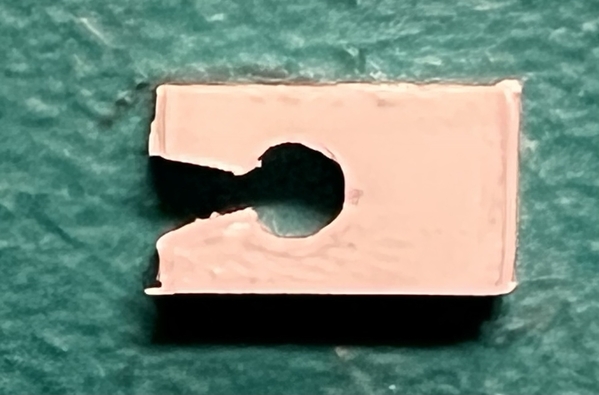

I don't think that the spring preload is the issue. The spring's wire gauge and length appear to be comparable to all my other cabooses with the same basic vertically-sprung pickup roller, which is all but two of my cabooses, these include Lionel, MTH, Atlas, and Weaver. The spring stiffness also feels comparable. (Admittedly, the differences are too subtle for me to detect.) The outstanding difference is that, as someone pointed out earlier, I believe, the column inside the spring is plastic. Perhaps the increased friction between the metal bracket holding the roller and the plastic column are significantly increasing the resistance to vertical travel of the roller, especially when a lateral force is applied as the car moves on the track.