@BillYo414 posted:More progress on track and table. Most excitingly, I managed to level out the bowed pieces of plywood to the point where I'm satisfied! I ended up going with a 2x4 on the underside.

I bought some terminal strips to start getting setup for wiring but setting up track and putting up more table really sucked up most of my time. I was surprised. My layout uses a few sections of custom track or flex track and that was an unexpected difficulty for me. I'm used to sectional track where you put it down and go. So I've had to do a lot of measured and double checking before I screw the track down. No big deal. I would say I acquired a new skill!

On with the photos...

here is my newly un-bowed plywood:

I really like the track work here and that's mostly because it took forever to get the alignment where it should be:

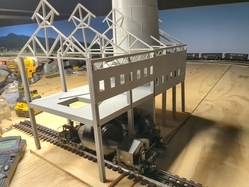

And here's some of those fun double track mainline shots:

You may notice the 2-10-10-2 isn't on the tracks. It seems to have chewed up its own gearbox. Not sure what that's about but I'm looking into it.

I cannot seem to get the casting deck for the blast furnace to print no matter what I do. It either warps or comes out looking terrible on the corners. My last two solution ideas are keeping the bed temps elevated through the print or replacing the nozzle. The casting deck is kind of important to holding the structure together in the model so splitting it into smaller pieces would be trouble. Kind of a bummer. I wanted to start putting the furnaces up. I did get the highline arches and girders prototyped. They look great but I want to get a few more done before I show off haha

Bill, the mill works will be on the way. Despite the setbacks it must feel good to get some track down. And, as Peter mentioned, the backdrop works.

Jay