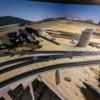

Pretty solid week of construction given how little time I've had to spend on the model railroad. This end of the table required a 1'x8' section to fit the big bend. I had some help and got that built and installed. That's exciting because it means one end of the main loop is complete.

I'm particularly pumped to have this little sequences of switches. It's a #8 and then a #6. I'm a bit concerned about how anything besides giant steamers will stay powered through them but I guess we'll figure that out. I have not wired these up just yet. I was in a hurry to get them connected tonight. The #8 in the foreground will connect to the yard. The #6 will also connect to the yard but it's more of a run around track and not meant for make-up and break-up of trains. I think I'm going to go with Tortoise switch machines for these mainline switches.

So far so good on clearances still. I still need to measured out the overhang of a Visionline Big Boy. That's rumored to the be the biggest. It's interesting seeing the small steamers get around the big curves because they have very little overhang. As great as things look on this big bends, a lot of it will be covered by a massive hillside to break up the fast that this is a loop. The big steamers that will pull coal drags don't look as good on curves in my opinion, so I will tuck them away in a hill and conceal and access hole at the same time.

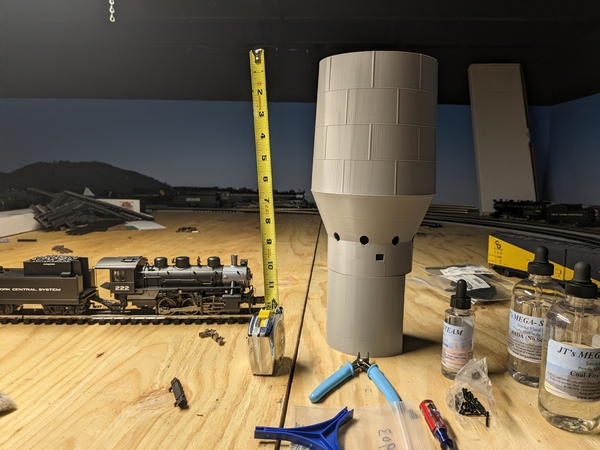

I'm working out final gcode files of the blast furnace and it's structure. I will be building the blast furnaces on the layout as they come off the printer and I'll post pictures. I just can't get over how many hours of printing are going to be tied up in each structure.

I've started on the flywheels for the blowing engines. I know vertical blowing engines would be outdated by the 40s/50s but I just think they're the coolest machines. The size and look is outstanding. It must have really been amazing to see/hear/feel several of them breathing at once. I hope to animate these too but noise is a concern. Plastic sliding on itself can make a ruckus at speed.