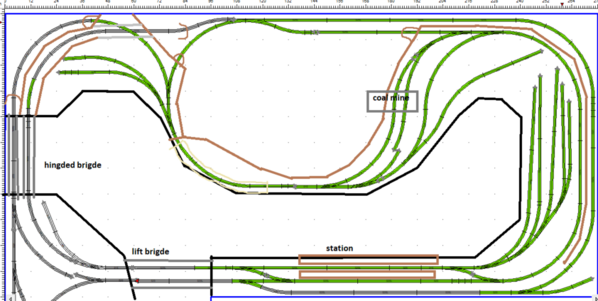

The time has come, i can now join in with all of you. So the wife and I just bought our first house. The first floor remodeling is now done, moving onto the basement now. I have 23x11 to work with if a little extra for the bottom left. Still in rough planning but im pretty happy with this plan so far. After a talk with the wife on what she'd rather have. More trains running at once or a more realistic look. She chose realistic so this is what we came up with. 072 curves other then any of the curved switchs, which will be 72-54. I decided to give the look of a double main line, but have a good travel loop time. So on the back side of the layout the track crosses over its self. To help with the grade im going to split the difference between both tracks. Planning on including the following industries, these are a must have.

Coal mine - already located

Power plant - thinking top left side

Fisk tire - still planning

So now its on to the prep work in the basement. Take out the old furnace, fix issues on the block foundation, pull up asbestos floor, framing, and drywall. Then i can start the bench work.

Let the fun begin.